1999 B3000 - Slight Jerking While Driving

#1

1999 B3000 - Slight Jerking While Driving

As the title says.

I replaced the Camshaft Sync sensor and the Ford dealer let me borrow the sync tool over night _ it was out more then 90 degrees with number one on compression and at TDC.

I cleaned the MAF sensor and the truck is running pretty good now, but I'm still getting codes for "PCM" and "EVAP"

I cleaned the grounds, the rest of the engine sensors and the big PCM connector.

I reset the PCM by disconnecting the battery and connecting the negative and positive grounds together.

This seemed to have taken care of the codes as the "Check Engine" light has not come back on.

I'm thinking that the dirty connections and bad grounds were giving a false positive.

I believe the problem that's causing the jerking/lurching may be a dirty and sticky IAC valve.

I say this because the idle seems a bit high at just below 1000 RPM.

Sometimes in rests at just above 1000, but touching the accelerator peddle will return it just below a 1000.

The problem is noticeable at sustained slow speeds, anything below 35 MPH, but it's there even at highway speeds, but barely noticeable because the truck is moving too fast.

I think a dirty IAC valve won't cause the check engine light to come on.

Any help on this would be much appreciated !

Should I try cleaning the valve or just get a new one, or is it something else ?

The valve it self did look pretty sooty when I cleaned the carbon chunks of the throttle control valve.

I replaced the Camshaft Sync sensor and the Ford dealer let me borrow the sync tool over night _ it was out more then 90 degrees with number one on compression and at TDC.

I cleaned the MAF sensor and the truck is running pretty good now, but I'm still getting codes for "PCM" and "EVAP"

I cleaned the grounds, the rest of the engine sensors and the big PCM connector.

I reset the PCM by disconnecting the battery and connecting the negative and positive grounds together.

This seemed to have taken care of the codes as the "Check Engine" light has not come back on.

I'm thinking that the dirty connections and bad grounds were giving a false positive.

I believe the problem that's causing the jerking/lurching may be a dirty and sticky IAC valve.

I say this because the idle seems a bit high at just below 1000 RPM.

Sometimes in rests at just above 1000, but touching the accelerator peddle will return it just below a 1000.

The problem is noticeable at sustained slow speeds, anything below 35 MPH, but it's there even at highway speeds, but barely noticeable because the truck is moving too fast.

I think a dirty IAC valve won't cause the check engine light to come on.

Any help on this would be much appreciated !

Should I try cleaning the valve or just get a new one, or is it something else ?

The valve it self did look pretty sooty when I cleaned the carbon chunks of the throttle control valve.

#2

IAC Valve is just used at idle, so can't cause problems when driving.

After engine is warmed up, let it idle and unplug the wires on the IAC Valve, it will close and idle should drop to 500RPM or engine may even stall, either is GOOD, it means no Vacuum Leaks.

If idle stays above 700rpm then you have a leak.

A vacuum leak can cause what you describe.

With IAC valve still unplugged, and engine still idling, pull off vacuum hoses from intake, one at a time, and plug the hole with your finger, if idle drops down then that hose/device has the leak.

If all hoses check out OK then you will need to wait until engine is stone cold, overnight.

get a can of Quick Start(ether)

When engine is stone cold

Loosen fan belt and remove it from the crank pulley.

This will stop the fan from blowing, and water pump as well, so you can only run the engine for 2 or 3 minutes.

Start engine, Battery Light will stay on..........no alternator, but that's OK for a couple of minutes

Spray the Quick Start around the throttle body, and lower intake near valve covers.

Engine RPMs will change, you will hear it, if the Ether is sucked in thru a leak

After engine is warmed up, let it idle and unplug the wires on the IAC Valve, it will close and idle should drop to 500RPM or engine may even stall, either is GOOD, it means no Vacuum Leaks.

If idle stays above 700rpm then you have a leak.

A vacuum leak can cause what you describe.

