How-To: Rear Axle and Pinion Seal Replacement (7.5 ring gear)

#1

How-To: Rear Axle and Pinion Seal Replacement (7.5 ring gear)

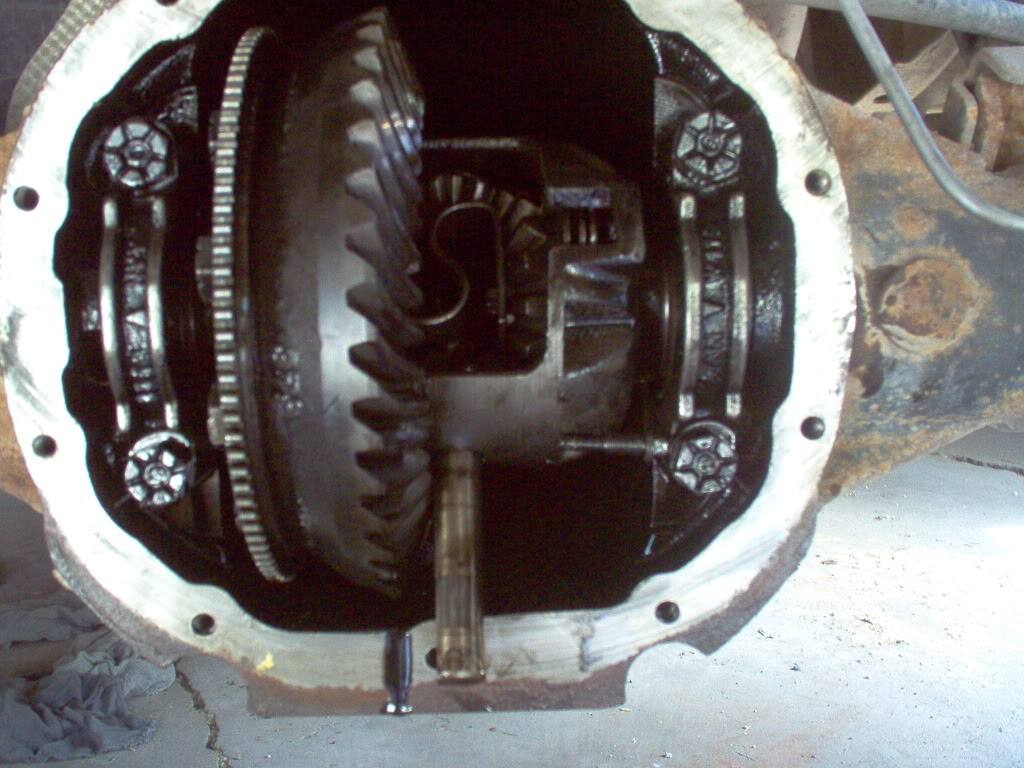

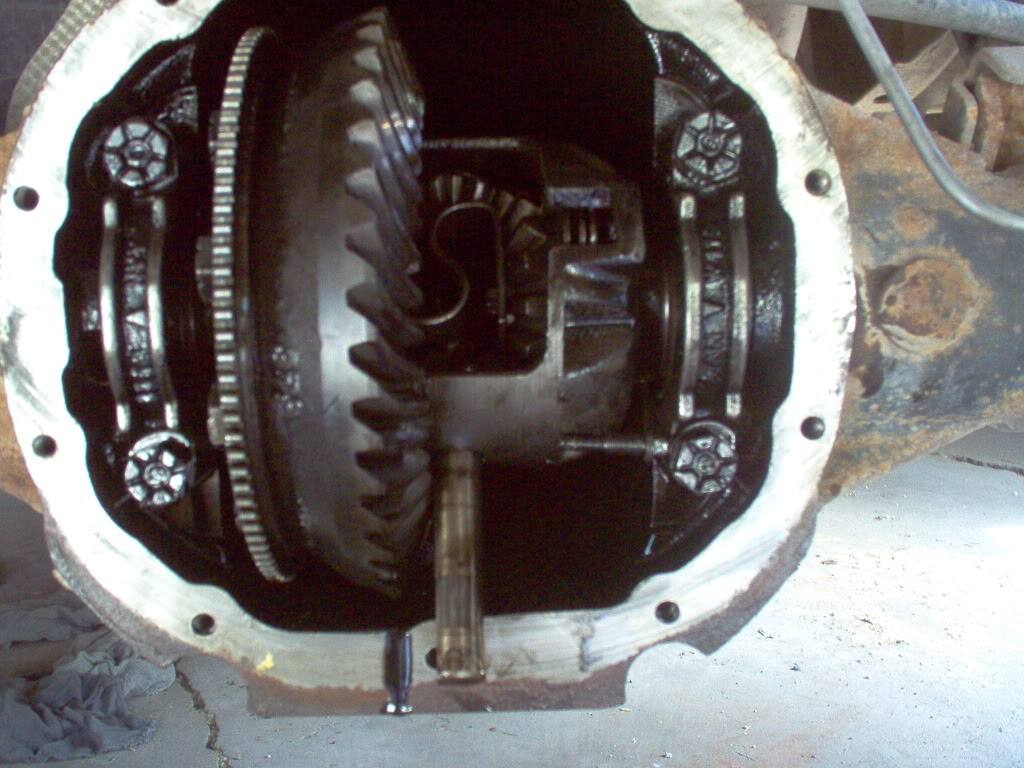

Hey all, I recently replaced all the seals in the rear end of my ranger. I thought I would throw up this how to as I had some issues that don't apply to the 8.8 ring gears.

