Welding Cart Project - Now complete, pics on page 5!

#1

Welding Cart Project - Now complete, pics on page 5!

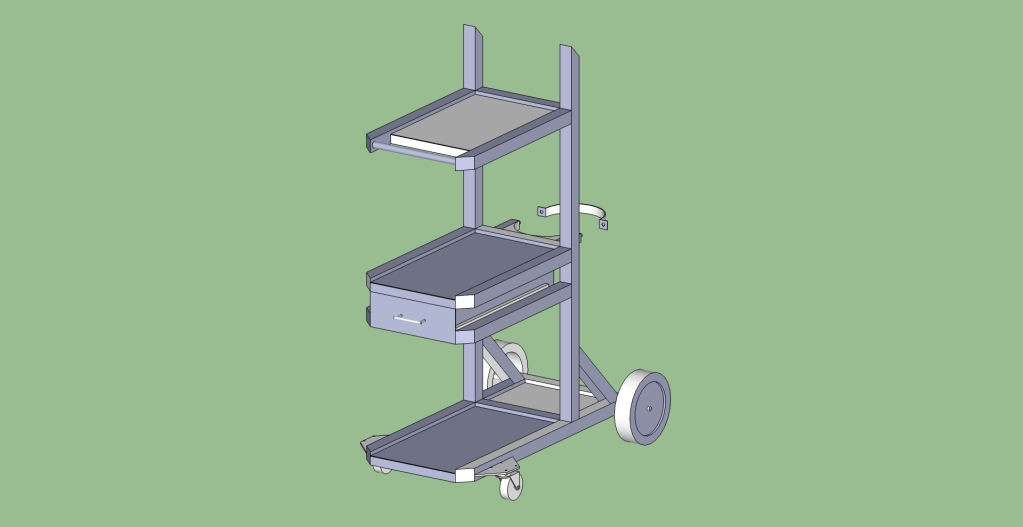

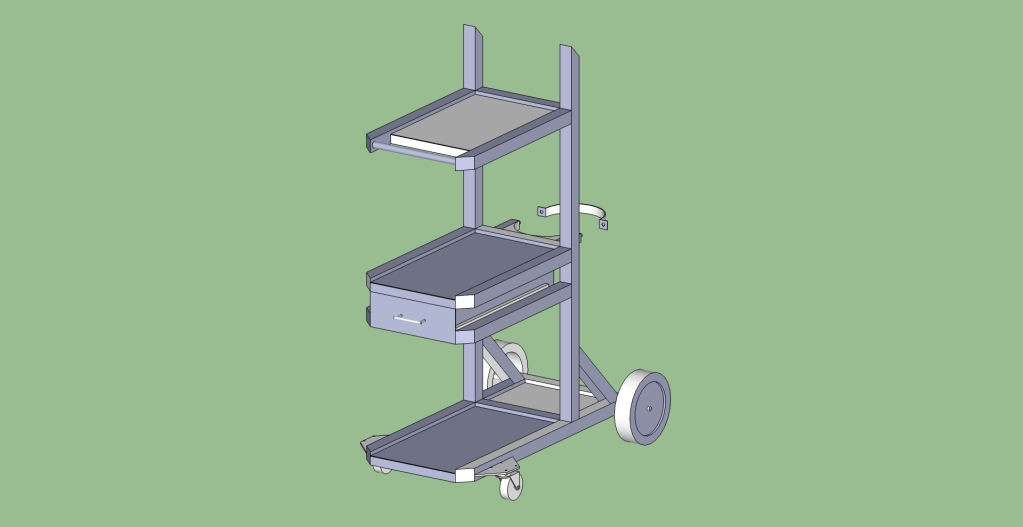

A while back I made a thread looking for cart ideas... so I figured I'd post up what I've been working on. I got the idea for the basic design of this off the Hobart Forums but I changed pretty much everything else.

I wanted to make something that would hold my plasma cutter, as well as my 110v and 220v welders while keeping the footprint as small as possible!

I don't really have any mid-build pictures but it's nearly done... just mostly the small stuff to do.

