time to flame the welding noob...

#27

Exactly, and it's different with every machine. The best thing you can do is keep playing with the settings and your technique until you get satisfactory welds.

#30

I agree with Zaebeard. Most people I run into run too cold and they are afraid to turn the heat up. The dime looking welds will come eventually, what you should start practicing is welding two pieces of metal together to ensure good penetration.

Most people worry to much about the surface of their welds and don't pay enough attention to penetration which IMO is what counts.

Most people worry to much about the surface of their welds and don't pay enough attention to penetration which IMO is what counts.

#31

Another good tip is to watch the weld puddle behind the arc, not the actual arc itself. It's tough, because the arc is just sooooo pretty! But pay attention to how your puddle is moving, how long or short it is, and that will help you lay good beads with good penetration. Also get practicing on your out-of-position welds. i.e. up and down, overhead, etc. Those are the ones you're going to need while working on your truck!

As for the lincoln vs. miller vs. hobart debate... I think it's a bunch of hoo-ha. You've got a lincoln, so there's no real reason to step up to a big expensive machine until you know you're going to need it. Get used to using your welder now, and keep an eye out for a gas regulator and try to get a gas set up. My Lincoln 140 welds everything I need it to great, and I don't need to go hunting around for a 220v outlet. If you've got your own garage and are going to be building a tube chassis or something like that, then a 220 would be best, but for now, learn to use what you've got!

As for the lincoln vs. miller vs. hobart debate... I think it's a bunch of hoo-ha. You've got a lincoln, so there's no real reason to step up to a big expensive machine until you know you're going to need it. Get used to using your welder now, and keep an eye out for a gas regulator and try to get a gas set up. My Lincoln 140 welds everything I need it to great, and I don't need to go hunting around for a 220v outlet. If you've got your own garage and are going to be building a tube chassis or something like that, then a 220 would be best, but for now, learn to use what you've got!

#32

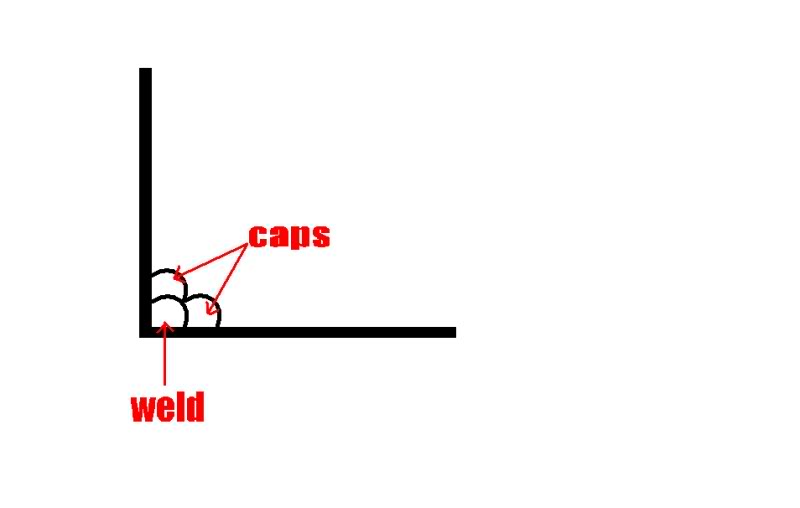

. take two pieces of 1/4" plate, about 3" x 5" and work on welding them together at 90 degree angles. and then you can also cap them if you want for extra practice.

. take two pieces of 1/4" plate, about 3" x 5" and work on welding them together at 90 degree angles. and then you can also cap them if you want for extra practice.

#33

Join Date: Sep 2008

Location: Sumter, SC

Posts: 633

Likes: 0

Received 0 Likes

on

0 Posts

#35

Join Date: Sep 2008

Location: Sumter, SC

Posts: 633

Likes: 0

Received 0 Likes

on

0 Posts

#36

Something I like to do to check penetration as practice is to weld tubing together then cut right by the weld with a chopsaw to check the pentration of the weld. Of course you can't always cut everything to check for penetration but it does allow you to become more comfortable with welding in a hotter setting.

#40

Depending on what you're welding though, warping is BAD! It's hard to come up with a "benchmark" to base whether you're getting good penetration or not in every instance. You just need to practice and check yourself until you can look at the weld and you'll know whether it's good or not. Keep at it!

#42

i have this old rod welder and i can lay beads like no ones business your not doin to bad at all imo i remember my first weld it was more a a blob hahaha but ya go weld somethings together just got to a scrapyard and get a bunch of steel grind ya some rust free spots on it and practice ( or weld lawnmowers together (what i did i took 3 yard sale lawnmowers and welded the base's together flipped the motors on the outer 2 connected all the throtle cables and power wheel cables to the single middle handle and put yamaha 10hp outboard carbs on them it was totaly worth it now i can cut acres of lawn in no time ) that was totaly off subject but anywho just to goofy things first like that befor takeing it to your truck

Thread

Thread Starter

Forum

Replies

Last Post

FMD

General Technical & Electrical

4

12-08-2005 04:41 PM

INT3RC3PTOR

General Technical & Electrical

8

10-10-2005 05:56 PM