With IAC valve still unplugged, and engine still idling, pull off vacuum hoses from intake, one at a time, and plug the hole with your finger, if idle drops down then that hose/device has the leak.

If all hoses check out OK then you will need to wait until engine is stone cold, overnight.

get a can of Quick Start(ether)

When engine is stone cold

Loosen fan belt and remove it from the crank pulley.

This will stop the fan from blowing, and water pump as well, so you can only run the engine for 2 or 3 minutes.

Start engine, Battery Light will stay on..........no alternator, but that's OK for a couple of minutes

Spray the Quick Start around the throttle body, and lower intake near valve covers.

Engine RPMs will change, you will hear it, if the Ether is sucked in thru a leak

#3

#4

It would seem that is has a vacuum leak, I pulled off the IAC valve connection and the idle only dropped to 700 rpm.

Plugging it back in and unplugging it again made very little difference. It remained at around 1000 rpm after a while.

I think the IAC valve is faulty too, when I removed the throttle body to clean it, I removed the IAC valve and I could easily blow through its ports.

According to your post here it should be shut right off with no voltage applied.

https://www.ranger-forums.com/2-9l-3...8/#post2107170

When I first got the tuck I was checking for vacuum leaks and when I apply vacuum here (see screen shot) with my pump, it holds no vacuum at all, is this normal ?

That of course is the EVAP Canister Purge Valve.

With its electrical connection unplugged or plugged in, it holds no vacuum.

Note that with the engine running, pulling the vacuum line off the Canister Purge Valve and plugging it with my finger has no affect on the idle..

Plugging it back in and unplugging it again made very little difference. It remained at around 1000 rpm after a while.

I think the IAC valve is faulty too, when I removed the throttle body to clean it, I removed the IAC valve and I could easily blow through its ports.

According to your post here it should be shut right off with no voltage applied.

https://www.ranger-forums.com/2-9l-3...8/#post2107170

When I first got the tuck I was checking for vacuum leaks and when I apply vacuum here (see screen shot) with my pump, it holds no vacuum at all, is this normal ?

That of course is the EVAP Canister Purge Valve.

With its electrical connection unplugged or plugged in, it holds no vacuum.

Note that with the engine running, pulling the vacuum line off the Canister Purge Valve and plugging it with my finger has no affect on the idle..

Last edited by Jeff R 1; 07-10-2016 at 04:01 PM.

#5

As far as I know it should hold vacuum if other vacuum port on it is plugged.

There are two hoses to the intake manifold, the smaller one you are asking about and the larger one next to the port that goes to fuel tank.

But have to say I never tested a 3 port model, most are 2 port.

If you plug the IAC valve in and then turn on the key you should be able to see valve move full open, then unplug it and it should close all the way.

Never tried blowing thru one

There are two hoses to the intake manifold, the smaller one you are asking about and the larger one next to the port that goes to fuel tank.

But have to say I never tested a 3 port model, most are 2 port.

If you plug the IAC valve in and then turn on the key you should be able to see valve move full open, then unplug it and it should close all the way.

Never tried blowing thru one

#6

I think the IAC valve is faulty _ it doesn't move at all _ it stays open all the time.

I took it off and I applied 12 volts to it and it didn't move and when I removed the 12 volt source, it stayed open.

I tried reversing the polarity and no change in the action.

I can hear the solenoid clicking, but no movement in the valve.

And thank you, it's very difficult to find someone who knows about these things and is willing to help.

The Mazda forum "Mazdaforums.org" is pretty useless _ unfortunately.

I can see where it's supposed to be seated, but it never rests on the seat.

I can close it onto the seat with a screw driver and I can't blow through it.

It appears to be jammed.

I took it off and I applied 12 volts to it and it didn't move and when I removed the 12 volt source, it stayed open.

I tried reversing the polarity and no change in the action.

I can hear the solenoid clicking, but no movement in the valve.

And thank you, it's very difficult to find someone who knows about these things and is willing to help.