Drew it up on Google Sketchup:

I didn't have any lighter stuff to make the drawer out of... this one's pretty beefy. The drawer is 10x20" and weighs 16lbs! lol

Threw the machines on there to see how it's going to look:

I have to clean up a few welds in order to get the bottom shelf done, then make the holder for the bottle as well as all the hangers for the cables and cords.

Let me know what you think, and post up any ideas for keeping all the cords in order!

I wanted to make something that would hold my plasma cutter, as well as my 110v and 220v welders while keeping the footprint as small as possible!

I don't really have any mid-build pictures but it's nearly done... just mostly the small stuff to do.

Drew it up on Google Sketchup:

I didn't have any lighter stuff to make the drawer out of... this one's pretty beefy. The drawer is 10x20" and weighs 16lbs! lol

Threw the machines on there to see how it's going to look:

I have to clean up a few welds in order to get the bottom shelf done, then make the holder for the bottle as well as all the hangers for the cables and cords.

Let me know what you think, and post up any ideas for keeping all the cords in order!

#3

Thanks!

There is only going to be one bottle, when the one I have is empty I'm going to exchange for a bigger one.

I'm going to box in that square section between the rear wheels and then if you look at the first pic I posted you can see there's sort of a clamp that is welded to the back of the uprights to hold the top of the tank.