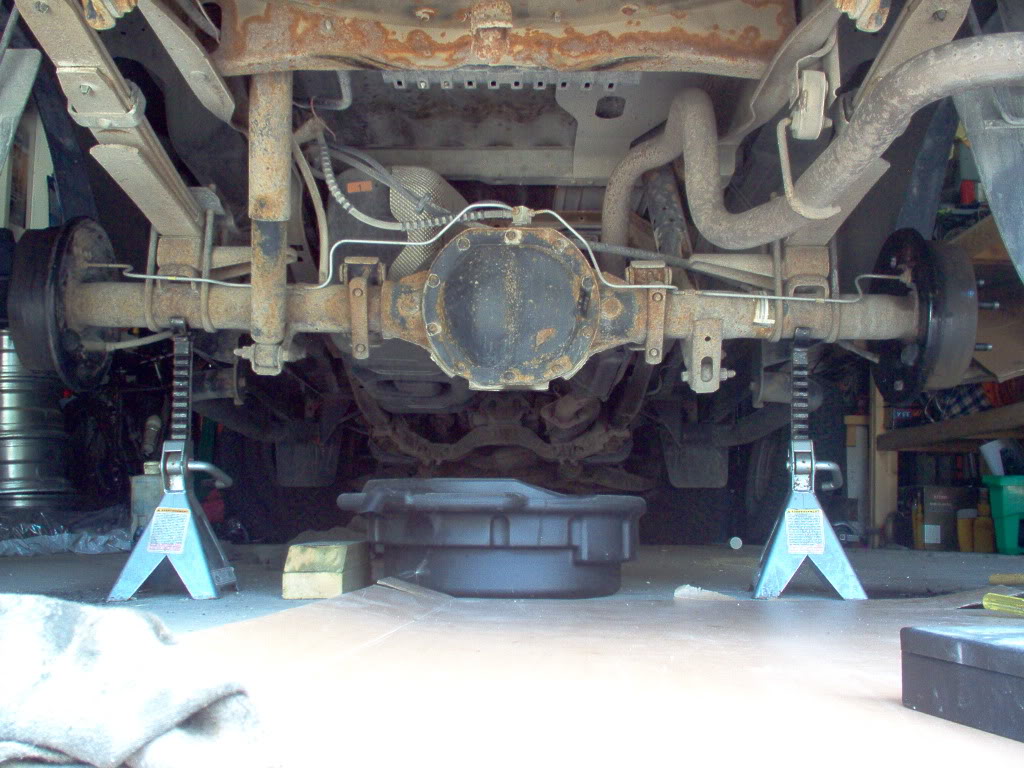

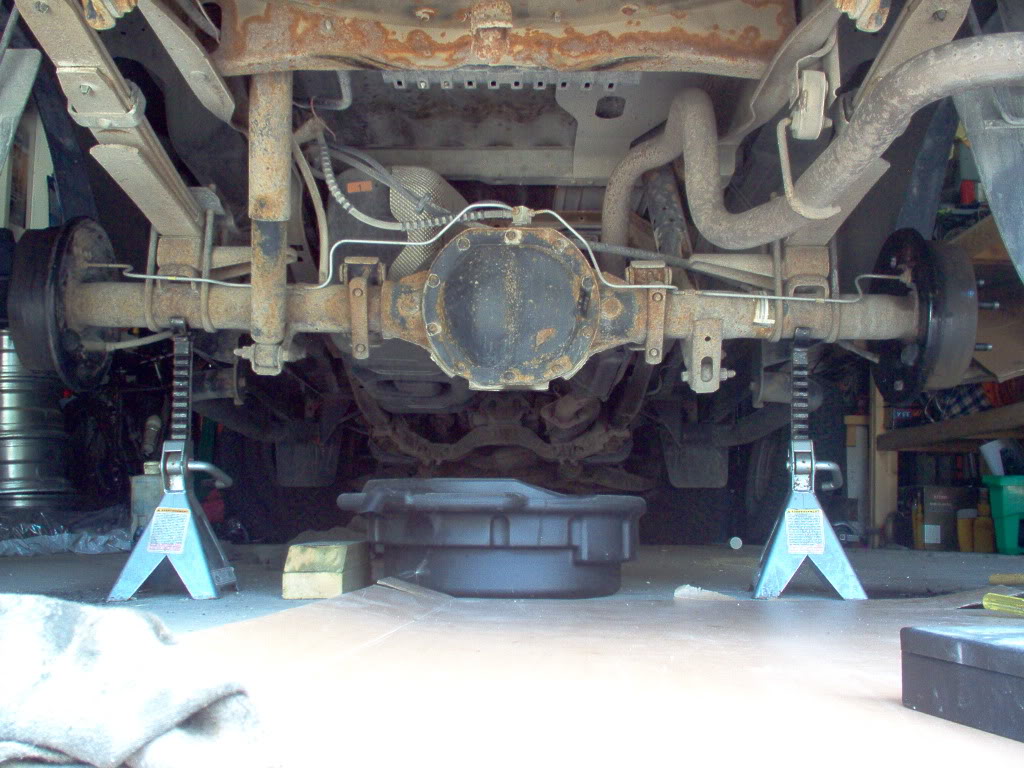

First loosen the lugs on the rear tires and raise the rear end putting it on axle stands, making sure to block at least one front wheel.

Lower the sparetire to give your self some extra room, remove the rear tires and brake drums.

