Toolbox Tray Replacement

#1

Toolbox Tray Replacement

So one morning I opened my toolbox and noticed the plastic tray that hold all my screw drivers and combo wrenches was cracked and hanging down. So I decided to start a new project in class, to give me something to do.

I had only hand plasma cut aluminum once before, and figured making a new tray that way would take too long with filing and sanding to look good. So I plugged in my tray frame into CAD and made it 2in wider than the tray that was in there and about 1/2in deeper. Then put a chamfer on the front of it to compensate for the lock and rod mechanism on the front of the toolbox on the inside. After I did that, I fully welded the whole inside and sanded it down. What do you guys think?

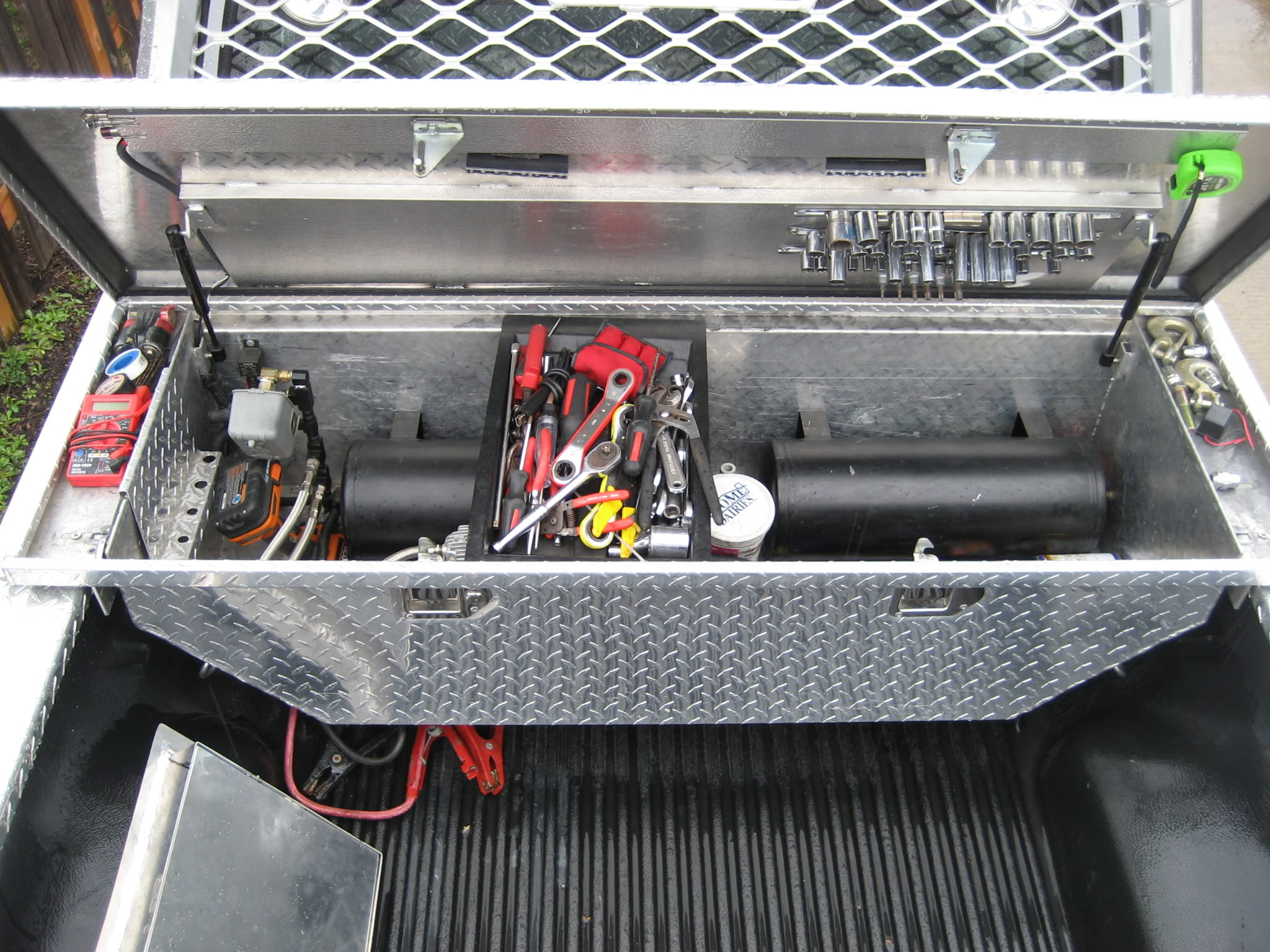

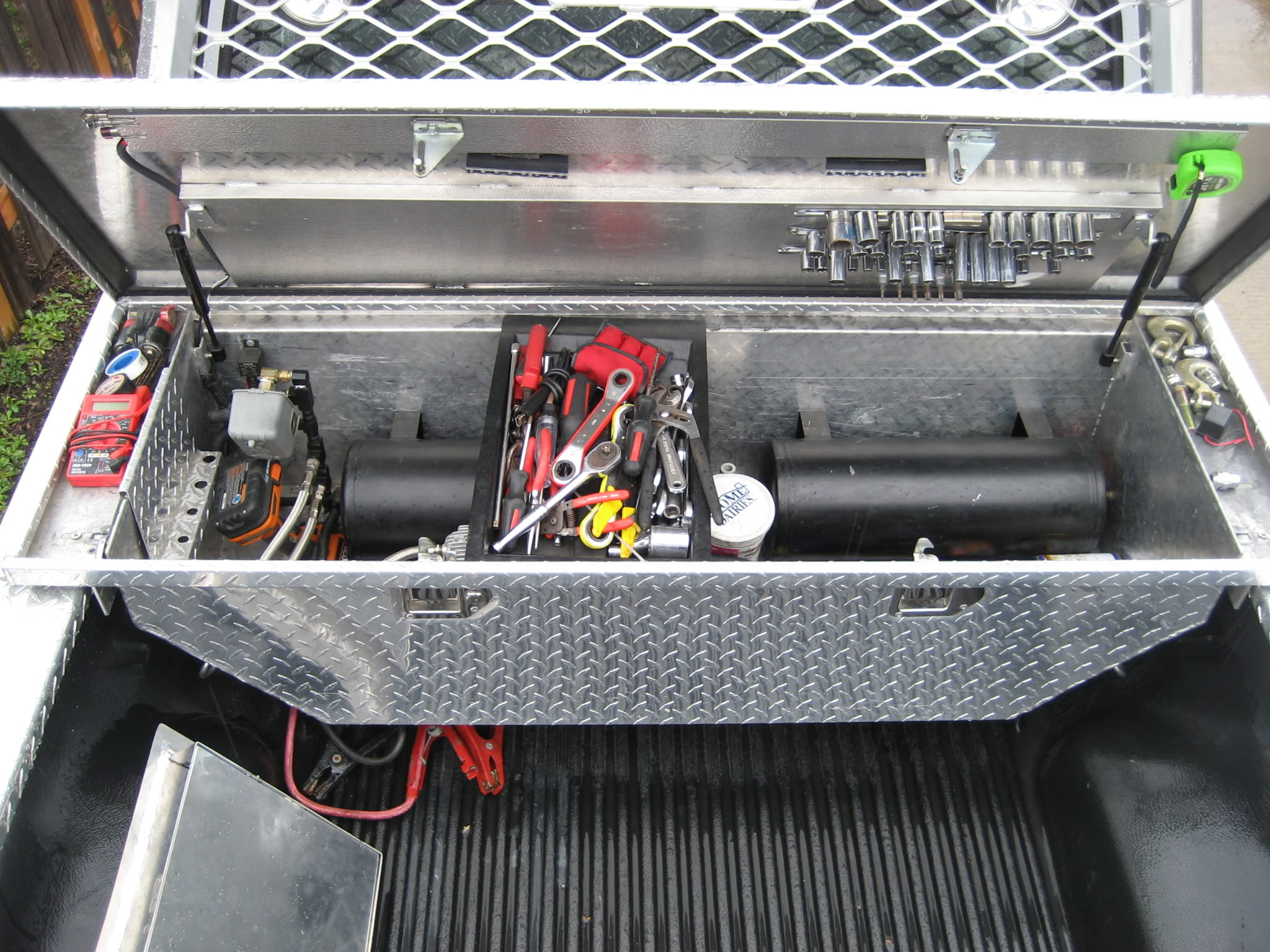

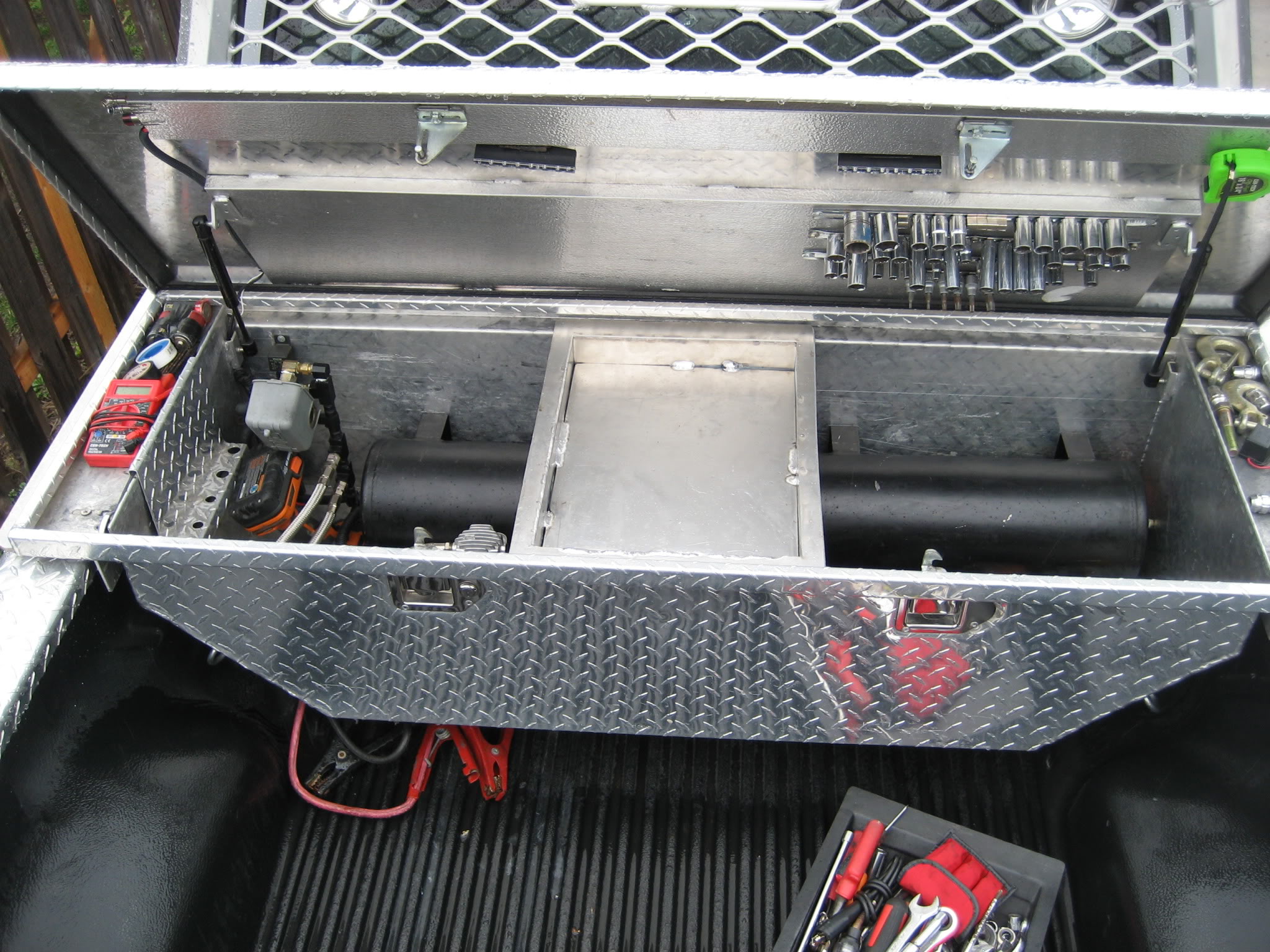

Before:

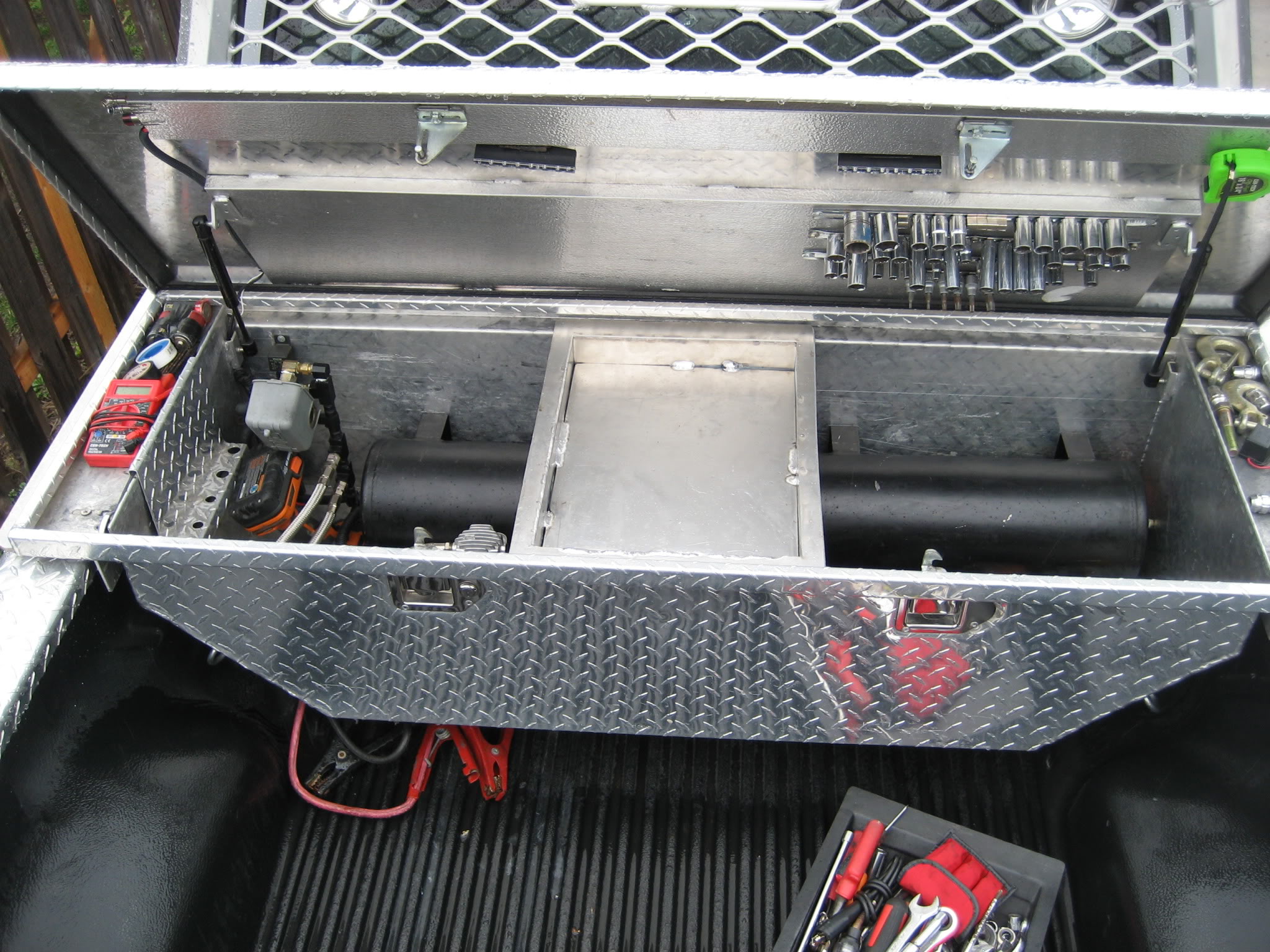

Middle point:

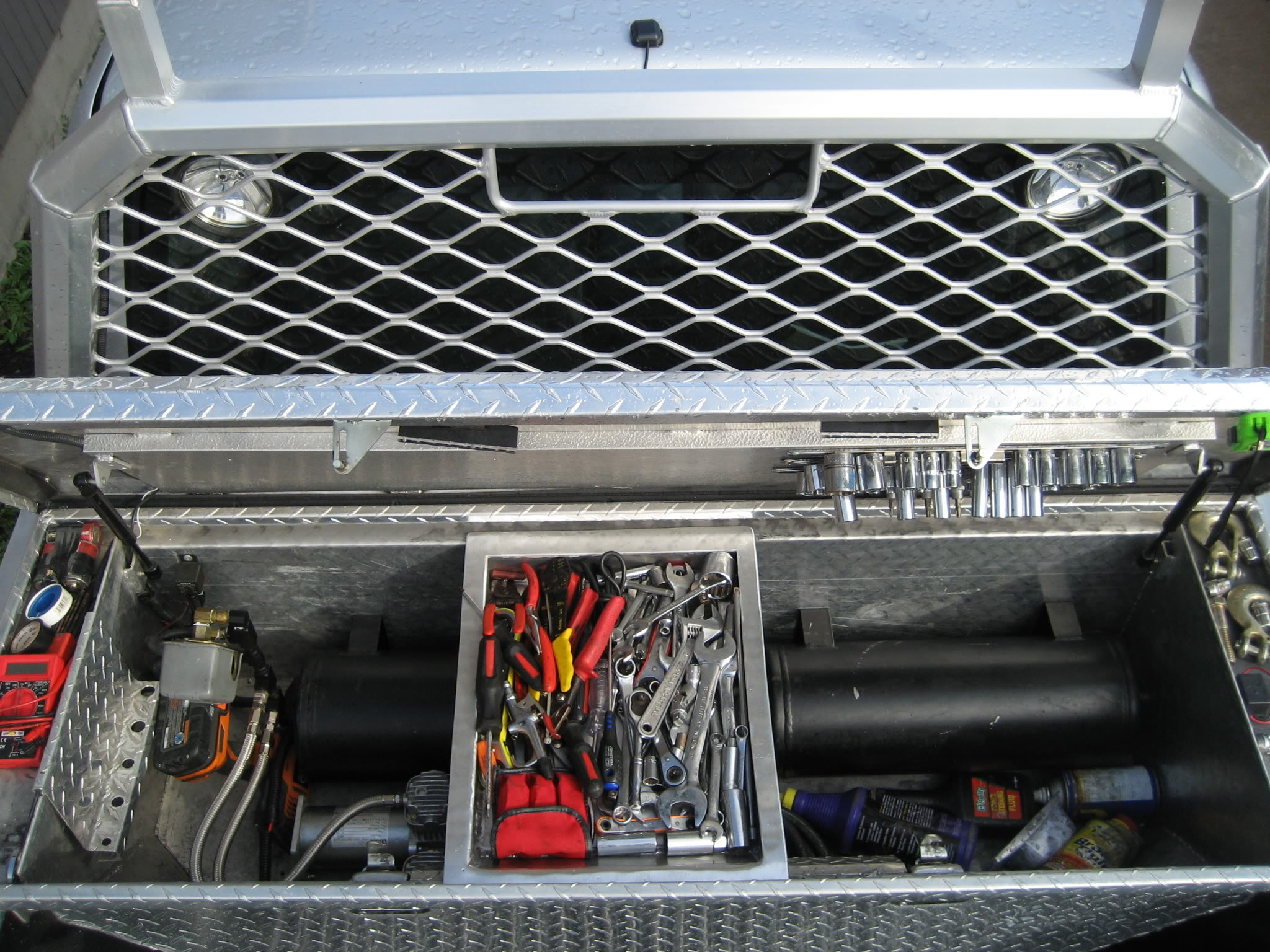

