4.0 SOHC diagnosis? Rough idle/won't rev

#1

4.0 SOHC diagnosis? Rough idle/won't rev

Hi all,

This is my first post on this forum specifically. I have been on rangerpowersports and therangerstation for ahwhile. I've owned a 98 Ranger 3.0 manual that I learned a lot on, and just got a '04 FX4 Lvl 2 that I am in love with. That's another matter though.

I talked my sister into buying a 2005 Mazda B4000 that has 95000 miles on it. She bought it for $5750. The truck is literally immaculate. It was owned by an elderly gentleman who passed away. His daughter and her husband wished to sell it because they had no need for it (I'm guessing they needed the money bad too...), and it wasn't running correctly and were told by a couple different mechanics they would need to replace the fuel pump for $800. The truck truly is an immaculate truck, inside and out. No rust, no dents, no rips, no corrosion, clean, nothing missing or broken. It blue books private party for around $10k (permitting it runs correctly). Again, she (we/me) got it for $5750, so even if we have to put money into it, we should still come out ahead.

Upon inspection of the truck I knew we were getting into two issues. A fuel issue, and a probable timing chain tensioner issue.

1.) The fuel issue would be easily fixable. I suggested that just a new fuel filter would help enormously, and that it might not even be the pump. It didn't fix it so we pulled the bed and swapped in a new pump for shy of $300. New fuel filter: $13. It still wouldn't run correctly.

2.) The timing chain issue isn't an immediate issue as far as I understand. It will rattle around and make noise, but the truck should still run fine for a while. I would think it is even possible that the rough idle/running engine would exaggerate the chain slapping around, and that fixing one would fix the other.

The problem is the fuel issue/rough engine. The timing chain is for another day (unless collectively it is agreed that it could be the issue all along with the poor running engine). I have read numerous threads about 4.0 SOHC's from Ranger's and Explorer's that deal with rough idles, bad running motors, smoke in the exhaust, failure to start right away etc...

Here is what I have done so far to fix it.

-Replaced fuel pump assembly

-Replaced fuel filter (first "new" one was bad, returned and replaced, now functioning.)

-6 new fuel injectors

-replaced both ECT sensors

-replaced all 6 plugs and wires, and checked for spark at coil packs

-checked fuel pressure at rail now it holds 65 constant and starts immediately

-swapped both the IAC and MAF with the ones from my '04 Level 2, no effect, and cleaned and put back in originals.

-listened for vacuum leak, sprayed around with starter fluid, nothing.

-checked seals while pulling the intake twice

-(other small things I might have forgotten while typing this)

To expand on the previous list:

-After replacing both the fuel pump and filter, we checked the pressure because it still wouldn't run. We can hear the new pump prime, and when she ran it while I monitored the gauge, it rose slowly to 65 PSI. After shutting off, it would fall. I dug into the engine, and while pulling off the intake and hoses on the front passengers side of the intake, a approx. pint of fuel fell out of the hoses and the intake itself. Several of the ports going into the heads became backed up with fuel. Leaky fuel injectors were my diagnosis. Beforehand I checked the plugs and they were pretty dirty, particularly cylinders 1,2, and 4 I believe. I tried cleaning and reinstalling the original injectors, and no luck. We ordered new injectors in the meantime. When I pulled the intake off to remove the injectors I attempted to clean, same thing, lots of fuel, so injectors must have been stuck open, bleeding off the pressure into the ports. With the new ones in, the engine primes and starts up right away without having to turn it over for 10 seconds. No leaks anywhere as far as I can tell. The entire fuel system should be good now.

Before getting to the plugs and injectors we tried the easier stuff: ECT, IAC. MAF. I replaced 1 ECT at first. After looking through my haynes, I could not find which one sent the signal to the PCM, but I found somewhere on one of these forums that is was the grey/red, and grey/xxx (I forget what color now). I replaced that one and it didn't solve it. Now that I put new injectors and everything else in, I replaced the other ECT just to eliminate any doubt that I got it wrong. Still didn't solve it.

For both the MAF and the IAC, we used the ones off my truck which runs just fine, and that didn't help at all. So I cleaned her MAF and IAC with MAF cleaner and put them back on. I also ran the engine with the MAF connected and disconnected. That didn't help.

All the seals looked fine. I checked the brake booster hose, and the elbowed hose that goes from the throttle body right behind the MAF, into the valve cover I think, because I read that hose can cause problems. I inspected the other hoses as well as I could and have not found a vacuum leak.

I still slightly suspect a vacuum leak, because before replacing the injectors, the brakes were very hard to operate 100% of the time. Now after the injectors were replaced and the engine is running a little better, the brakes work normal some of the time, but 50/50 they revert back to operating like they are manual brakes with no booster attached. At the same time though, I don't suspect a vacuum leak, because the damn this is so clean and immaculate. It was definitely garaged, it looks brand new everywhere. It makes my very decent and clean '04 Level 2 look like its been sitting in the ocean for a year.