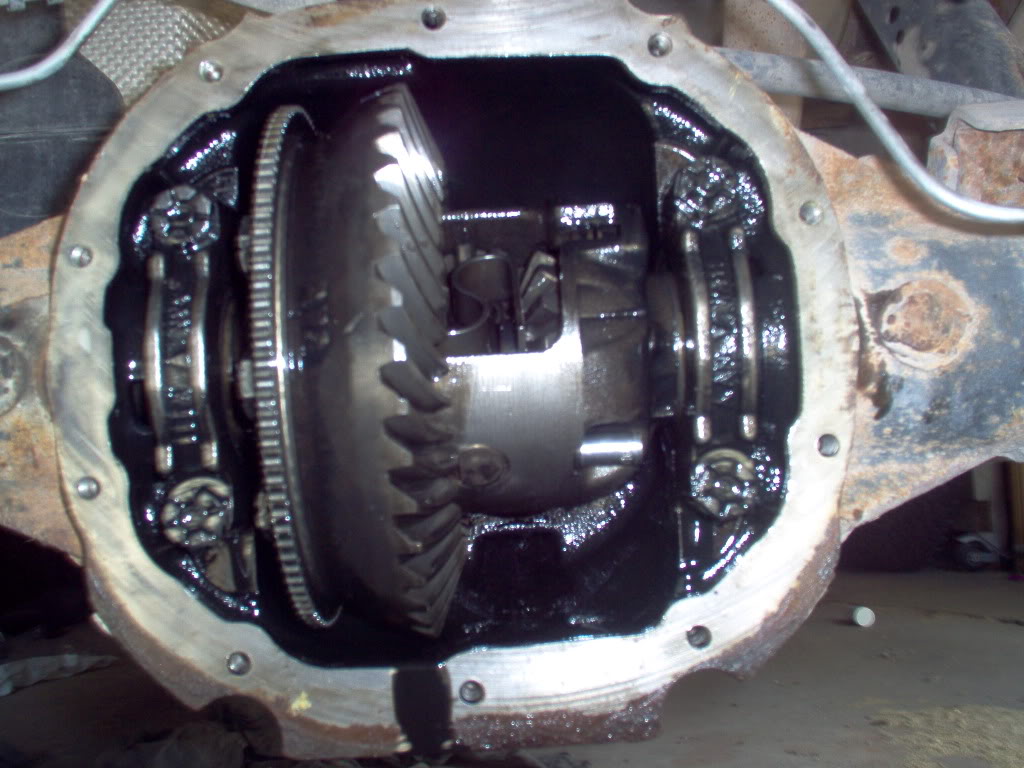

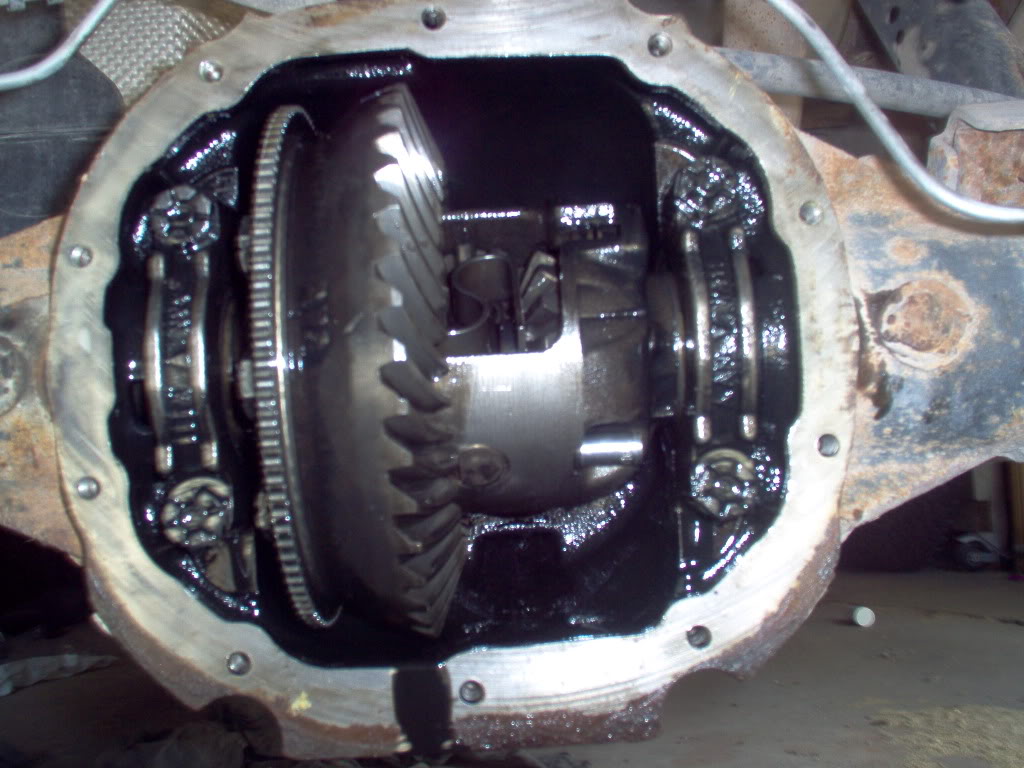

Remove all but the top two bolts of the differential, the two top bolts undo about half way. Use a putty knife or some other tool that wont mar the surface of the diff, (I wouldn't recommend a screwdriver if you have other options) allow the diff fluid to drain into a pan.