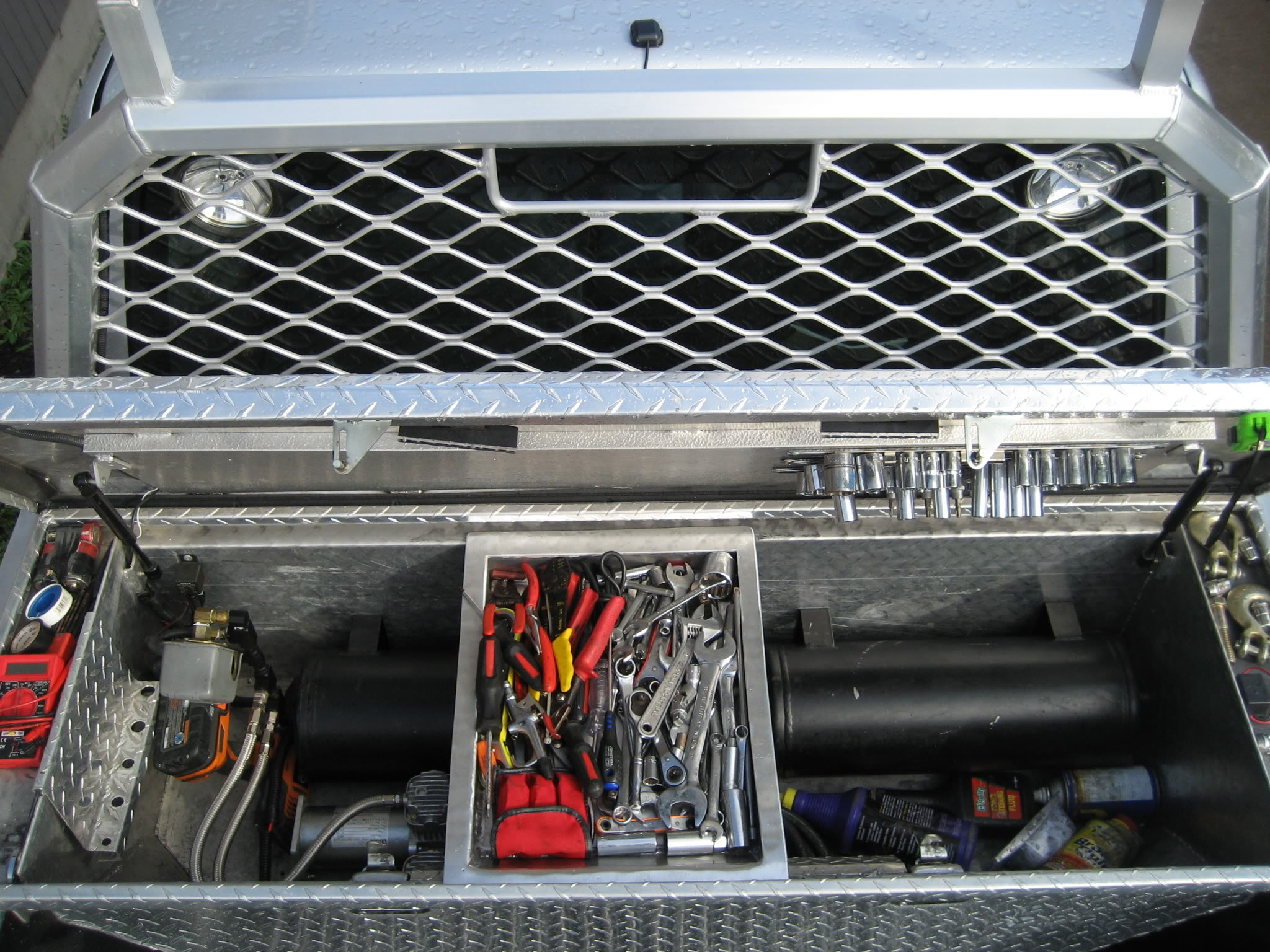

After:

What do you guys think?

