SLP/Roush Thunderbolt Box w/ custom steel tube...no stock rubber junk! FIRST!!

#1

SLP/Roush Thunderbolt Box w/ custom steel tube...no stock rubber junk! FIRST!!

Hey.

I've been throwing this idea around for a long time now. I've ran a K&N FIPK2, I've ran the Thunderbolt w/ stock tube, I've ran MAC. Noticed instant power improvement when i installed the thunderbolt box w/ paper filter and stock tube compaired to the FIPK w/ a new filter. When i put the MAC on, i noticed instant decrease in power and the mac also had a new filter on it.

So....

Why not combine the best of both worlds? Thunderbolt box w/ a solid tube??? Get rid of that ugly 'crushing' of the tube.

This idea can be used on 2.5, 3.0, 2.3, 4.0's....whatever the Thunderbolt box will fit...this'll work for. This is regarding a 4.0L SOHC.

Tried to cut and fit the K&N plastic tube.....destroyed the tube and it still didn't work with the funky angles that the 3" bodylift provided with the thunderbolt box & MAF and the location of the Throttle Body. So.....

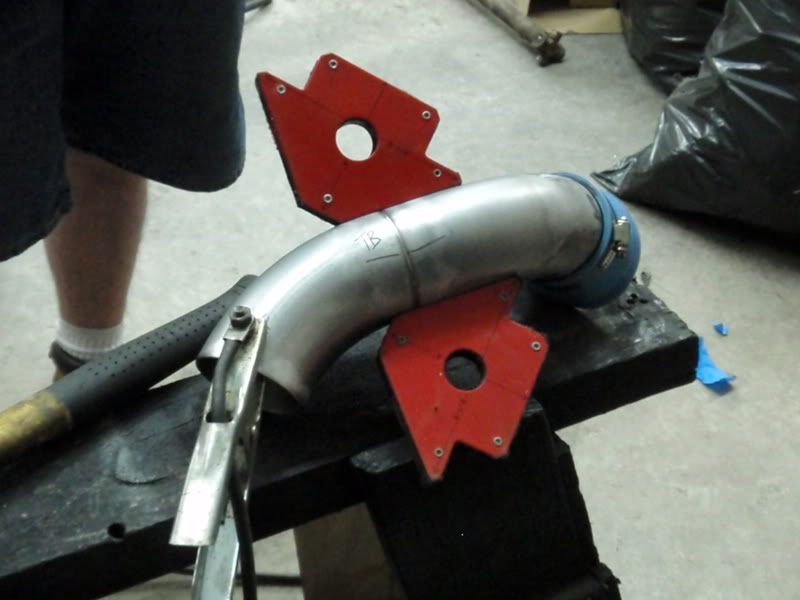

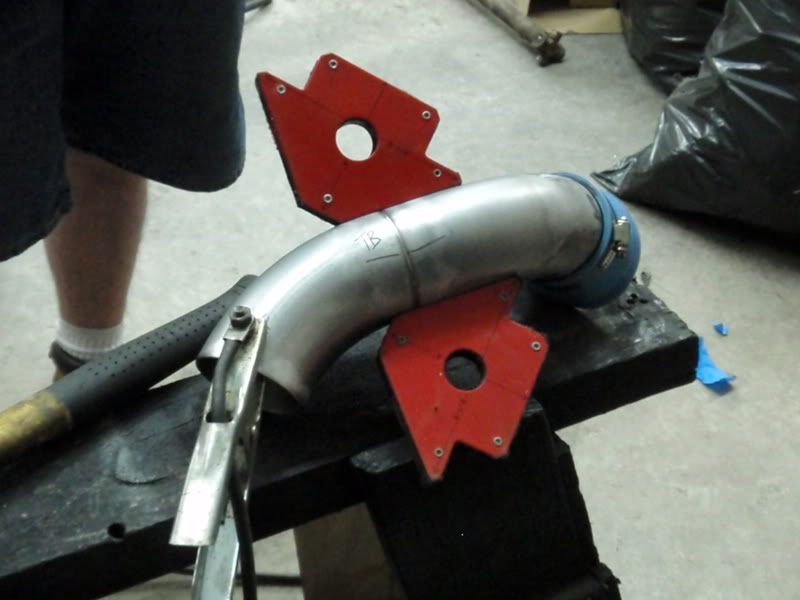

I went to the local intake/exhaust semi-truck warehouse(Air Flow Systems : http://www.airflo.com/ ) and picked up two 3" 45deg mandrell bends, and a 3ft stick of 3". Bend off the throttle body is more than 45, less than 90....so....i used a 45 and notched it to tighten the bend up to about *i'd guess* 65deg. Most of it being eye balling and comparing to the MAC tube. welded her up. kept checking and rechecking and regrinding to get the angle just right.

Now that the Thottle Body piece is done, time to mate it and the MAF together. This was the kinda difficult part....played around with little cuts of straight piece. Tried a straight piece coming off the MAF to an angled piece that matched another angle piece on the pipe already made(joining round to an oval is definaltey not doable).