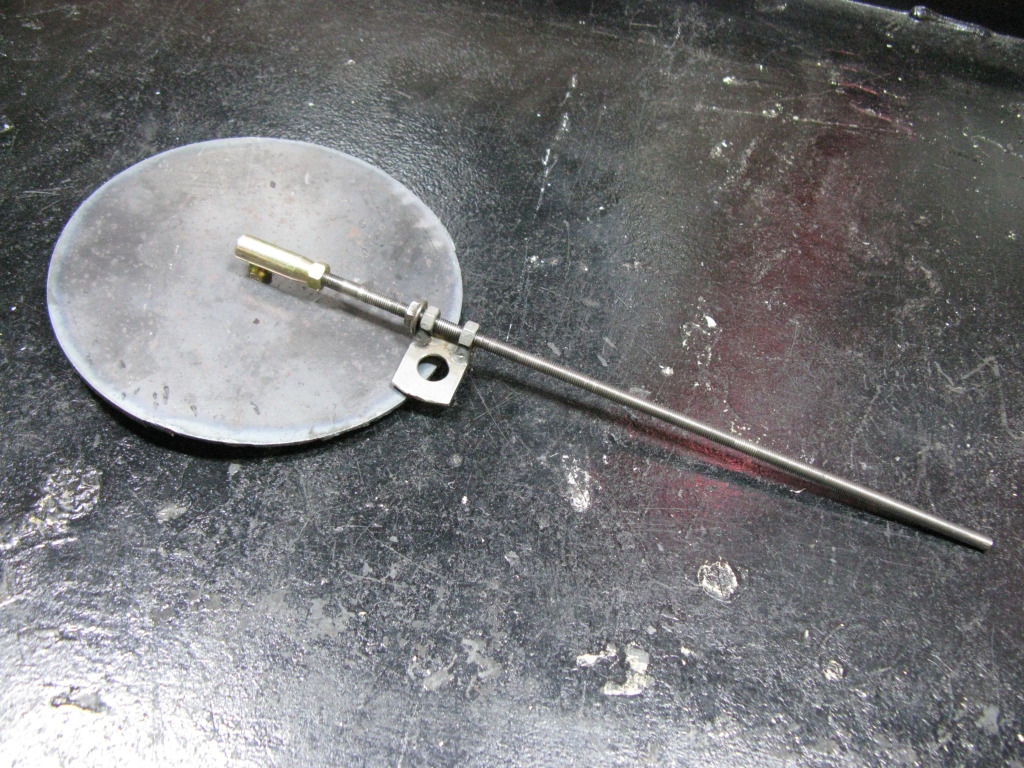

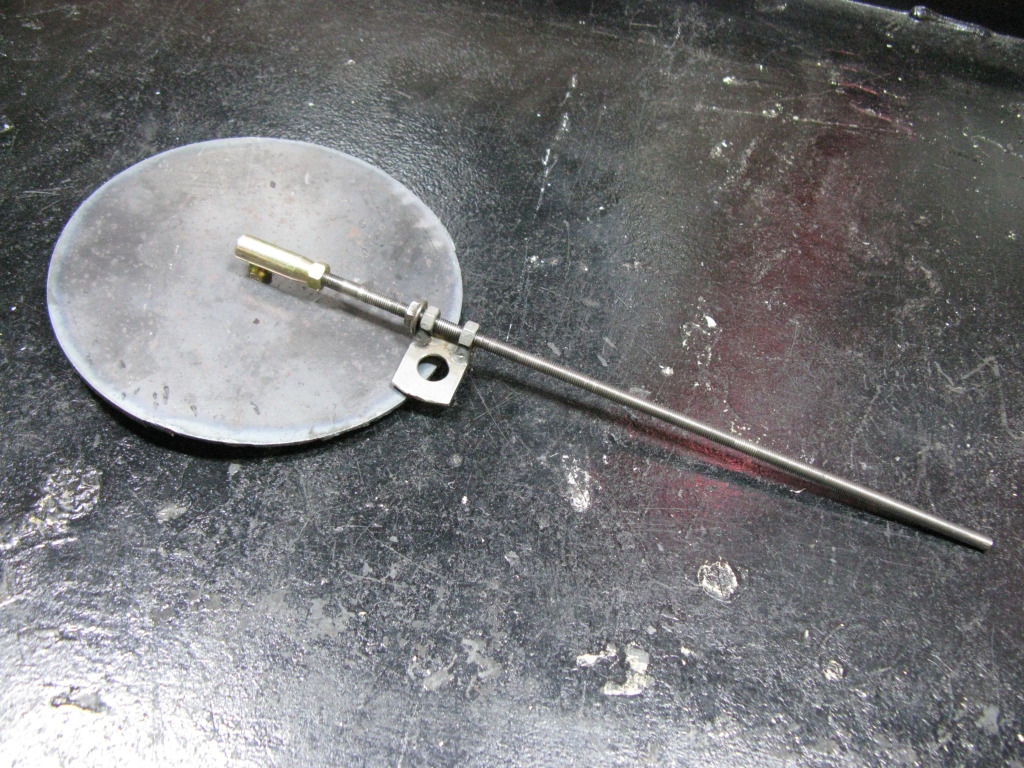

To cut a hole in the bottom plate for the tank to sit in I'm going to use my new fancy homemade circle cutter for my plasma cutter.

There is only going to be one bottle, when the one I have is empty I'm going to exchange for a bigger one.

I'm going to box in that square section between the rear wheels and then if you look at the first pic I posted you can see there's sort of a clamp that is welded to the back of the uprights to hold the top of the tank.

To cut a hole in the bottom plate for the tank to sit in I'm going to use my new fancy homemade circle cutter for my plasma cutter.

#5

I'm totally jealous of your set-up. I would totally have a ridiculous number of ideas for that cart to make it suit your needs.

I assume you don't want the footprint to be much bigger than that right? It could be as simple as a double hook system spaced about a foot apart on the side of each shelf. Wrap the hoses and cords around them. A piece of pipe around 5 inches long welded on at 45 degree angles can be a simple torch holder. Things like that.

You almost live close enough to me that I could buy you beer to let me use your Hobarts... Almost...

I assume you don't want the footprint to be much bigger than that right? It could be as simple as a double hook system spaced about a foot apart on the side of each shelf. Wrap the hoses and cords around them. A piece of pipe around 5 inches long welded on at 45 degree angles can be a simple torch holder. Things like that.

You almost live close enough to me that I could buy you beer to let me use your Hobarts... Almost...

#6

Yes the bottom two are both migs... 220v Handler 187 on the bottom and 110v Handler 140. I originally bought the 187 brand new with the intentions of just keeping it along with my plasma cutter. While looking for a bottle on Kijiji I came across a deal I couldn't pass up... basically got the 140 for free and it had only been used for 1/4 of a 2lb roll.

This way I can keep the thicker wire in the 187 for the heavy stuff and lighter in the 140 for anything lightweight work. That and it's nice to have the 110v to be able to take it outside if needed and plug into most outlets or if I need to weld something up somewhere else where 220 isn't available!