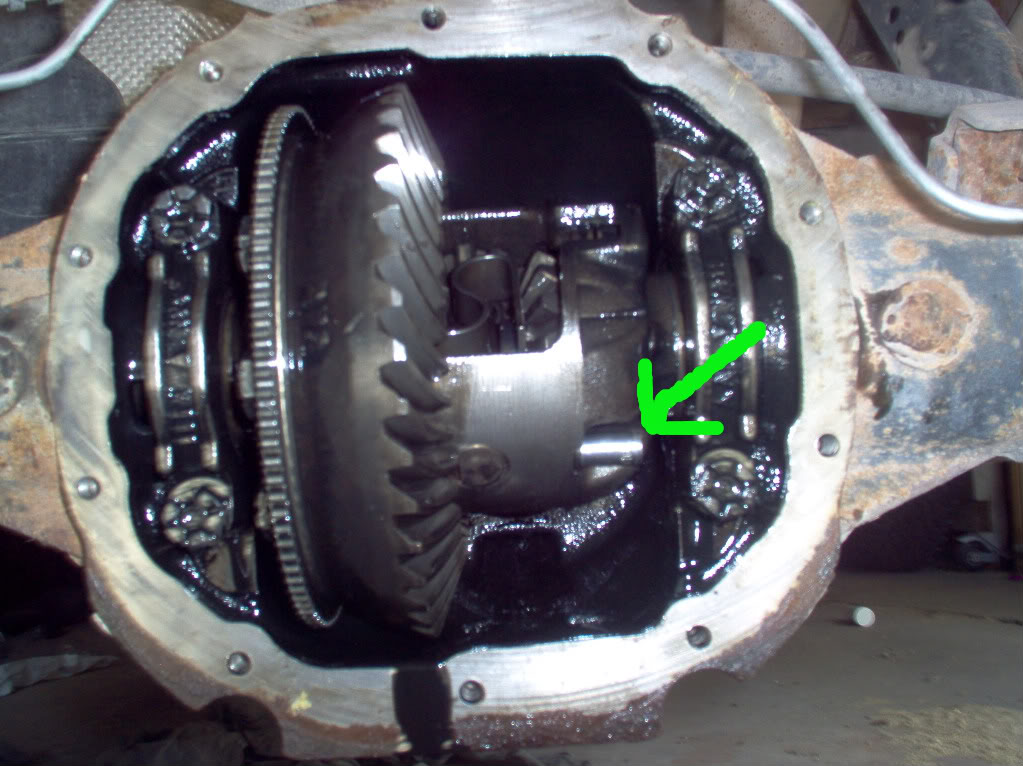

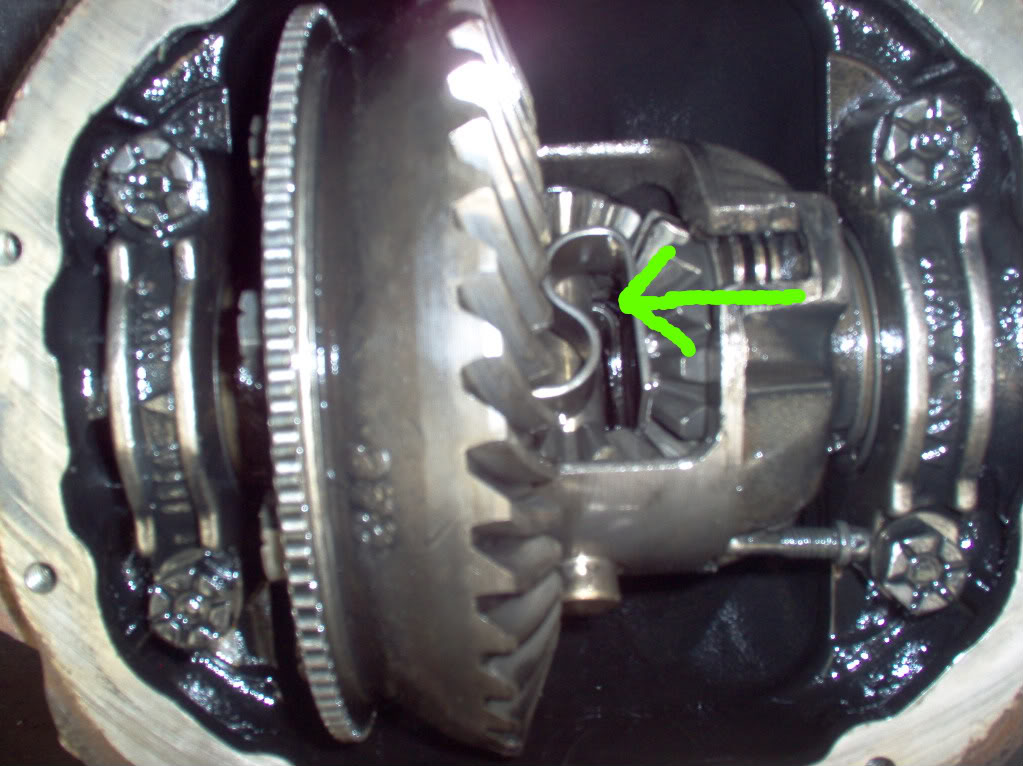

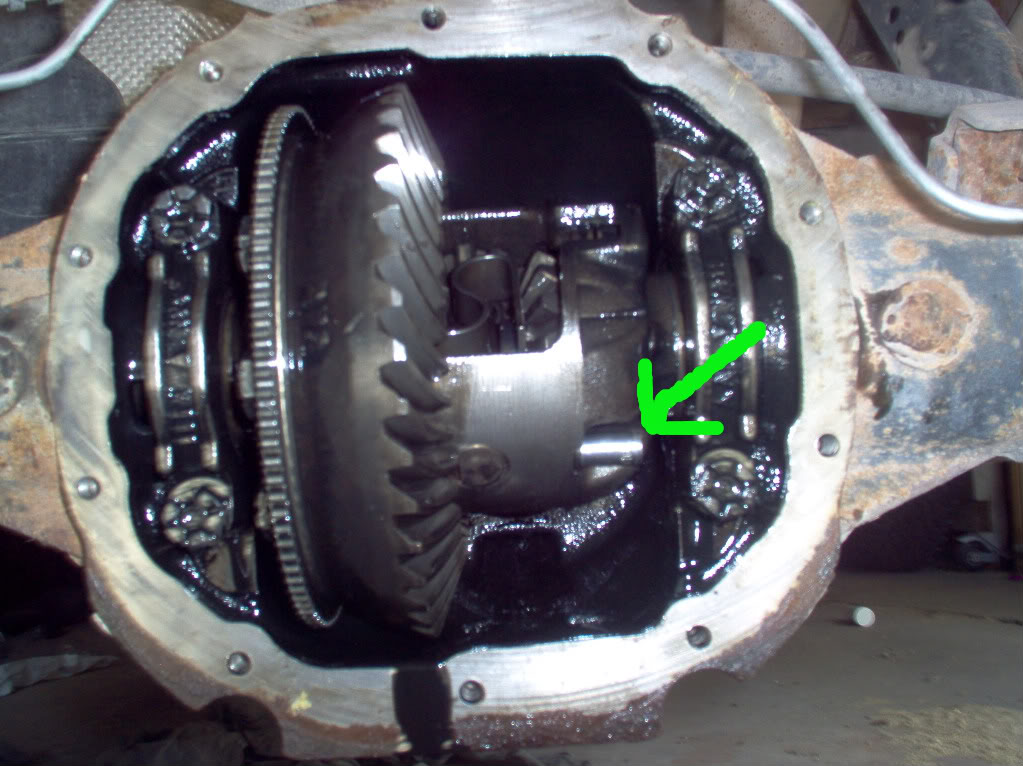

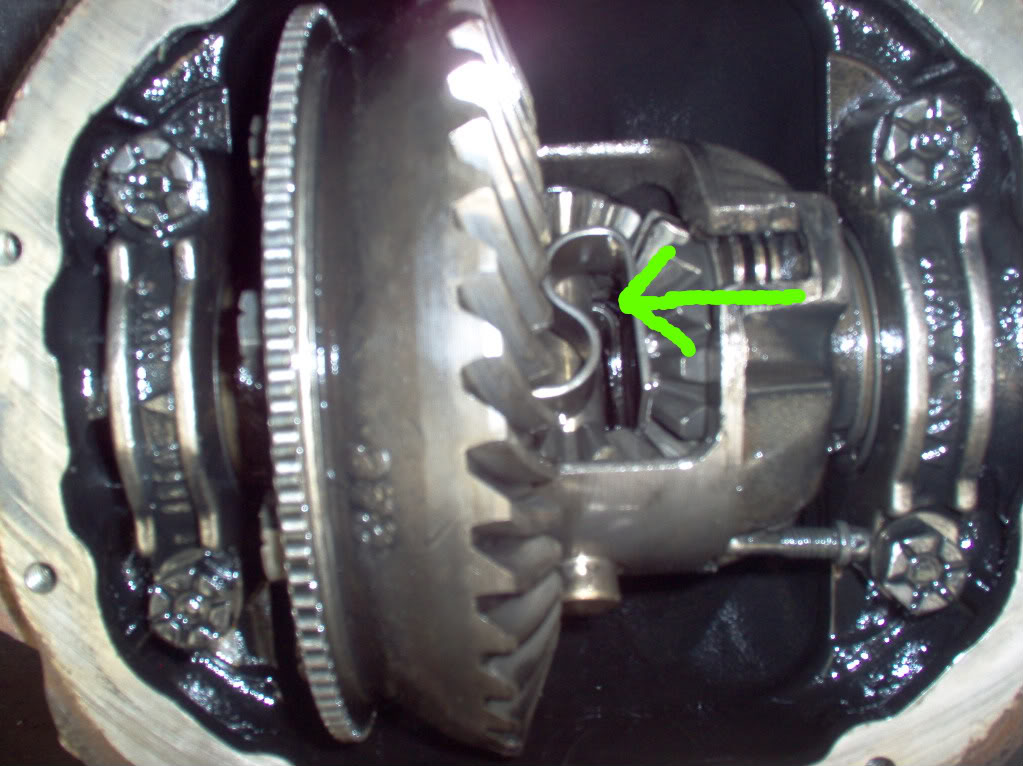

Put the truck in neutral and rotate the ring gear so the the retaining bolt and the pinion shaft are in the a postion that it can be loosened. Put the truck back in park or gear so that the gear will not move once shaft is removed (THIS IS CRITICAL DON"T FORGET THIS).

Using a 5/16th socket, undo the retaining bolt. Once it is loose use your fingers to back it out until it clears the pinion shaft. There is not enough remove to completely remove it on a 7.5 ring.

Once the bolt is loose the pinion shaft should come out with a little pressure.

bring the pinion shaft down far enough to clear the axle shafts, The shaft will not clear the ring gear but it will allow room to move the axle shafts.