I guess I should go over some symptoms I have encountered.

-The brake issue. They work, but are extremely stiff much of the time, previously all the time. I know what normal ranger brakes feel like.

-Still slightly rough idle. Before, it would want to die constantly and idle rough enough to jar the tensioner constantly and very bad. Now it idles much better, but still slightly rough, and still dies out coming out of gear into park or revving while in neutral and then letting it fall to idle.

-Every time I change or fix something, I take it up and down the street to see the effect. While in park before and after the injector and plug change, I would be able to get it to rev to the 3k park rev limiter. Sometimes it was harder, but it would still make it. I can do it now as well, but every time I take it out for a drive it is terribly weak. It acts like I am giving it no throttle, and sputters some too. I will be pegged to the floor, and the engine will slowly get to 2k, then 2.5k then it might act for a second like it hit a rev limiter, and drop really fast back to 2k and it just repeats this constantly.

I should add in that the street where I test from my driveway goes uphill, and I go about 200 yds before turning around in disappointment each time ! On the downhill, via our friend gravity, the engine will rev up to 3-4k, but not under its own power. What the heck is the problem and the next logical step to investigate? Now that I think about it, I haven't checked the TPS sensor I think. I'll go fiddle with it here in a moment.

! On the downhill, via our friend gravity, the engine will rev up to 3-4k, but not under its own power. What the heck is the problem and the next logical step to investigate? Now that I think about it, I haven't checked the TPS sensor I think. I'll go fiddle with it here in a moment.

Overall, it has gotten better, but the issues still persist. Is this related to the timing chain rattle I can hear, or is that a separate issue like I think it is? FYI, the rattle is definitely coming from the front drivers side chain, got lucky there, so when I fix it I don't have to pull the engine.

I've been working on this for almost 4 days solid now, and could really use some help. I am no stranger to the search function, but it has only gotten me so far. Help me give this Ranger "redheaded stepchild" some new life for my little sister and her dog!

A huge thanks to any help in advance, and sorry for the extremely long post!!! I probably forgot a few things, so there is more to come possibly .

.

This is my first post on this forum specifically. I have been on rangerpowersports and therangerstation for ahwhile. I've owned a 98 Ranger 3.0 manual that I learned a lot on, and just got a '04 FX4 Lvl 2 that I am in love with. That's another matter though.

I talked my sister into buying a 2005 Mazda B4000 that has 95000 miles on it. She bought it for $5750. The truck is literally immaculate. It was owned by an elderly gentleman who passed away. His daughter and her husband wished to sell it because they had no need for it (I'm guessing they needed the money bad too...), and it wasn't running correctly and were told by a couple different mechanics they would need to replace the fuel pump for $800. The truck truly is an immaculate truck, inside and out. No rust, no dents, no rips, no corrosion, clean, nothing missing or broken. It blue books private party for around $10k (permitting it runs correctly). Again, she (we/me) got it for $5750, so even if we have to put money into it, we should still come out ahead.

Upon inspection of the truck I knew we were getting into two issues. A fuel issue, and a probable timing chain tensioner issue.

1.) The fuel issue would be easily fixable. I suggested that just a new fuel filter would help enormously, and that it might not even be the pump. It didn't fix it so we pulled the bed and swapped in a new pump for shy of $300. New fuel filter: $13. It still wouldn't run correctly.

2.) The timing chain issue isn't an immediate issue as far as I understand. It will rattle around and make noise, but the truck should still run fine for a while. I would think it is even possible that the rough idle/running engine would exaggerate the chain slapping around, and that fixing one would fix the other.

The problem is the fuel issue/rough engine. The timing chain is for another day (unless collectively it is agreed that it could be the issue all along with the poor running engine). I have read numerous threads about 4.0 SOHC's from Ranger's and Explorer's that deal with rough idles, bad running motors, smoke in the exhaust, failure to start right away etc...

Here is what I have done so far to fix it.

-Replaced fuel pump assembly

-Replaced fuel filter (first "new" one was bad, returned and replaced, now functioning.)

-6 new fuel injectors

-replaced both ECT sensors

-replaced all 6 plugs and wires, and checked for spark at coil packs

-checked fuel pressure at rail now it holds 65 constant and starts immediately

-swapped both the IAC and MAF with the ones from my '04 Level 2, no effect, and cleaned and put back in originals.

-listened for vacuum leak, sprayed around with starter fluid, nothing.