And our hookah base busted, so I made a new one. Old school GLASS Crystal Srpings water jug. Holds 4 gallons of smoke!

I had only hand plasma cut aluminum once before, and figured making a new tray that way would take too long with filing and sanding to look good. So I plugged in my tray frame into CAD and made it 2in wider than the tray that was in there and about 1/2in deeper. Then put a chamfer on the front of it to compensate for the lock and rod mechanism on the front of the toolbox on the inside. After I did that, I fully welded the whole inside and sanded it down. What do you guys think?

Before:

Middle point:

After:

What do you guys think?

And our hookah base busted, so I made a new one. Old school GLASS Crystal Srpings water jug. Holds 4 gallons of smoke!

#3

#5

#8

#9

I don't know what I'm gonna do when I'm done with school and don't have driving distance access to the shop (15mins from my house right now). Unless I can get myself into a shop back home as a TIG welder. Only thing I'm not certified in is alum, but I sure can weld it. It's almost impossible to cert on alum.

Yup! Had to do something about it.

It really is!

They're almost like a spring. You push them on the rail and the thing flexes for the socket to go around it then it springs back. IDK, they just stay there.

#13

#14

man my little items....like screwdrivers, pliers, and other little stuff somehow find a way to hop over a 4inch wall and squeeze through the small gap between it and the lid when i wheel.....i could never keep those in there....u should make some sort of tether between the tray and the sides that way u can pull it to either side when u need to and u dont have to get in ur truck to get ur tools...that would be sick..

#15

to expand on my question,

what is the make and model of the compressors (looks like you run two)

CFM and pressure output.

recovery time and tank capacity

amp draw

how quick can you air up a 33 from 15 to 30 psi?

are you happy with this setup, what would you change?

#18

do you actually know anything in detail about his onboard air setup? perhaps you could give some specific answers.

#19

quite apparently i could already tell that he had the compressor, tanks and related hardware, so i fail to see why you even bothered with your initial response.

do you actually know anything in detail about his onboard air setup? perhaps you could give some specific answers.

do you actually know anything in detail about his onboard air setup? perhaps you could give some specific answers.

Basically, it is just small mini-truckers set up, powering a horn and having a output for "on board air."

hope that helps, guy.

#20

Yeah mang, i've seen it it person. He has two 5-gallon tanks (10-gallons of air total). A Viair 380 compressor if i remember right. It takes like 5 minutes for it to fully filly the tanks up to 150psi. Just run a 30Amp relay to control the compressor and an according pressure switch (which turns on and off the compressor according to the pressure inside the tank).

Basically, it is just small mini-truckers set up, powering a horn and having a output for "on board air."

hope that helps, guy.

Basically, it is just small mini-truckers set up, powering a horn and having a output for "on board air."

hope that helps, guy.

The specs are actually two 3 gallon 200psi air tanks connected at the ends with a "T" fitting and a quick disconnect to run my 25ft 1/2" air line with tire inflator on it, two ViAir 380c (16a/comp) 100% duty cycle (100% at 100psi and 55% at 200psi) compressors running 1/2" hard line tubing and compression fittings, 1/4" hard line tubing to the 200psi 7-color LED pressure gauge, and a 200psi adjustable pressure switch that's set at 195psi off and 150psi on. I'm using a 40a relay on a 40a mega fuse and holder using 10-12g wiring. This is all mainly to power my Nathan P3 Locomotive horn :)

Is that specific enough? lol

#22

and put other stuff in the tray.

I normally carried my spare axles/hubs and the tools I needed to change them, the rest of my tools I left at camp.

#23

#25