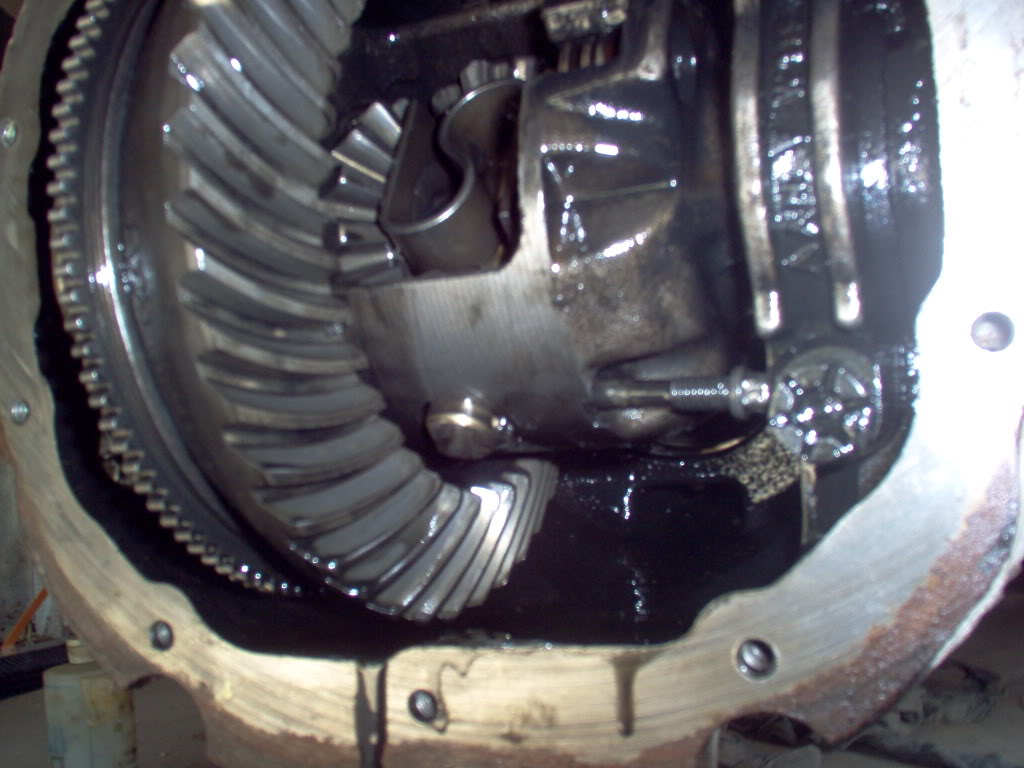

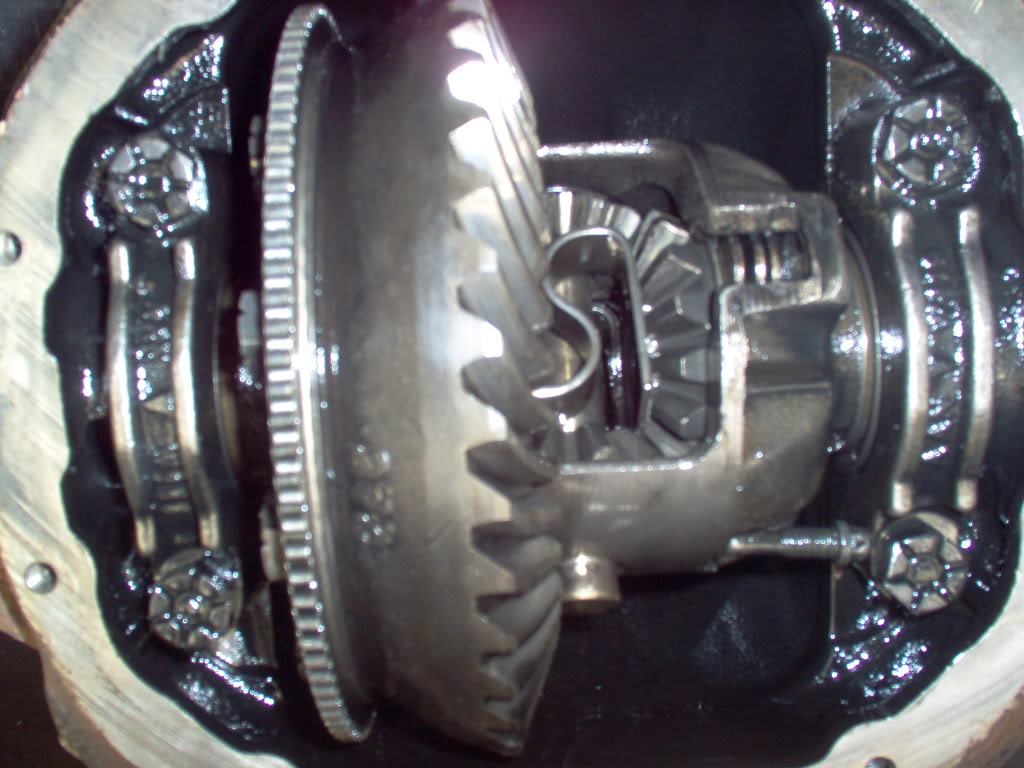

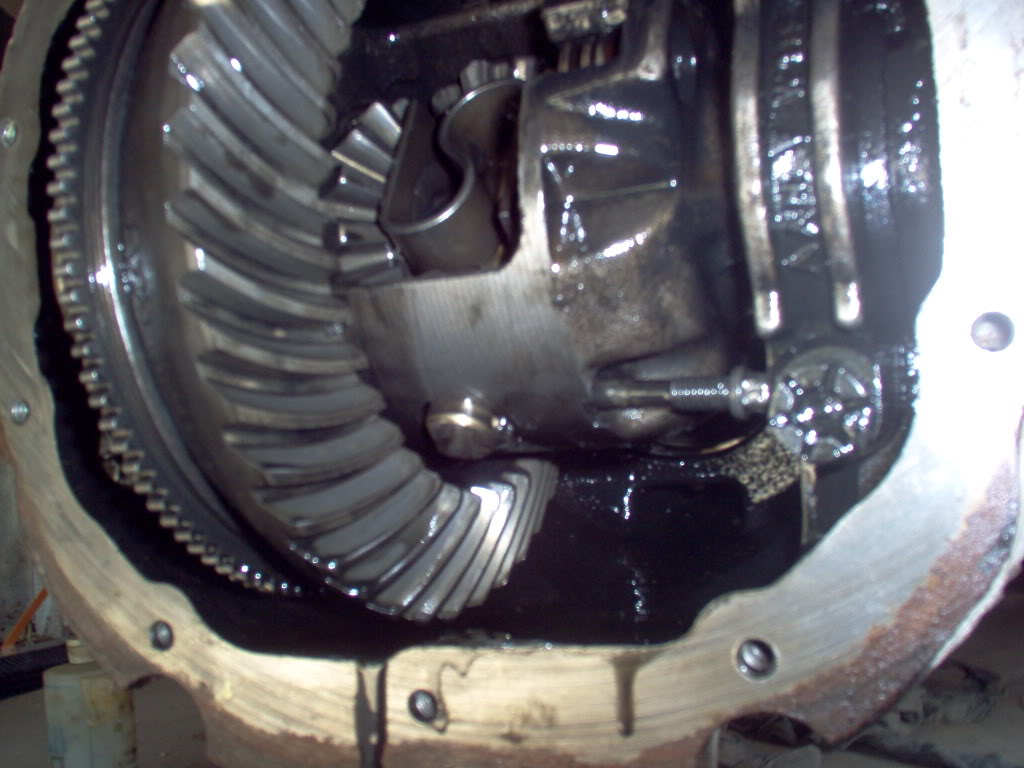

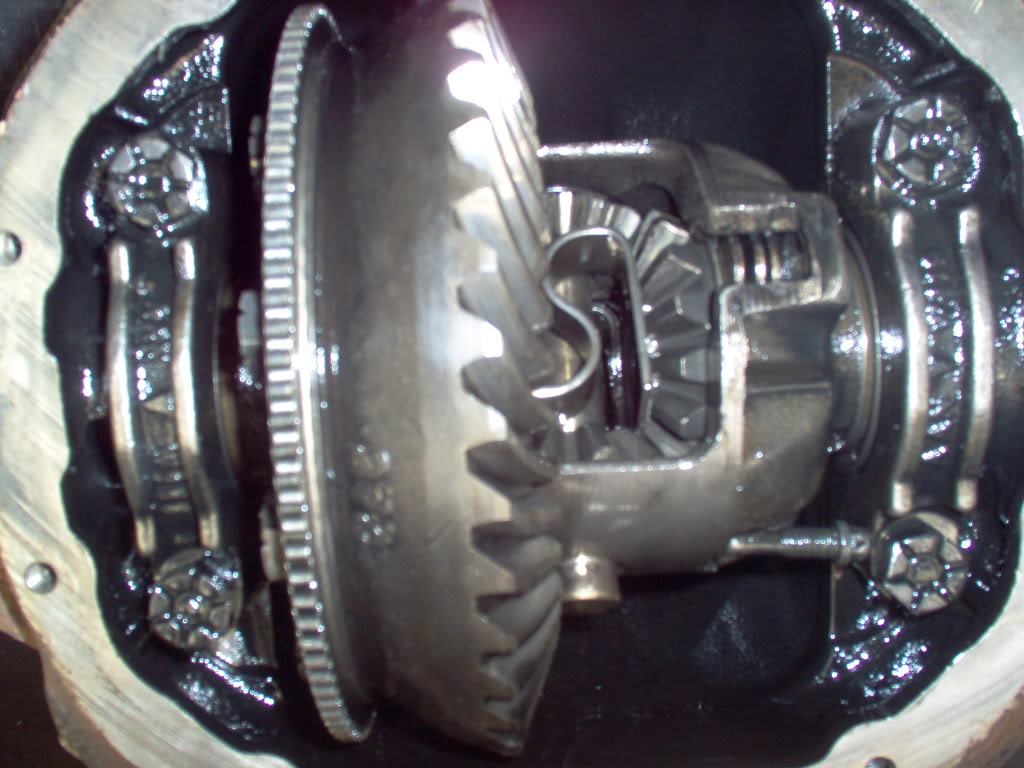

The axle shafts can now be pushed in allowing access to the retaining c-clips. The c-clips can be removed using pair of needle nose pliers or just pushed off with your fingers and remove from the bottom of the diff.

Remove the axle shafts and now the axle seals can be removed using a seal puller or flat screwdriver ( Make sure to pry on the seals and not on the bearings).

The new seals can now be installed using a bearing installer or a socket large enough to fit the case only of the seal. Gently tap the seal into place until it is flush with the axle housing. Since you are in there already give your axle bearings a light repacking of grease.

You can now push the pinion shaft back in for the moment so that nothing will move.

You can now re-install the axle shafts gently rotating it until it goes through the splines, with both axles in now remove the pinion shaft again so the c-clips can be re-installed. The clips can be pushed back on with your fingers. Once the c-clips are on gently pull back on the axle shafts to reseat them. The pinion shaft and retaining bolts can be re-installed.

If your axle seals were leaking I would replace the brake shoes at this time. Also be sure to clean your brake drums very well with brake cleaner, having them reground wouldn't hurt either. My drums had a big gouge in them so I just replaced them. Put your tires back on and lower the truck back down.