The Mazda forum "Mazdaforums.org" is pretty useless _ unfortunately.

I can see where it's supposed to be seated, but it never rests on the seat.

I can close it onto the seat with a screw driver and I can't blow through it.

It appears to be jammed.

#7

yes, reads like IAC is bad.

Solenoid on it should be 7-14ohms, and test each pin to Case, should be N/C no connection or above 10,000 ohms, you will often see an internal short to the case when they fail.

IAC valve uses PWM(pulse width modulation) basically 12volts pulsing very fast, this causes solenoid to move to a certain spot and hang there, because spring on valve is trying to push it closed, opposite direction 12volts is pushing it, so wider pulse closes valve a bit, shorter pulse opens it a bit, no volts and valve closes.

EVAP and EGR solenoids use similar, to vary vacuum levels

Solenoid on it should be 7-14ohms, and test each pin to Case, should be N/C no connection or above 10,000 ohms, you will often see an internal short to the case when they fail.

IAC valve uses PWM(pulse width modulation) basically 12volts pulsing very fast, this causes solenoid to move to a certain spot and hang there, because spring on valve is trying to push it closed, opposite direction 12volts is pushing it, so wider pulse closes valve a bit, shorter pulse opens it a bit, no volts and valve closes.

EVAP and EGR solenoids use similar, to vary vacuum levels

Last edited by RonD; 07-10-2016 at 07:49 PM.

#9

#10

So it looks like a vacuum leak after all.

Rather then start searching through all the vacuum lines I just plugged of the main vacuum port on the manifold.

Driving it like that seemed to have cured the loping/jerking problem and pulling the connection of the IAC dropped the idle to 500 rpm.

It would seem that the IAC is OK after-all, but when I compare the action to the new one (I haven't bough it yet) the plunger goes in one direction only.

Although both are in the open position when unplugged.

However, but because the old valve doesn't move at all when energized it still may be faulty, although it does affect the engine idle pulling the connection off, so it must be doing something.

I just don't know and I don't have enough experience to know how it's supposed to react.

Also, the check engine light just came back on, so I have to go back to the mechanic and find out what that's about.

(the check engine light came on before I pulled the main vacuum port and plugged the manifold, just in case you were thinking that, that cased the light to come on)

At this point I'm developing a healthy dislike for fuel injection.

It's too complicated for it's own good trying to manage an antiquated internal combustion engine that hasn't really changed in more then a 100 years in its design.

My little rant there...

Rather then start searching through all the vacuum lines I just plugged of the main vacuum port on the manifold.

Driving it like that seemed to have cured the loping/jerking problem and pulling the connection of the IAC dropped the idle to 500 rpm.

It would seem that the IAC is OK after-all, but when I compare the action to the new one (I haven't bough it yet) the plunger goes in one direction only.

Although both are in the open position when unplugged.

However, but because the old valve doesn't move at all when energized it still may be faulty, although it does affect the engine idle pulling the connection off, so it must be doing something.

I just don't know and I don't have enough experience to know how it's supposed to react.

Also, the check engine light just came back on, so I have to go back to the mechanic and find out what that's about.

(the check engine light came on before I pulled the main vacuum port and plugged the manifold, just in case you were thinking that, that cased the light to come on)

At this point I'm developing a healthy dislike for fuel injection.

It's too complicated for it's own good trying to manage an antiquated internal combustion engine that hasn't really changed in more then a 100 years in its design.

My little rant there...

#11

If idle dropped when IAC was unplugged then it is closing, moving, it's unpowered state is closed.

If code is EVAP then EVAP solenoid is probably the leak.

Been working on engines alot of years, carb vacuum leaks can also be a "chase your tail" event, lol.

And approach all modern engine problems like it is a mechanical issue, computers and sensors are so far down on the list of possible problems that they shouldn't even be considered.

Solenoids like IAC and EVAP/EGR are mechanical devices, they move so will wear out.

And just as a heads up.