-checked seals while pulling the intake twice

-(other small things I might have forgotten while typing this)

To expand on the previous list:

-After replacing both the fuel pump and filter, we checked the pressure because it still wouldn't run. We can hear the new pump prime, and when she ran it while I monitored the gauge, it rose slowly to 65 PSI. After shutting off, it would fall. I dug into the engine, and while pulling off the intake and hoses on the front passengers side of the intake, a approx. pint of fuel fell out of the hoses and the intake itself. Several of the ports going into the heads became backed up with fuel. Leaky fuel injectors were my diagnosis. Beforehand I checked the plugs and they were pretty dirty, particularly cylinders 1,2, and 4 I believe. I tried cleaning and reinstalling the original injectors, and no luck. We ordered new injectors in the meantime. When I pulled the intake off to remove the injectors I attempted to clean, same thing, lots of fuel, so injectors must have been stuck open, bleeding off the pressure into the ports. With the new ones in, the engine primes and starts up right away without having to turn it over for 10 seconds. No leaks anywhere as far as I can tell. The entire fuel system should be good now.

Before getting to the plugs and injectors we tried the easier stuff: ECT, IAC. MAF. I replaced 1 ECT at first. After looking through my haynes, I could not find which one sent the signal to the PCM, but I found somewhere on one of these forums that is was the grey/red, and grey/xxx (I forget what color now). I replaced that one and it didn't solve it. Now that I put new injectors and everything else in, I replaced the other ECT just to eliminate any doubt that I got it wrong. Still didn't solve it.

For both the MAF and the IAC, we used the ones off my truck which runs just fine, and that didn't help at all. So I cleaned her MAF and IAC with MAF cleaner and put them back on. I also ran the engine with the MAF connected and disconnected. That didn't help.

All the seals looked fine. I checked the brake booster hose, and the elbowed hose that goes from the throttle body right behind the MAF, into the valve cover I think, because I read that hose can cause problems. I inspected the other hoses as well as I could and have not found a vacuum leak.

I still slightly suspect a vacuum leak, because before replacing the injectors, the brakes were very hard to operate 100% of the time. Now after the injectors were replaced and the engine is running a little better, the brakes work normal some of the time, but 50/50 they revert back to operating like they are manual brakes with no booster attached. At the same time though, I don't suspect a vacuum leak, because the damn this is so clean and immaculate. It was definitely garaged, it looks brand new everywhere. It makes my very decent and clean '04 Level 2 look like its been sitting in the ocean for a year.

I guess I should go over some symptoms I have encountered.

-The brake issue. They work, but are extremely stiff much of the time, previously all the time. I know what normal ranger brakes feel like.

-Still slightly rough idle. Before, it would want to die constantly and idle rough enough to jar the tensioner constantly and very bad. Now it idles much better, but still slightly rough, and still dies out coming out of gear into park or revving while in neutral and then letting it fall to idle.

-Every time I change or fix something, I take it up and down the street to see the effect. While in park before and after the injector and plug change, I would be able to get it to rev to the 3k park rev limiter. Sometimes it was harder, but it would still make it. I can do it now as well, but every time I take it out for a drive it is terribly weak. It acts like I am giving it no throttle, and sputters some too. I will be pegged to the floor, and the engine will slowly get to 2k, then 2.5k then it might act for a second like it hit a rev limiter, and drop really fast back to 2k and it just repeats this constantly.

I should add in that the street where I test from my driveway goes uphill, and I go about 200 yds before turning around in disappointment each time

! On the downhill, via our friend gravity, the engine will rev up to 3-4k, but not under its own power. What the heck is the problem and the next logical step to investigate? Now that I think about it, I haven't checked the TPS sensor I think. I'll go fiddle with it here in a moment.

! On the downhill, via our friend gravity, the engine will rev up to 3-4k, but not under its own power. What the heck is the problem and the next logical step to investigate? Now that I think about it, I haven't checked the TPS sensor I think. I'll go fiddle with it here in a moment.Overall, it has gotten better, but the issues still persist. Is this related to the timing chain rattle I can hear, or is that a separate issue like I think it is? FYI, the rattle is definitely coming from the front drivers side chain, got lucky there, so when I fix it I don't have to pull the engine.

I've been working on this for almost 4 days solid now, and could really use some help. I am no stranger to the search function, but it has only gotten me so far. Help me give this Ranger "redheaded stepchild" some new life for my little sister and her dog!

A huge thanks to any help in advance, and sorry for the extremely long post!!! I probably forgot a few things, so there is more to come possibly

.

.

#2

After engine is warmed up, unplug the IAC Valve, valve will close and idle should drop down to 500rpms, or engine may even die, either is good it means no vacuum leak.

If idle stays above 700 then you have a leak, assuming no one has messed with the "idle screw", which a fuel injection engine doesn't have, lol, that screw is for anti-diesel and TPS adjustment.