#7

I'm totally jealous of your set-up. I would totally have a ridiculous number of ideas for that cart to make it suit your needs.

I assume you don't want the footprint to be much bigger than that right? It could be as simple as a double hook system spaced about a foot apart on the side of each shelf. Wrap the hoses and cords around them. A piece of pipe around 5 inches long welded on at 45 degree angles can be a simple torch holder. Things like that.

You almost live close enough to me that I could buy you beer to let me use your Hobarts... Almost...

I assume you don't want the footprint to be much bigger than that right? It could be as simple as a double hook system spaced about a foot apart on the side of each shelf. Wrap the hoses and cords around them. A piece of pipe around 5 inches long welded on at 45 degree angles can be a simple torch holder. Things like that.

You almost live close enough to me that I could buy you beer to let me use your Hobarts... Almost...

Where do you live?

#9

Is it that obvious? lol.

Yes the bottom two are both migs... 220v Handler 187 on the bottom and 110v Handler 140. I originally bought the 187 brand new with the intentions of just keeping it along with my plasma cutter. While looking for a bottle on Kijiji I came across a deal I couldn't pass up... basically got the 140 for free and it had only been used for 1/4 of a 2lb roll.

This way I can keep the thicker wire in the 187 for the heavy stuff and lighter in the 140 for anything lightweight work. That and it's nice to have the 110v to be able to take it outside if needed and plug into most outlets or if I need to weld something up somewhere else where 220 isn't available!

Yes the bottom two are both migs... 220v Handler 187 on the bottom and 110v Handler 140. I originally bought the 187 brand new with the intentions of just keeping it along with my plasma cutter. While looking for a bottle on Kijiji I came across a deal I couldn't pass up... basically got the 140 for free and it had only been used for 1/4 of a 2lb roll.

This way I can keep the thicker wire in the 187 for the heavy stuff and lighter in the 140 for anything lightweight work. That and it's nice to have the 110v to be able to take it outside if needed and plug into most outlets or if I need to weld something up somewhere else where 220 isn't available!

On a side note, any reason they say the machines are for 120 and 230 volt receptacles rather than 110 and 120?

#11

Must be nice lol. Whats kijiji? is it only for around you or all across the US? I wish I could come across a deal like that. Im def going to be buying the new Millermatic 211 autoset that runs off both 220 and 110 as well as the gun for aluminum welding and the Miller spectrum 375 plasma cutter that runs off both 220 and 110 depending on your needs here soon. But they def aren't cheap for quality stuff!

On a side note, any reason they say the machines are for 120 and 230 volt receptacles rather than 110 and 120?

On a side note, any reason they say the machines are for 120 and 230 volt receptacles rather than 110 and 120?

Not sure why they say 230v and 120v. I always thought it was just 110 and 220. Who knows!

Quality stuff definitely isn't cheap... Hobart isn't top-of-the-line but I'm sure they'll work just fine for what I use them for. Can't complain when I have ~$1650 total into this whole setup. Plasma cutter, both welders, two auto darkening helmets, full tank of gas, all the materials I used to build the cart, extra regulator, plus an extra cart to sell now... and lots more little things!

#12

Thanks! One of the main things I wanted was a drawer... it's nice to keep everything together and it's deep enough to keep a couple pairs of gloves, pliers, extra wire, tips and just about anything else. It's 10x20x4".

#13

Kijiji is basically the same as Craigslist... I'm sure they have it down there too where CL is more common. We have CL here too but it's not very popular.

Not sure why they say 230v and 120v. I always thought it was just 110 and 220. Who knows!

Quality stuff definitely isn't cheap... Hobart isn't top-of-the-line but I'm sure they'll work just fine for what I use them for. Can't complain when I have ~$1650 total into this whole setup. Plasma cutter, both welders, two auto darkening helmets, full tank of gas, all the materials I used to build the cart, extra regulator, plus an extra cart to sell now... and lots more little things!

Not sure why they say 230v and 120v. I always thought it was just 110 and 220. Who knows!

Quality stuff definitely isn't cheap... Hobart isn't top-of-the-line but I'm sure they'll work just fine for what I use them for. Can't complain when I have ~$1650 total into this whole setup. Plasma cutter, both welders, two auto darkening helmets, full tank of gas, all the materials I used to build the cart, extra regulator, plus an extra cart to sell now... and lots more little things!