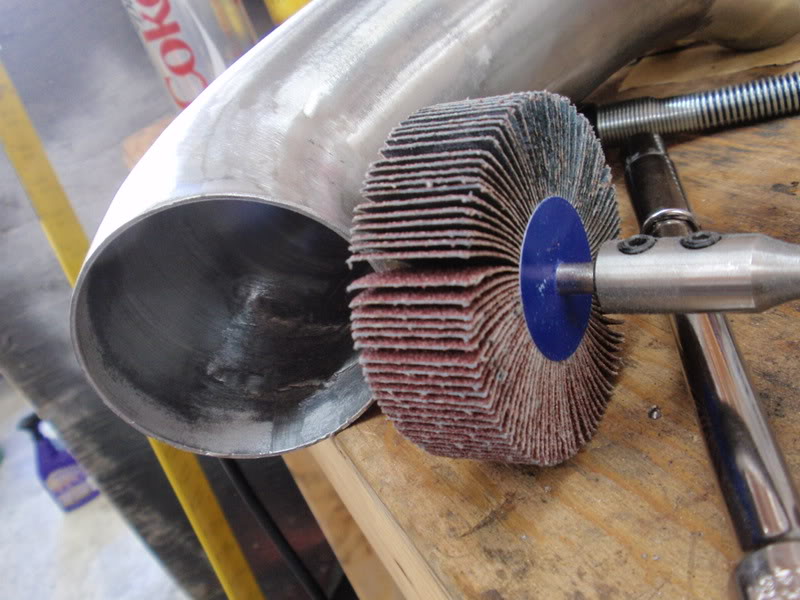

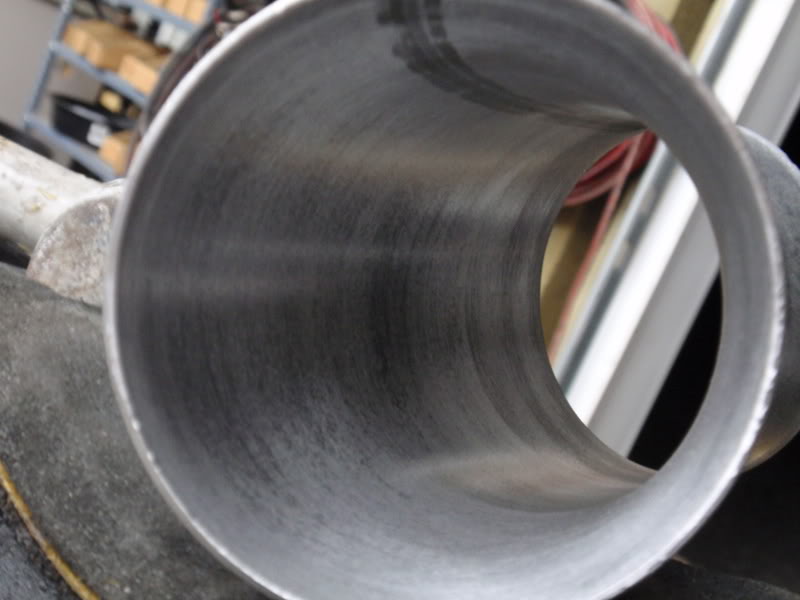

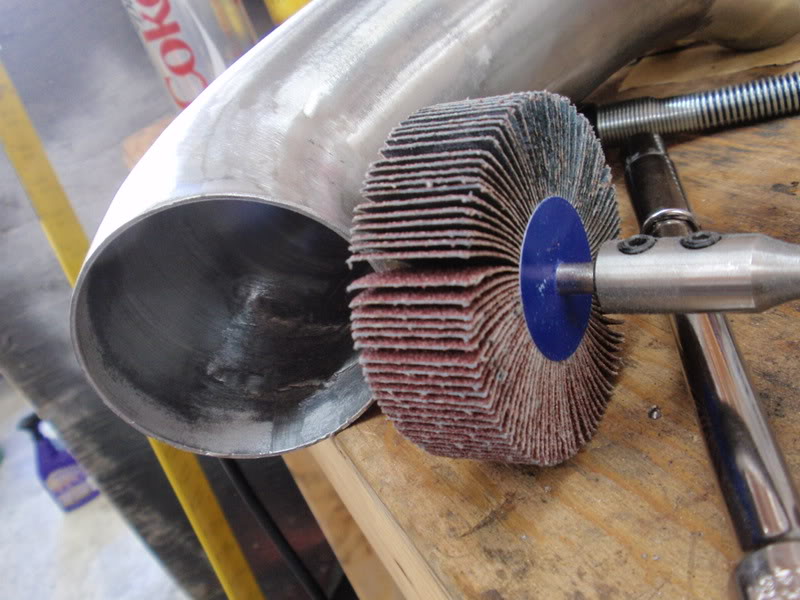

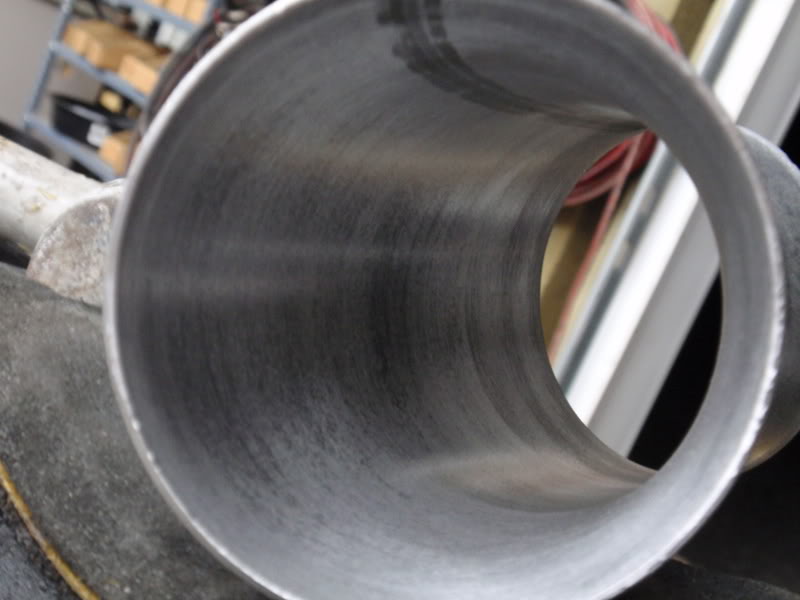

After standing back...looking at it....i could just cut the straights off the extra 45 i have, and gues what....fit freaking perfect. After pieceing them all together, mocking/test fitting them into place....BAM! fits perfect. made my alignment marks. Welded her up, took 80grit flap disc to it to smooth it all out. Took the dremel to the welds and cut marks on the inside to clean it up....inside it's alsmost completely flat. After that took a 60g flap drill wheel to it....and that made the inside silky smooth.