I would suggest getting a $25 vacuum gauge if you don't have one.

Good read here on tests you can do: Technical Articles: Engine testing with a Vacuum Gauge - at Greg's Engine & Machine

First get an idle vacuum reading, should be 18+ in Reno with 4.0l SOHC

If vacuum is low you should do a compression test.

4.0l SOHC has 9.7:1 ratio so should test 170+psi

remove all spark plugs for the test

push gas pedal to the floor when cranking, this shuts off fuel injectors(FYI)

Get 3 or 4 "hits" before stopping

Write down the numbers

What you are looking for is consistent pressure in all cylinders.

i.e. 165-175psi

Even 140-150 is OK as long as it is ALL cylinders

If you see that one bank is 140 and the other bank 170 then you have a slipped timing gear.

This happened to a member here, the passenger side cam has no keeper pin or key, bolt pressure holds gear in position on cam.

If it slips............rough running, and low power

Vacuum gauge can also show signs of clogged exhaust, this limits RPMs and causes general sluggishness.

Ford coil pack has an odd numbering for drivers side

3 4

2 6

1 5

Front

5 6 4 , 3.0l has same numbering, can't tell you how many times I would bet the ranch it was right...................and it wasn't, lol

Double check it and follow the wires over to the drivers side

If idle stays above 700 then you have a leak, assuming no one has messed with the "idle screw", which a fuel injection engine doesn't have, lol, that screw is for anti-diesel and TPS adjustment.

I would suggest getting a $25 vacuum gauge if you don't have one.

Good read here on tests you can do: Technical Articles: Engine testing with a Vacuum Gauge - at Greg's Engine & Machine

First get an idle vacuum reading, should be 18+ in Reno with 4.0l SOHC

If vacuum is low you should do a compression test.

4.0l SOHC has 9.7:1 ratio so should test 170+psi

remove all spark plugs for the test

push gas pedal to the floor when cranking, this shuts off fuel injectors(FYI)

Get 3 or 4 "hits" before stopping

Write down the numbers

What you are looking for is consistent pressure in all cylinders.

i.e. 165-175psi

Even 140-150 is OK as long as it is ALL cylinders

If you see that one bank is 140 and the other bank 170 then you have a slipped timing gear.

This happened to a member here, the passenger side cam has no keeper pin or key, bolt pressure holds gear in position on cam.

If it slips............rough running, and low power

Vacuum gauge can also show signs of clogged exhaust, this limits RPMs and causes general sluggishness.

Ford coil pack has an odd numbering for drivers side

3 4

2 6

1 5

Front

5 6 4 , 3.0l has same numbering, can't tell you how many times I would bet the ranch it was right...................and it wasn't, lol

Double check it and follow the wires over to the drivers side

#3

Awesome first response!

I will test the IAC how you described. I have done compression tests before, so I can run one, and I will get a vacuum gauge for both our trucks just to have, and run that test as well.

As for the weird coil pack numbering, I learned that one a long time ago on my first truck, and have paid attention to such details since!

I did not think about a clogged exhaust. I have read threads where the guys catalytic converter was totally clogged and was just plugging the entire engine. The thought hadn't crossed my mind...But it wouldn't explain why the engine is capable of revving while parked or in neutral, but not in gear.

A vacuum leak or or a slipped cam would make more sense to me. If a cam slip, it could be related to the timing chain noise? I will do some more work and report back!

I will test the IAC how you described. I have done compression tests before, so I can run one, and I will get a vacuum gauge for both our trucks just to have, and run that test as well.

As for the weird coil pack numbering, I learned that one a long time ago on my first truck, and have paid attention to such details since!

I did not think about a clogged exhaust. I have read threads where the guys catalytic converter was totally clogged and was just plugging the entire engine. The thought hadn't crossed my mind...But it wouldn't explain why the engine is capable of revving while parked or in neutral, but not in gear.

A vacuum leak or or a slipped cam would make more sense to me. If a cam slip, it could be related to the timing chain noise? I will do some more work and report back!

#4

Since this is an automatic there is also the Torque converter clutch(TCC) to consider.

This wouldn't effect idle, but shifting into gear stalling could be TCC, also when you are moving and step on the gas pedal the TCC unlocks to allow the engine to rev up and trans to down shift if needed.

This could also cause stalls when coming to a stop.

But this shouldn't limit max RPMs just make it hard to get up the RPMs with direct connection to drive line in 4th gear

Long shot

Yes vacuum gauge is one of my most used tools, second would be "The sailor's guide to colorful language".

Hold engine at 2,500RPMs and see if vacuum holds or starts to drop, indicating back pressure building up at exhaust ports.