#14

#15

A funny side note, Hobart lists them as 115v or 230v, wtf why dont they just type it as the standard 110 or 220 electrical wirings that everyone says lol

#16

Howd you go about being an hobart fan over say lincoln or miller? Also I wouldnt say hobart is any cheaper, right now the hobart 210 that runs on both currents is only like 30 bucks cheaper than the miller 211 that I listed which are basically identical to easy other.

A funny side note, Hobart lists them as 115v or 230v, wtf why dont they just type it as the standard 110 or 220 electrical wirings that everyone says lol

A funny side note, Hobart lists them as 115v or 230v, wtf why dont they just type it as the standard 110 or 220 electrical wirings that everyone says lol

I've used Lincoln as well with no problems... just like to stick to one brand for the most part!

#17

Well like I said I literally just compared miller and hobart from both their websites and almost everything when compared to each other are all about the same prices new. Maybe miller being alittle more but really not that much more at all if not the same price. Like I said your big one is only 40 bucks cheaper than the miller one thats equal to it.

#18

#19

Did you make your own welding table? I have noticed lately since ive decided to get into welding more and more, that not having a table to weld on and always having to clamp the piece (especially if its something small) is getting very very difficult. Or trying to find something to clamp and hold my material or piece and give me good access and to weld to isn't cool. Im going to HAVE TO get my own welding table, or make one, etc.

EDIT: I also noticed your big kobalt compressor, do you remember how much you paid for it?

Im more of a craftsman guy vs kobalt or any of the other local brands but thats only because I worked for sears for a good while. Acourse now that all their hand tools just switched over from american to over seas has put a bad taste in my mouth. Now the only american options are really big money ones like snap on and others.