I will be ordering up a new filter for it. It'll be one of those new AEM Dryflow's and i'll be wrapping it for winter wheeling and winter weather. Drives awesome and is just GREAT in the cooling department(i have a scangauge). Still need to weld a 5/8" tube so that i can run that tube from the valve cover to the intake. Only problem still....is well...it's a steel tube, so it get really really hot. I plan to cure that with fiberglass header wrap or something similar. Even possibly ceramic coating. Any ideas?

On with the pics...

Notice funky angle at the MAF...

I've been throwing this idea around for a long time now. I've ran a K&N FIPK2, I've ran the Thunderbolt w/ stock tube, I've ran MAC. Noticed instant power improvement when i installed the thunderbolt box w/ paper filter and stock tube compaired to the FIPK w/ a new filter. When i put the MAC on, i noticed instant decrease in power and the mac also had a new filter on it.

So....

Why not combine the best of both worlds? Thunderbolt box w/ a solid tube??? Get rid of that ugly 'crushing' of the tube.

This idea can be used on 2.5, 3.0, 2.3, 4.0's....whatever the Thunderbolt box will fit...this'll work for. This is regarding a 4.0L SOHC.

Tried to cut and fit the K&N plastic tube.....destroyed the tube and it still didn't work with the funky angles that the 3" bodylift provided with the thunderbolt box & MAF and the location of the Throttle Body. So.....

I went to the local intake/exhaust semi-truck warehouse(Air Flow Systems : http://www.airflo.com/ ) and picked up two 3" 45deg mandrell bends, and a 3ft stick of 3". Bend off the throttle body is more than 45, less than 90....so....i used a 45 and notched it to tighten the bend up to about *i'd guess* 65deg. Most of it being eye balling and comparing to the MAC tube. welded her up. kept checking and rechecking and regrinding to get the angle just right.

Now that the Thottle Body piece is done, time to mate it and the MAF together. This was the kinda difficult part....played around with little cuts of straight piece. Tried a straight piece coming off the MAF to an angled piece that matched another angle piece on the pipe already made(joining round to an oval is definaltey not doable).

After standing back...looking at it....i could just cut the straights off the extra 45 i have, and gues what....fit freaking perfect. After pieceing them all together, mocking/test fitting them into place....BAM! fits perfect. made my alignment marks. Welded her up, took 80grit flap disc to it to smooth it all out. Took the dremel to the welds and cut marks on the inside to clean it up....inside it's alsmost completely flat. After that took a 60g flap drill wheel to it....and that made the inside silky smooth.

I will be ordering up a new filter for it. It'll be one of those new AEM Dryflow's and i'll be wrapping it for winter wheeling and winter weather. Drives awesome and is just GREAT in the cooling department(i have a scangauge). Still need to weld a 5/8" tube so that i can run that tube from the valve cover to the intake. Only problem still....is well...it's a steel tube, so it get really really hot. I plan to cure that with fiberglass header wrap or something similar. Even possibly ceramic coating. Any ideas?

On with the pics...

Notice funky angle at the MAF...

#10

so wait.. you havent done anything for the breath valve yet? why not do this?? (http://www.tgilmore.com/talon/catchcan.html)

#15

Thanks ya'll...

pretty sure ya'lls are joking about the breather filter? I was thinking about just doing what my old chevy has....just breathers off the valve cover. But idk.