This wouldn't effect idle, but shifting into gear stalling could be TCC, also when you are moving and step on the gas pedal the TCC unlocks to allow the engine to rev up and trans to down shift if needed.

This could also cause stalls when coming to a stop.

But this shouldn't limit max RPMs just make it hard to get up the RPMs with direct connection to drive line in 4th gear

Long shot

Yes vacuum gauge is one of my most used tools, second would be "The sailor's guide to colorful language".

Hold engine at 2,500RPMs and see if vacuum holds or starts to drop, indicating back pressure building up at exhaust ports.

Last edited by RonD; 07-10-2015 at 09:36 PM.

#5

I ran the engine warm enough to get the coolant warm, and then disconnected the IAC 2 different times. Both times the engine shut down immediately. I'm off to run some errands and will buy a vacuum gauge and compression tester, and then come back, run some tests, and maybe unhook the exhaust after the manifolds to prove/disprove a plugged exhaust.

#6

#7

I have a vacuum gauge and compression tester ordered and arriving Monday. The ones I have access to aren't here right now. I tried swapping the TPS with my ranger to see if it would help, and it didn't. one more thing eliminated.

I would think there would be a lot more problems if one of the cam's slipped, wouldn't you agree? A valve strike, blinking check engine light indicating a misfire perhaps.

I have the front of the truck on jacks right now with the exhaust manifold cup and ball joint bolts soaking in penetrating oil so I can break them and pull the exhaust away enough to see if it will free up the engine and run better. That's all I can think of doing until the gauges get here.

I would think there would be a lot more problems if one of the cam's slipped, wouldn't you agree? A valve strike, blinking check engine light indicating a misfire perhaps.

I have the front of the truck on jacks right now with the exhaust manifold cup and ball joint bolts soaking in penetrating oil so I can break them and pull the exhaust away enough to see if it will free up the engine and run better. That's all I can think of doing until the gauges get here.

#8

You can just remove the upstream O2 sensors to give exhaust relief to see if there is back pressure.

Yes, 4.0l SOHC is an interference engine but cam slip would need to be quite a few degrees for pistons and valve to meet

Fellow with that problem still had compression on the passenger bank but it was lower than drivers side, I want to say 120-130 on one bank and 170 on the other.

compression ratio for this engine is 9.7:1 so 175 would be expected across all cylinders

Yes, 4.0l SOHC is an interference engine but cam slip would need to be quite a few degrees for pistons and valve to meet

Fellow with that problem still had compression on the passenger bank but it was lower than drivers side, I want to say 120-130 on one bank and 170 on the other.

compression ratio for this engine is 9.7:1 so 175 would be expected across all cylinders

#9

Ok... I got my tools in today and did some work.

I removed the upstream O2 sensors on both sides, and no effect. It ran like crap, so I put them back in.

I took vacuum readings from 2 points on the intake manifold:

- The top rear port that leads to the brake booster,

- The drivers side port at the bottom front of the manifold that looks like it leads to a part of the ABS system.

To preface this, it was difficult to get accurate readings because the engine either wants to quickly rev up, or sputter, but rarely will it idle well.

From the brake booster port, I got 0-5 psi at a really low idle, ~12 psi when revved to 1750 rpms, ~12 when it settled for a bit at a high idle of 11-1200 rpms, and when revving it would get up to 14-15 psi max. Not looking good.

From the forward "ABS" vacuum port, I took readings with my finger on the rear brake booster port to fiddle with it. With my finger off the port, it wanted to idle at 2000 rpms and pull 12-13 psi, and when I would put my finger on the port, it would drop in rpm and start pulling 15 psi, then go about its usual behavior of rev up and die, or sputter at very low rpms, or just die.

I also tested the vacuum at the brake booster while the o2 sensors were off. Same old 12-13 psi while revving and very high idle.

I moved on to the compression test. I pulled each plug, zip-tied the throttle open, and gave approx 8 pumps of the engine with each cylinder hooked up:

Passenger side:

1= 77 psi

2= 60 psi

3= 60 psi

Drivers side:

4: 150 psi

5: 150 psi

6: 150 psi

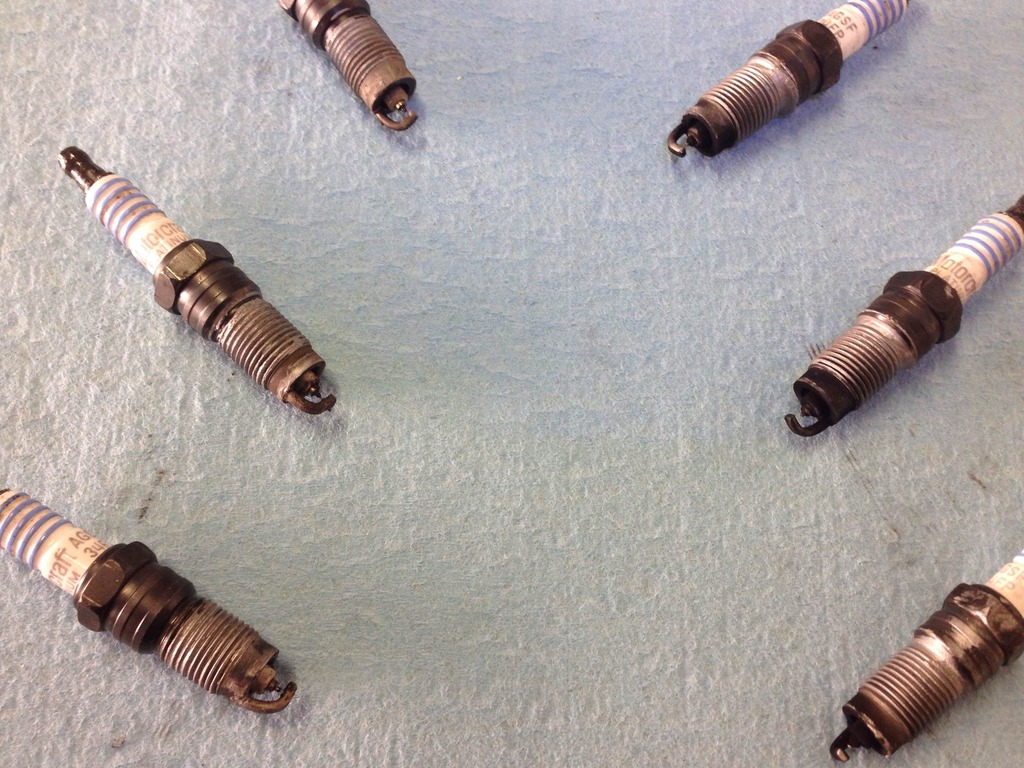

Obviously there is a problem here. I took pictures of the plugs that I am going to upload in a little, but want to get this info up first. The drivers side bank has a small coat of black carbon powder on the plugs. They have been burning, but not correctly because of bad engine operation it seems. The passengers side bank of plugs were slightly wet , but don't really show evidence of firing properly at all. I am sure they are sparking, but because of the lack of proper compression, the burn isn't correct and isn't dirty the lugs normally I think.

RonD, consistent pressures on each bank would make me think that it is the cam. Perhaps the intake valve is opening and closing late? What would my next step be? pulling off the valve covers etc., and taking a look?

I haven't dug into a SOHC before and understand there are a few special tools needed to remove the cam or the heads etc., and I do not know how to check the timing on this engine either.

As an afterthought, should I have put a brick on the gas pedal instead of zip-tying the throttle body open? Is there a sensor in the pedal that shuts off the injectors, or is that controlled by the TPS on the throttle body, in which case zip-tying would work just fine?

I removed the upstream O2 sensors on both sides, and no effect. It ran like crap, so I put them back in.

I took vacuum readings from 2 points on the intake manifold:

- The top rear port that leads to the brake booster,

- The drivers side port at the bottom front of the manifold that looks like it leads to a part of the ABS system.

To preface this, it was difficult to get accurate readings because the engine either wants to quickly rev up, or sputter, but rarely will it idle well.

From the brake booster port, I got 0-5 psi at a really low idle, ~12 psi when revved to 1750 rpms, ~12 when it settled for a bit at a high idle of 11-1200 rpms, and when revving it would get up to 14-15 psi max. Not looking good.

From the forward "ABS" vacuum port, I took readings with my finger on the rear brake booster port to fiddle with it. With my finger off the port, it wanted to idle at 2000 rpms and pull 12-13 psi, and when I would put my finger on the port, it would drop in rpm and start pulling 15 psi, then go about its usual behavior of rev up and die, or sputter at very low rpms, or just die.

I also tested the vacuum at the brake booster while the o2 sensors were off. Same old 12-13 psi while revving and very high idle.

I moved on to the compression test. I pulled each plug, zip-tied the throttle open, and gave approx 8 pumps of the engine with each cylinder hooked up:

Passenger side:

1= 77 psi

2= 60 psi

3= 60 psi

Drivers side:

4: 150 psi

5: 150 psi

6: 150 psi

Obviously there is a problem here. I took pictures of the plugs that I am going to upload in a little, but want to get this info up first. The drivers side bank has a small coat of black carbon powder on the plugs. They have been burning, but not correctly because of bad engine operation it seems. The passengers side bank of plugs were slightly wet , but don't really show evidence of firing properly at all. I am sure they are sparking, but because of the lack of proper compression, the burn isn't correct and isn't dirty the lugs normally I think.