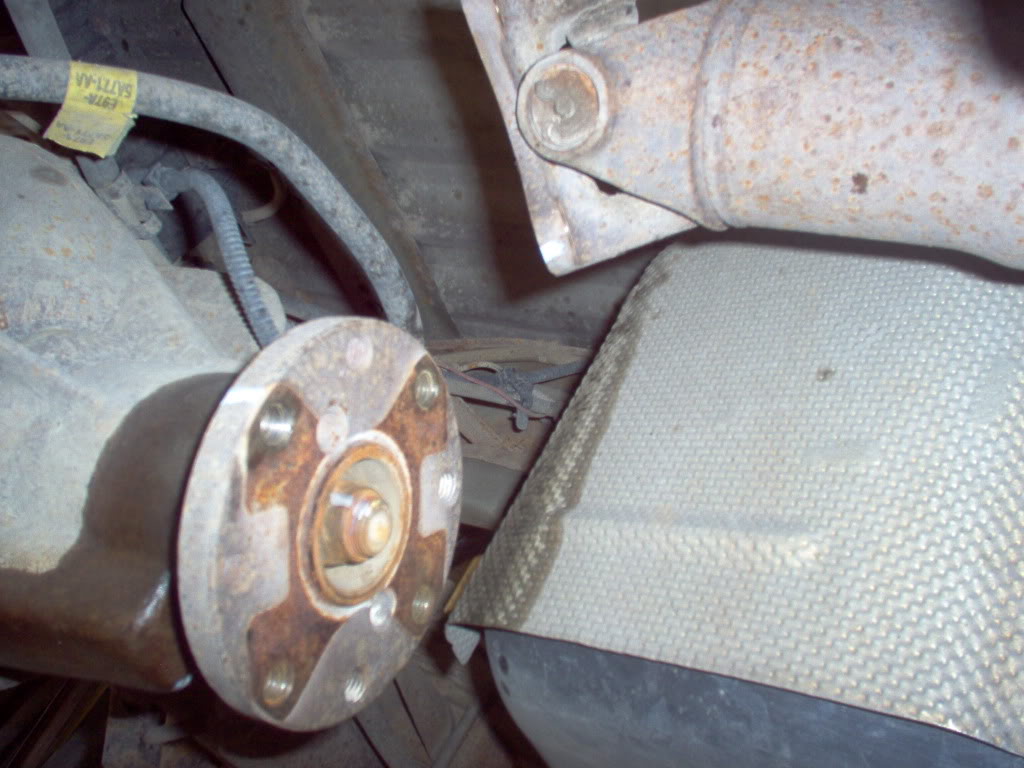

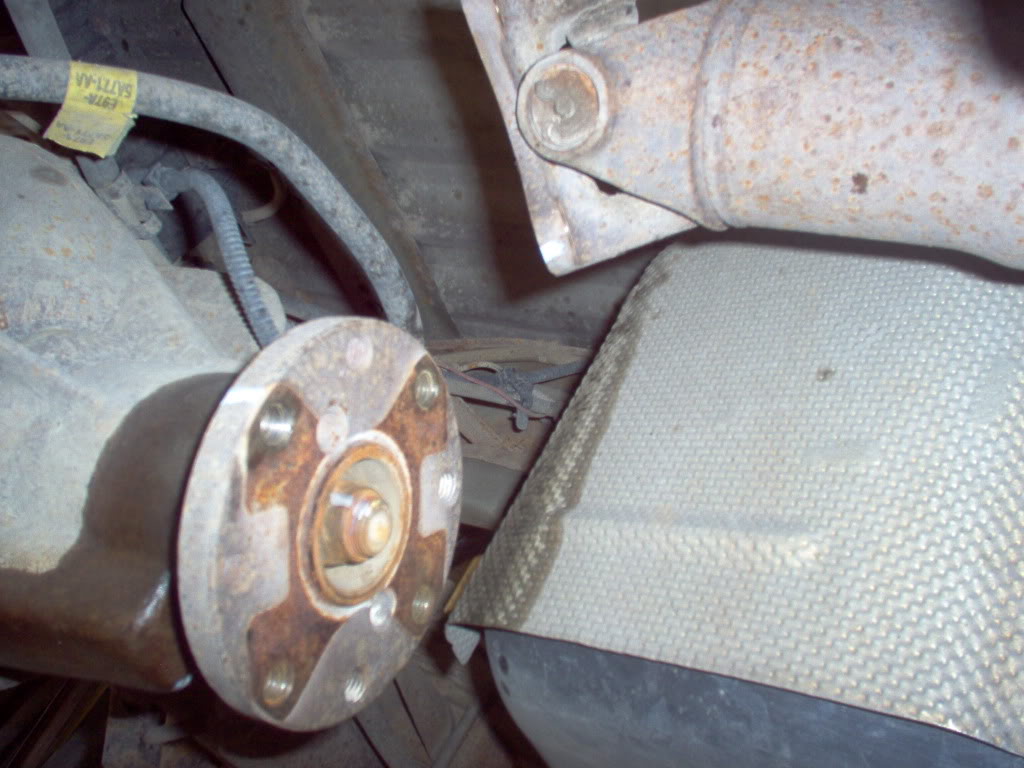

Axle seals are now done, and on to the pinion seal. Mark the axle flange and the pinion flange with a paint marker so they can be realigned properly later.

Mark the pinion flange and axle housing to line them up later. Tie up the axle shaft so it is out of your way. Mark the orientation of the pinion nut and pinion shaft.

Using a depth guage measure the depth of the pinion shaft protruding from the pinion nut (mine measured at 5 mm). Using a 1 1/16th socket remove the pinion nut and gently tap the pinion flange. With the pinion flange removed check the condition of the crush sleeve replace if neccessary. Remove the old seal with a seal puller.

Install the new seal, gently tap it back into place until it is fully seated. Reinstall the pinion flange making sure all marks line up. Tighten the pinion nut until the marks are lined up at the depth you measured earlier. Reinstall the axle flange to the pinion flange lining up the marks.

Now its a good time to give the diff cover a shot of paint. I cleaned the housing very well, I gave it a light sanding and shot it with two coats of spray on bedliner.

For ****s and giggles I tossed on a summit sticker I had laying around.

Once everything is dry its time reinstall the diff cover. Using black RTV silicone gasket maker apply a thin layer of gasket material over the entire mating surface of the diff cover, apply a 1/4" bead all the way around the insides of the boltholes.