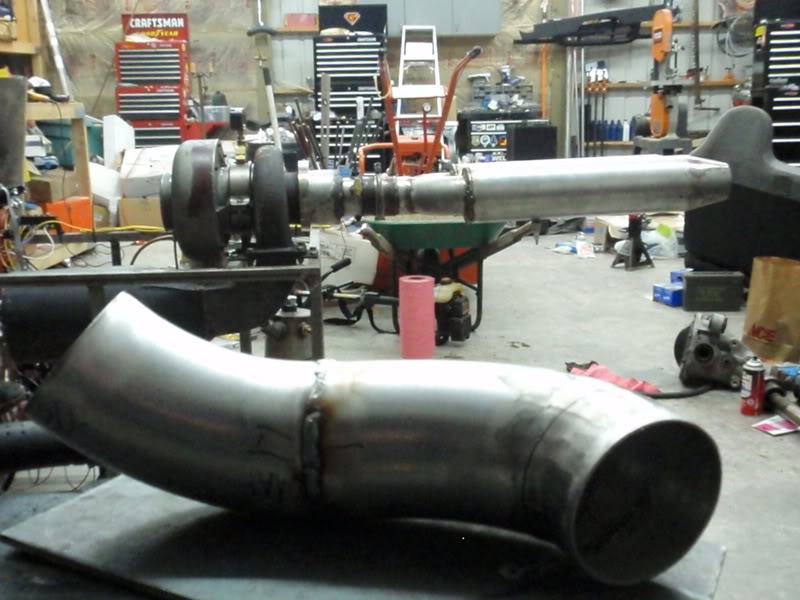

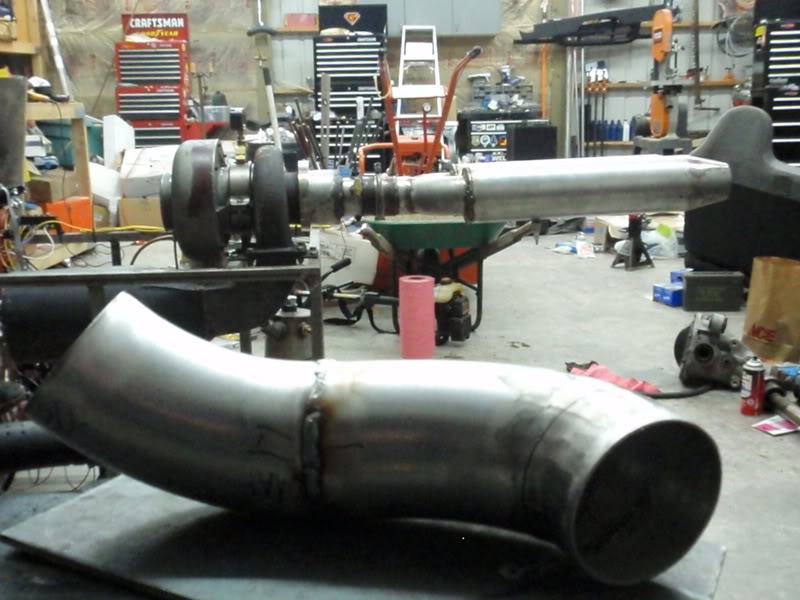

The newly AFTERBURNER'd Jet engine is my little brothers. It's his second he's built, he's on his 2nd or 3rd turbo in the pics. I should have a thread showing his stuff off....or make him make a thread! lol. There's vids on you tube. Search my user id 'fx4wannabe01' and you'll see the vids. This kids a genious. He's 19 and such a smart smart kid. I'm so proud of him. *cheesy moment there sorry. He fabbed everything himself. Afterburner has yet to be tested. Still working out the kinks from the recent 'incident' where the intake side twisted at the clamp.....lets just say major internal carnage and 8ft flames.

ok....back to my mod....

Results.

VERY noticable power gain even with the paper filter. At about 3500, she opens up really good.....next thing you know you're at 5500 and time to shift. I'd even say she's 'fast' again! It feels great, sounds great, and performs wonderfully. I'm seeing cooler incoming air now compared to the tbolt box and the stock tube via the scangaugeII. VERY good easy $30 mod. I think after everything, i'll have about $120 into this intake. (used 3.0L tbolt box $40, new aem dryflow $40, 2- 45* bends $30, clamps $8, and trying to find black couplers so i can sell my MAC intake.). Hell....Austin and I came up with a semi ram-air for his truck....more on that later....

Oh yea. Kayak. That's the normal chew can holder when working on the truck when the core support is full. lol.

pretty sure ya'lls are joking about the breather filter? I was thinking about just doing what my old chevy has....just breathers off the valve cover. But idk.