RonD, consistent pressures on each bank would make me think that it is the cam. Perhaps the intake valve is opening and closing late? What would my next step be? pulling off the valve covers etc., and taking a look?

I haven't dug into a SOHC before and understand there are a few special tools needed to remove the cam or the heads etc., and I do not know how to check the timing on this engine either.

As an afterthought, should I have put a brick on the gas pedal instead of zip-tying the throttle body open? Is there a sensor in the pedal that shuts off the injectors, or is that controlled by the TPS on the throttle body, in which case zip-tying would work just fine?

#10

#11

We got a quote from a mechanic that is good friends with my sisters boss. He wants $6100 to replace the engine with a ford re-manufactured engine. He thinks that by the time (assuming we paid a mechanic to do it and not myself) he pulls the engine to replace the passenger timing (he would also do the drivers side) chain assembly and re-time the cam, it might just be worth replacing the entire engine, because there is also the possibility that it has gotten out of time enough to damage the intake valves or something else possibly. He wanted around $3200 to pull and fix the current engine.

I have the capability and mechanical skill to do it myself (other than the special tools required for the cam), but it would be a big project. I could either rebuild the current engine (just the cam and chain tensioners, not a full rebuild), or I can swap in a new engine as well. And I would do it wayyyyy cheaper than the mechanic.

Does anyone have any advice they can weigh in with? Who are a few reputable 4.0 SOHC engine builders/retailers? Ford wants just shy of $4000 for one, and I am not sure if they have the updated timing chain tensioners it them either.

I could call around to different wrecking yards to see if they have pulled any 4.0's with low miles, but that again is a gamble on quality and reliability. I don't want to have to go pull an engine myself at a pick n pull etc...

Other food for thought is the fact that she loves the truck, and other than the engine, the truck is truly immaculate everywhere inside and out. every bolt, inch of the frame etc... is pristine for what you would find in a used truck. The automatic tranny is a gamble, simply because I have never worked on a auto tranny before and don't know much about them. It might be perfectly fine for 200,000 miles. It was owned and driven by a grandpa...

We could really use a second or third or as many opinions as we can get to make this a positive outcome. Thanks fellas.

I have the capability and mechanical skill to do it myself (other than the special tools required for the cam), but it would be a big project. I could either rebuild the current engine (just the cam and chain tensioners, not a full rebuild), or I can swap in a new engine as well. And I would do it wayyyyy cheaper than the mechanic.

Does anyone have any advice they can weigh in with? Who are a few reputable 4.0 SOHC engine builders/retailers? Ford wants just shy of $4000 for one, and I am not sure if they have the updated timing chain tensioners it them either.

I could call around to different wrecking yards to see if they have pulled any 4.0's with low miles, but that again is a gamble on quality and reliability. I don't want to have to go pull an engine myself at a pick n pull etc...

Other food for thought is the fact that she loves the truck, and other than the engine, the truck is truly immaculate everywhere inside and out. every bolt, inch of the frame etc... is pristine for what you would find in a used truck. The automatic tranny is a gamble, simply because I have never worked on a auto tranny before and don't know much about them. It might be perfectly fine for 200,000 miles. It was owned and driven by a grandpa...

We could really use a second or third or as many opinions as we can get to make this a positive outcome. Thanks fellas.

#12

Well you really only need the Long Block 4.0l SOHC if valve piston contact is a worry for you, you have all the other parts to swap onto it.

They only made the poorly designed timing chain guides and tensioner for a few years so any rebuild will have to have the new design

There is one here for $2,250: Ford Explorer Explorer Sport Trac Mountaineer 4 0 Liter V6 SOHC Engine 2002 2007 | eBay

More parts on this one for $250 more: http://www.ebay.com/itm/NEW-REMAN-FO...-/271546016378

Look like the same company in Arizona

I would add new oil pump.

Water pump, thermostat housing are your call, swap in old or get new, they are not that hard to change if they go bad.

But you are still looking at a $5,000 bill if mechanic is charging $2,100 to R&R the engines.

They only made the poorly designed timing chain guides and tensioner for a few years so any rebuild will have to have the new design

There is one here for $2,250: Ford Explorer Explorer Sport Trac Mountaineer 4 0 Liter V6 SOHC Engine 2002 2007 | eBay

More parts on this one for $250 more: http://www.ebay.com/itm/NEW-REMAN-FO...-/271546016378

Look like the same company in Arizona

I would add new oil pump.

Water pump, thermostat housing are your call, swap in old or get new, they are not that hard to change if they go bad.

But you are still looking at a $5,000 bill if mechanic is charging $2,100 to R&R the engines.

Last edited by RonD; 07-15-2015 at 05:32 PM.