90% of all sensors replaced on a modern engine by DIYers were working fine, simple act of replacing them fixed wiring issue or other actual problem.

But don't feel too bad.......

50% of all sensors replaced on a modern engine by Professional Mechanics were working fine, but I think this was do to laziness and bill padding, laziness in that they replaced a sensor rather than testing it, and the dirty connector causing the problem was now making a good connection so problem solved.

If code is EVAP then EVAP solenoid is probably the leak.

Been working on engines alot of years, carb vacuum leaks can also be a "chase your tail" event, lol.

And approach all modern engine problems like it is a mechanical issue, computers and sensors are so far down on the list of possible problems that they shouldn't even be considered.

Solenoids like IAC and EVAP/EGR are mechanical devices, they move so will wear out.

And just as a heads up.

90% of all sensors replaced on a modern engine by DIYers were working fine, simple act of replacing them fixed wiring issue or other actual problem.

But don't feel too bad.......

50% of all sensors replaced on a modern engine by Professional Mechanics were working fine, but I think this was do to laziness and bill padding, laziness in that they replaced a sensor rather than testing it, and the dirty connector causing the problem was now making a good connection so problem solved.

Last edited by RonD; 07-12-2016 at 11:13 AM.

#12

Thanks for the different approach on how to look at things _ that simplifies it allot.

Went back to Dave the mechanic today and the check engine light came on because of the plugging and unplugging of the IAC plug _ go figure.

But I was more interested to see if the PCM code came up again, but it's fine.

And that fits right in with your "the sensors are not broken, just dirty connections and/or bad grounds" advice.

I've been working on engines myself since high school (30 years), all carbureted of course, so lots of practical experience there.

I've been doing lots of searching on just how the valve works on the 1999 3 litre engine and what I've found is that the vacuum of the engine pulls the valve shut when it's disconnected from the PCM.

The PCM works against the vacuum of the engine.

The engine doesn't stall right out because there is a small round hole in the middle of the butter fly valve on the throttle body.

It actually idles quite nice at 500 rpm, but too slow for the PCM to accept, so the engine light came on.

The new IAC valve is not fully closed against its seat either when no voltage is applied to it, so it looks like my old one is OK.

I still may get the new one anyway just to be sure, it's only 51.00 bucks.

With the main vacuum port plugged of, it idles at around 800 rpm, which I think is acceptable.

I'll start my vacuum leak hunt by checking one circuit at a time starting with the EGR _ it does ping a bit if I gun it up a hill, but with carful driving it doesn't ping.

Went back to Dave the mechanic today and the check engine light came on because of the plugging and unplugging of the IAC plug _ go figure.

But I was more interested to see if the PCM code came up again, but it's fine.

And that fits right in with your "the sensors are not broken, just dirty connections and/or bad grounds" advice.

I've been working on engines myself since high school (30 years), all carbureted of course, so lots of practical experience there.

I've been doing lots of searching on just how the valve works on the 1999 3 litre engine and what I've found is that the vacuum of the engine pulls the valve shut when it's disconnected from the PCM.

The PCM works against the vacuum of the engine.

The engine doesn't stall right out because there is a small round hole in the middle of the butter fly valve on the throttle body.

It actually idles quite nice at 500 rpm, but too slow for the PCM to accept, so the engine light came on.

The new IAC valve is not fully closed against its seat either when no voltage is applied to it, so it looks like my old one is OK.

I still may get the new one anyway just to be sure, it's only 51.00 bucks.

With the main vacuum port plugged of, it idles at around 800 rpm, which I think is acceptable.

I'll start my vacuum leak hunt by checking one circuit at a time starting with the EGR _ it does ping a bit if I gun it up a hill, but with carful driving it doesn't ping.

Last edited by Jeff R 1; 07-12-2016 at 08:39 PM.

#13

The first thing I did was check the vacuum harness. I did this by removing it from the engine bay, plugging off all the ends and applying vacuum _ the lines tested fine _ it held vacuum for a number of hours.