The newly AFTERBURNER'd Jet engine is my little brothers. It's his second he's built, he's on his 2nd or 3rd turbo in the pics. I should have a thread showing his stuff off....or make him make a thread! lol. There's vids on you tube. Search my user id 'fx4wannabe01' and you'll see the vids. This kids a genious. He's 19 and such a smart smart kid. I'm so proud of him. *cheesy moment there sorry. He fabbed everything himself. Afterburner has yet to be tested. Still working out the kinks from the recent 'incident' where the intake side twisted at the clamp.....lets just say major internal carnage and 8ft flames.

ok....back to my mod....

Results.

VERY noticable power gain even with the paper filter. At about 3500, she opens up really good.....next thing you know you're at 5500 and time to shift. I'd even say she's 'fast' again! It feels great, sounds great, and performs wonderfully. I'm seeing cooler incoming air now compared to the tbolt box and the stock tube via the scangaugeII. VERY good easy $30 mod. I think after everything, i'll have about $120 into this intake. (used 3.0L tbolt box $40, new aem dryflow $40, 2- 45* bends $30, clamps $8, and trying to find black couplers so i can sell my MAC intake.). Hell....Austin and I came up with a semi ram-air for his truck....more on that later....

Oh yea. Kayak. That's the normal chew can holder when working on the truck when the core support is full. lol.

Last edited by Fx4wannabe01; 09-13-2008 at 10:53 PM.

#16

idk, ask knightmare.

umm....no. lol. Way too many variables imo. But i think i have all the engines at my disposal, except the 01+ 2.3.

I only rock the TBspacer because i like the whistle. I recieved the best mileage with it and a bunch of other stuff....so why change something that's working' good. NO CLUE if the TBspacer adds anything whatsoever. Roush intakes are not avaliable anymore. Been out of production since '03?

hmmm....might be able to make that happen...

Idk yet. Grant, the lil bro, knows how to tig, so i think i'll do a normal aftermarket intake style....5/8 pipe welded to the tube. Rubber hose between it and the plastic stock tube. Yea.....nobody at work recognized me. shaved the head and the face. lol.

Too bad I don't have a 2.3L at my disposal to mock up off of. If i did, i'd be all over that.

umm....no. lol. Way too many variables imo. But i think i have all the engines at my disposal, except the 01+ 2.3.

hmmm....might be able to make that happen...

Too bad I don't have a 2.3L at my disposal to mock up off of. If i did, i'd be all over that.

#20

#21

hmmm......i might have to take you up on that offer. Thinking about ceramic coating...like a graphite color. but idk.

Anyway....there should be an update tomorrow. I took the tube off after running it for a week. I forgot.....bare steel + wet/humid environment = rust. lol. So got that taken care of for now. Still need to put the steel tube back on tho....those 'exi chrome' paints take a long long long time to cure.

Update will be tomorrow.

Anyway....there should be an update tomorrow. I took the tube off after running it for a week. I forgot.....bare steel + wet/humid environment = rust. lol. So got that taken care of for now. Still need to put the steel tube back on tho....those 'exi chrome' paints take a long long long time to cure.

Update will be tomorrow.

#22

I dont have the stuff to do ceramic coatings, most of them are solvent based spray on liquids that have to cure in an oven at 750F degrees for an hour. I've read/heard with headers at least you can partially cure it at 500F for like 20 mins and put them on the engine and let the engine heat cure them for an hour (while running). It is good to 2000F degrees though lol. My oven cant accurately maintain temperatures that high. Most powder coatings are cured between 250F and 450F. If you can produce the heat it's not that expensive, $20 for the ceramic coating and $20 for the touch-up spray gun or an airbrush.

But what I think you'd like is a black chrome powder coat. I cant attach a picture since I'm at work but here's a link with a picture.

http://store.columbiacoatings.com/cg...ategory%3DMTPW

And here's a link of the ceramic stuff.

http://store.columbiacoatings.com/cg...on&parent=CRPW

But what I think you'd like is a black chrome powder coat. I cant attach a picture since I'm at work but here's a link with a picture.

http://store.columbiacoatings.com/cg...ategory%3DMTPW

And here's a link of the ceramic stuff.

http://store.columbiacoatings.com/cg...on&parent=CRPW