#14

Since you are concerned about valve or piston damage, I would rent a snake camera with LED light($30-$40) or you can buy USB snake cameras for under $40 to use with a laptop, they do come in handy once in awhile.

Make sure the end can fit in spark plug hole, usual smaller hole size is 13mm, spark plug end/tip is 12mm, so 10mm would be a good size

Put piston down all the way to look at the top of it.

Leak down can tell you how much rings or valves are leaking(even new engines leak), with dry and then wet test you can tell if it is the valves or rings that are leaking the most, valves, of course, would be the concern, but I would expect lower compression numbers with a bent valve, closer to 0psi

Make sure the end can fit in spark plug hole, usual smaller hole size is 13mm, spark plug end/tip is 12mm, so 10mm would be a good size

Put piston down all the way to look at the top of it.

Leak down can tell you how much rings or valves are leaking(even new engines leak), with dry and then wet test you can tell if it is the valves or rings that are leaking the most, valves, of course, would be the concern, but I would expect lower compression numbers with a bent valve, closer to 0psi

#15

#16

From 2011 but not a bad write up with pictures: Ford Explorer SOHC Timing Chain Replace

This thread has some timing tips: SOHC 4.0 general engine timing - TDC - Ford Explorer and Ranger Forums "Serious Explorations"®

This thread has some timing tips: SOHC 4.0 general engine timing - TDC - Ford Explorer and Ranger Forums "Serious Explorations"®

#17

Awesome thanks.

Since I am going this far into the engine, are there any other parts I should rebuild that would be good preventative maintenance to help it last to 200,000 or 250,000 without any major problems engine wise?

You mentioned the oil pump? I will take a look to see how small the screen is on the pickup and if it sucked anything up.

Head gaskets? Valves? Water pump? Thermostat housing (both you mentioned)? Anything that is prone to causing problems in the next 100,000 miles that is difficult to get to with the engine in that I should just replace now.

Since I am going this far into the engine, are there any other parts I should rebuild that would be good preventative maintenance to help it last to 200,000 or 250,000 without any major problems engine wise?

You mentioned the oil pump? I will take a look to see how small the screen is on the pickup and if it sucked anything up.

Head gaskets? Valves? Water pump? Thermostat housing (both you mentioned)? Anything that is prone to causing problems in the next 100,000 miles that is difficult to get to with the engine in that I should just replace now.

#18

Wow...I totally forgot to post on my findings for the problem, since there will definitely be people visiting this thread from their google searches.

I ended up pulling the engine and re-doing all the timing and replacing tensioners and cleaning out bits in the pan and pump.....Basically, the entire passenger bank was not operating. The rear jackshaft bolt that clamps the passenger lower chain sprocket snapped in two, the the chain wasn't spinning, hence the passenger cam wasn't rotating. The engine was half dead. After replacing and reinstalling the engine, it runs beautifully! While it was out, I replaced head gaskets, cleaned the tops of the pistons and the chambers, and replaced every gasket on the way out.

I ended up pulling the engine and re-doing all the timing and replacing tensioners and cleaning out bits in the pan and pump.....Basically, the entire passenger bank was not operating. The rear jackshaft bolt that clamps the passenger lower chain sprocket snapped in two, the the chain wasn't spinning, hence the passenger cam wasn't rotating. The engine was half dead. After replacing and reinstalling the engine, it runs beautifully! While it was out, I replaced head gaskets, cleaned the tops of the pistons and the chambers, and replaced every gasket on the way out.

#19

#20

Before reinstalling the engine, I turned it by hand, and didn't feel any contact within it. No noises either. It is possible and likely that when the bolt broke, the cam settled into a position in which none of the valves were open enough to strike the piston. It would take incredible luck I would think for it to balance itself and come to a stop with a valve out far enough for a strike. Just a guess based on 6 springs resisting motion of the cam to any point with a fully open valve. We haven't had any problems yet.

I could run a compression check at the next fluid and plug change to see how it is doing.

I could run a compression check at the next fluid and plug change to see how it is doing.

#21

Yes, that would be possible, and yes very good luck, go buy a lotto ticket :)

You can do a compression test but if you don't notice a lack of power then no real reason to, outside of a baseline test for future use.

I do compression test on all vehicles when I get them, just so if I do have a problem down the road I have a baseline to compare current test to.

You can do a compression test but if you don't notice a lack of power then no real reason to, outside of a baseline test for future use.

I do compression test on all vehicles when I get them, just so if I do have a problem down the road I have a baseline to compare current test to.

Thread

Thread Starter

Forum

Replies

Last Post

ChargerOnDavins

2.9L & 3.0L V6 Tech

4

10-12-2023 03:37 PM

Lemonpicker

SOHC - 2.3L & 2.5L Lima Engines

15

08-31-2009 02:14 PM