The first system I hooked back up was the EGR and it turns that the vacuum leak is coming from the "Vacuum Regulator Solenoid" or at least its malfunctioning in a way that's causing the very annoying jerking while driving.

Disconnecting the red vacuum line from the valve and plugging that line off stops the jerking. The other line coming from the valve is green and is of course connected the EGR valve itself.

That's a relief since if it was the vacuum controls in the dash, that would have been a big job getting into that.

I will also be checking the DPFE sensor _ apparently that can become quite problematic.

The two lines coming in and out can get plugged.

I don't know if a faulty DPFE sensor can affect the proper vacuum function of the Vacuum Regulator Solenoid, however at this point it would seem that the diaphragm in it has failed, causing the vacuum leak.

The first system I hooked back up was the EGR and it turns that the vacuum leak is coming from the "Vacuum Regulator Solenoid" or at least its malfunctioning in a way that's causing the very annoying jerking while driving.

Disconnecting the red vacuum line from the valve and plugging that line off stops the jerking. The other line coming from the valve is green and is of course connected the EGR valve itself.

That's a relief since if it was the vacuum controls in the dash, that would have been a big job getting into that.

I will also be checking the DPFE sensor _ apparently that can become quite problematic.

The two lines coming in and out can get plugged.

I don't know if a faulty DPFE sensor can affect the proper vacuum function of the Vacuum Regulator Solenoid, however at this point it would seem that the diaphragm in it has failed, causing the vacuum leak.

#14

No, the DPFE sensor is not part of the vacuum system, the hoses go to exhaust manifold/EGR tube, one closer to EGR valve one farther away, as EGR valve opens the pressure difference between the 2 hoses tells computer how much exhaust gas is pass thru to intake manifold.

DPFE = Delta or Differential pressure feedback

One of the by-products of burning gasoline(H) with oxygen(O) is H2O, water, which is why tail pipes drip water, and blow out "stream" in cold weather, it is also why exhaust systems rust from the inside out, lol.

The DPFE sensor and hoses cool off faster than exhaust manifold/EGR tube, and like a cold glass of beer on a hot day the cooler parts get condensation build up, water forms on the outside of the glass and the inside of the DPFE sensor and hoses.

This water builds up sediment inside sensor and hoses, and sensor will fail over time and hoses get clogged up, so not a bad idea to clean hoses once a year.

DPFE = Delta or Differential pressure feedback

One of the by-products of burning gasoline(H) with oxygen(O) is H2O, water, which is why tail pipes drip water, and blow out "stream" in cold weather, it is also why exhaust systems rust from the inside out, lol.

The DPFE sensor and hoses cool off faster than exhaust manifold/EGR tube, and like a cold glass of beer on a hot day the cooler parts get condensation build up, water forms on the outside of the glass and the inside of the DPFE sensor and hoses.

This water builds up sediment inside sensor and hoses, and sensor will fail over time and hoses get clogged up, so not a bad idea to clean hoses once a year.

#15

Thanks Ron.

Do you know how the Vacuum Regulator Solenoid is supposed to work concerning the vacuum.

I cleaned it (it was very dirty) and it made no difference.

Here is how mine is working:

I apply vacuum (with a vacuum pump) to the bottom port where there would normally be manifold vacuum.

I plug off the top port and apply vacuum and it holds nothing _ I can here the breather at the top of the valve where the dust filter is letting in vacuum.

Is it supposed to do that ?

That would cause the leak, that's for sure.

If I apply 12 volts to the solenoid and do the procedure as above, then it will hold vacuum reasonably well (reasonably well meaning that it will leak down with in a number of seconds), but it won't hold it for more then a minute if I pump it up quite a bit.

The computer is applying voltage to the valve when it needs to, so when there isn't any, there is a vacuum leak.

EGR isn't applied all the time, so it has to be the valve ???

There are all sorts of videos and posts on how to check the voltage from the PCM, but nothing on how the vacuum ports work with or with out voltage.