#20

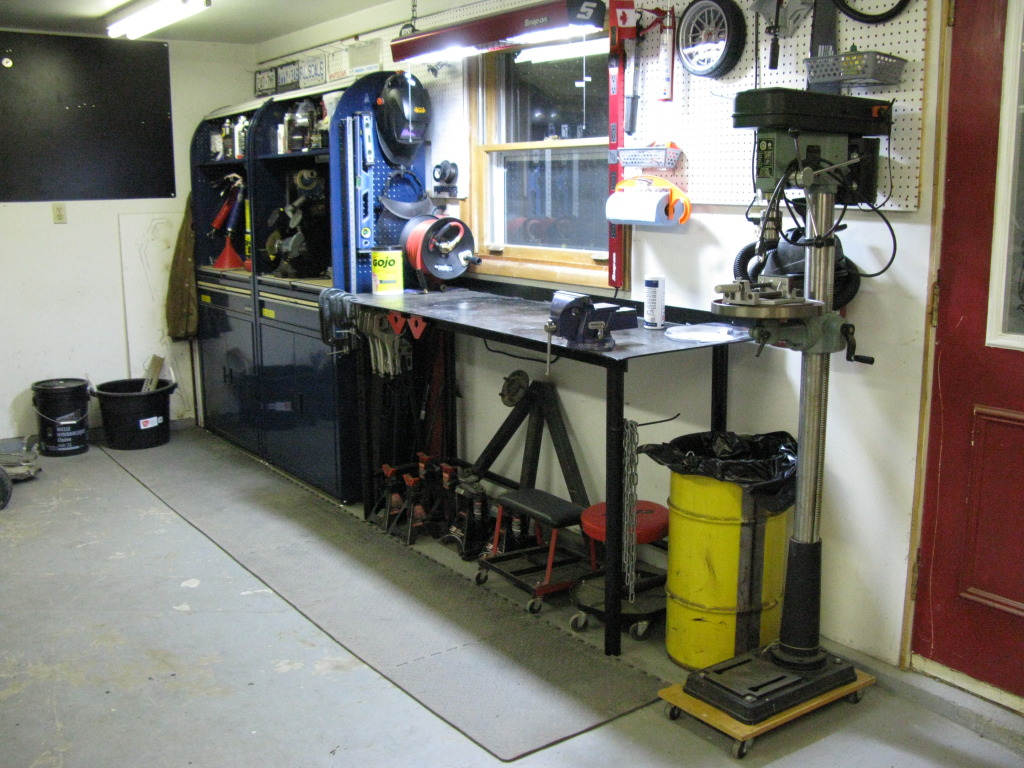

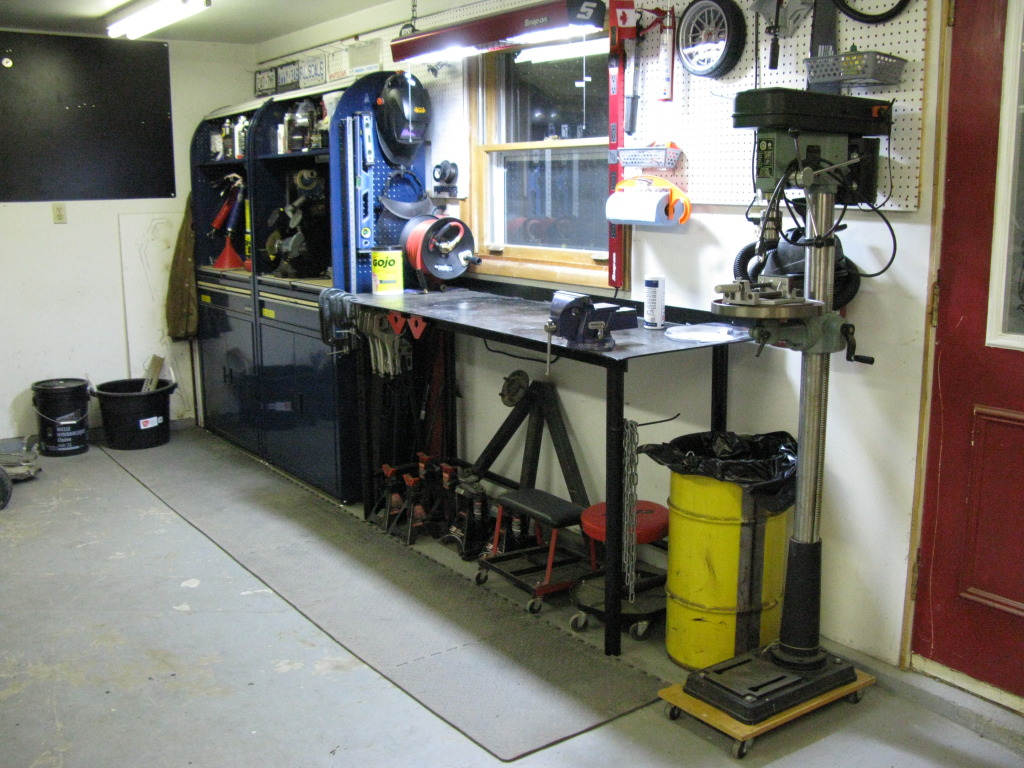

I don't have a "real" welding table... I have a fairly solid metal work bench that I use as well as some metal folding sawhorses (you can see them in the first two pics).

Here's the bench... That's shortly after I moved in so the air hose reel is mounted on the bottom and a few other things have changed.

Just today I picked up something else off Kijiji - a small used Northern Tool welding table. It's small but it's a nice height and it was cheap. Some day when I have a bigger shop I'll build a nice big welding table!

Here's the bench... That's shortly after I moved in so the air hose reel is mounted on the bottom and a few other things have changed.

Just today I picked up something else off Kijiji - a small used Northern Tool welding table. It's small but it's a nice height and it was cheap. Some day when I have a bigger shop I'll build a nice big welding table!

#22

#23

JEEEEEZ touch'e to you sir. Something comparable in craftsman right now would be 700-900 range depending on the options.

#24

I got it for $40... basically brand new. I would think a nice heavy steel top would be best. I not too knowledgeable in this stuff yet though... I'm pretty new to it as well.

#25

It's a pretty basic compressor though... it works fine for me as I don't use air tools that often. I don't imagine it'd do well painting or sandblasting. I've got air run up along he ceiling and then drops down to the workbench. I put a tee in halfway back so I can run across to the other side of the shop if I need to later.