Reinstall the diff cover installing the bolts finger tight in an alternating pattern. Allow the gasket to setup for about 1/2 an hour but no longer than an hour. Tighten the gasket down in an alternating pattern making sure not to overtighten the bolts as that may warp the diff cover. I also touched up the axle tag with the paint marker.

Allow the gasket to setup for a little while longer then you can refill the diff. the fill hole is on the drivers side just below the flange, it can be removed with a 3/8th ratchet extention. The 7.5 axle takes about 2.25 liters to fill.

You are now done and I would recoomend tossing whatever clothes you were wearing and the diff fluid stinks and the smell doesn't come out easy, so don't wear anything you want to keep.

First loosen the lugs on the rear tires and raise the rear end putting it on axle stands, making sure to block at least one front wheel.

Lower the sparetire to give your self some extra room, remove the rear tires and brake drums.

Remove all but the top two bolts of the differential, the two top bolts undo about half way. Use a putty knife or some other tool that wont mar the surface of the diff, (I wouldn't recommend a screwdriver if you have other options) allow the diff fluid to drain into a pan.

Put the truck in neutral and rotate the ring gear so the the retaining bolt and the pinion shaft are in the a postion that it can be loosened. Put the truck back in park or gear so that the gear will not move once shaft is removed (THIS IS CRITICAL DON"T FORGET THIS).

Using a 5/16th socket, undo the retaining bolt. Once it is loose use your fingers to back it out until it clears the pinion shaft. There is not enough remove to completely remove it on a 7.5 ring.

Once the bolt is loose the pinion shaft should come out with a little pressure.

bring the pinion shaft down far enough to clear the axle shafts, The shaft will not clear the ring gear but it will allow room to move the axle shafts.

The axle shafts can now be pushed in allowing access to the retaining c-clips. The c-clips can be removed using pair of needle nose pliers or just pushed off with your fingers and remove from the bottom of the diff.

Remove the axle shafts and now the axle seals can be removed using a seal puller or flat screwdriver ( Make sure to pry on the seals and not on the bearings).

The new seals can now be installed using a bearing installer or a socket large enough to fit the case only of the seal. Gently tap the seal into place until it is flush with the axle housing. Since you are in there already give your axle bearings a light repacking of grease.

You can now push the pinion shaft back in for the moment so that nothing will move.

You can now re-install the axle shafts gently rotating it until it goes through the splines, with both axles in now remove the pinion shaft again so the c-clips can be re-installed. The clips can be pushed back on with your fingers. Once the c-clips are on gently pull back on the axle shafts to reseat them. The pinion shaft and retaining bolts can be re-installed.

If your axle seals were leaking I would replace the brake shoes at this time. Also be sure to clean your brake drums very well with brake cleaner, having them reground wouldn't hurt either. My drums had a big gouge in them so I just replaced them. Put your tires back on and lower the truck back down.

Axle seals are now done, and on to the pinion seal. Mark the axle flange and the pinion flange with a paint marker so they can be realigned properly later.

Mark the pinion flange and axle housing to line them up later. Tie up the axle shaft so it is out of your way. Mark the orientation of the pinion nut and pinion shaft.

Using a depth guage measure the depth of the pinion shaft protruding from the pinion nut (mine measured at 5 mm). Using a 1 1/16th socket remove the pinion nut and gently tap the pinion flange. With the pinion flange removed check the condition of the crush sleeve replace if neccessary. Remove the old seal with a seal puller.

Install the new seal, gently tap it back into place until it is fully seated. Reinstall the pinion flange making sure all marks line up. Tighten the pinion nut until the marks are lined up at the depth you measured earlier. Reinstall the axle flange to the pinion flange lining up the marks.

Now its a good time to give the diff cover a shot of paint. I cleaned the housing very well, I gave it a light sanding and shot it with two coats of spray on bedliner.

For ****s and giggles I tossed on a summit sticker I had laying around.

Once everything is dry its time reinstall the diff cover. Using black RTV silicone gasket maker apply a thin layer of gasket material over the entire mating surface of the diff cover, apply a 1/4" bead all the way around the insides of the boltholes.

Reinstall the diff cover installing the bolts finger tight in an alternating pattern. Allow the gasket to setup for about 1/2 an hour but no longer than an hour. Tighten the gasket down in an alternating pattern making sure not to overtighten the bolts as that may warp the diff cover. I also touched up the axle tag with the paint marker.

Allow the gasket to setup for a little while longer then you can refill the diff. the fill hole is on the drivers side just below the flange, it can be removed with a 3/8th ratchet extention. The 7.5 axle takes about 2.25 liters to fill.

You are now done and I would recoomend tossing whatever clothes you were wearing and the diff fluid stinks and the smell doesn't come out easy, so don't wear anything you want to keep.

#2

Join Date: Jan 2005

Location: West Topsham, VT

Posts: 1,709

Likes: 0

Received 0 Likes

on

0 Posts

"check the condition of the crush sleeve"....yeah, once it's crushed it's done, there is no "condition".

You really should use a new crush sleeve, new nut, and reset the pinion bearing preload when you do this. That's a little more involved process than just marking and spinning the nut back on. You can usually get it back close to spec, but if you don't you can ruin a rear end real quick! I know, I've done it!

Good write up, just trying to add some important steps/info.

You really should use a new crush sleeve, new nut, and reset the pinion bearing preload when you do this. That's a little more involved process than just marking and spinning the nut back on. You can usually get it back close to spec, but if you don't you can ruin a rear end real quick! I know, I've done it!

Good write up, just trying to add some important steps/info.

Last edited by buckgnarly; 08-20-2010 at 09:30 AM.

#3

yeah I'm sure there are steps I missed.

That what I meant with the crush sleeve.

I appreciate the extra info, I went into this fix with limited knowledge and since there was only write ups on the 8.8. I was real nervous about the pinion. Ive tested the truck out awith few good loads and so far so good no problems.

That what I meant with the crush sleeve.

I appreciate the extra info, I went into this fix with limited knowledge and since there was only write ups on the 8.8. I was real nervous about the pinion. Ive tested the truck out awith few good loads and so far so good no problems.

#4

#5

Thread

Thread Starter

Forum

Replies

Last Post

Splash96

OLD - Engine & Drivetrain

0

06-26-2012 06:49 PM

Splash96

OLD - Engine & Drivetrain

2

06-26-2012 06:47 PM