Do you know how the Vacuum Regulator Solenoid is supposed to work concerning the vacuum.

I cleaned it (it was very dirty) and it made no difference.

Here is how mine is working:

I apply vacuum (with a vacuum pump) to the bottom port where there would normally be manifold vacuum.

I plug off the top port and apply vacuum and it holds nothing _ I can here the breather at the top of the valve where the dust filter is letting in vacuum.

Is it supposed to do that ?

That would cause the leak, that's for sure.

If I apply 12 volts to the solenoid and do the procedure as above, then it will hold vacuum reasonably well (reasonably well meaning that it will leak down with in a number of seconds), but it won't hold it for more then a minute if I pump it up quite a bit.

The computer is applying voltage to the valve when it needs to, so when there isn't any, there is a vacuum leak.

EGR isn't applied all the time, so it has to be the valve ???

There are all sorts of videos and posts on how to check the voltage from the PCM, but nothing on how the vacuum ports work with or with out voltage.

#16

The 3 port EGR vacuum modulators, EVR's(solenoids, lol) have 2 of the ports connected to Vacuum sources I thought, and 1 connected to EGR valve.

But new EGR solenoid for 1999 Ranger or Mazda 3.0l is 2 port, so ????

Not sure why that is, the two separate vacuums sources.

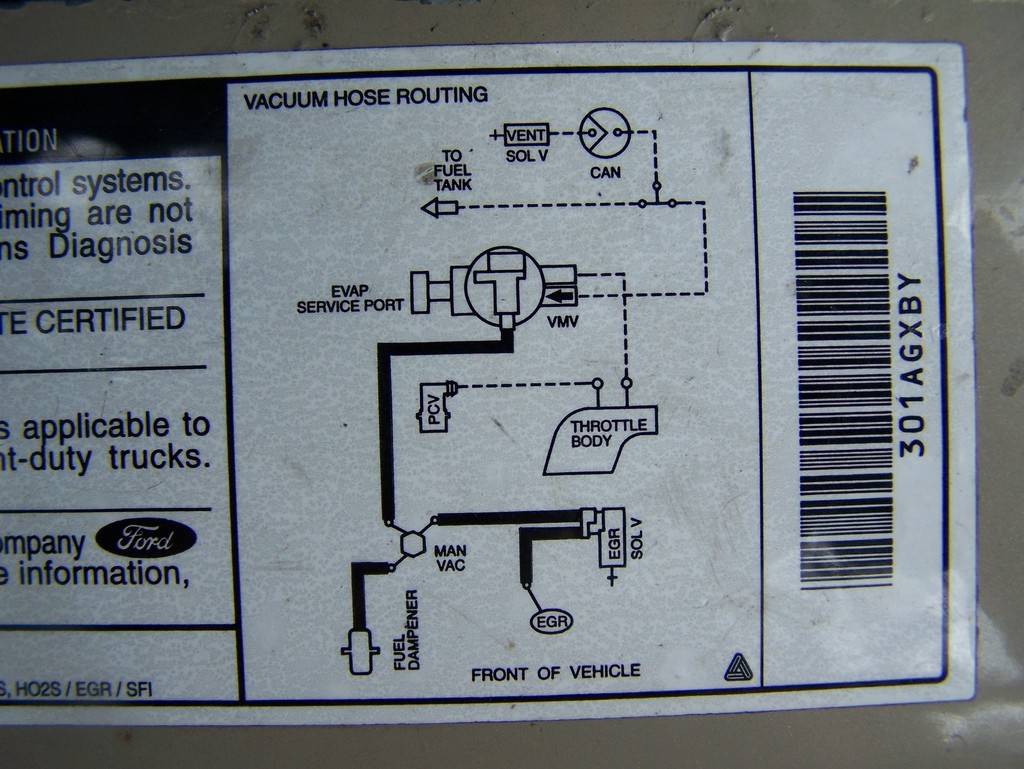

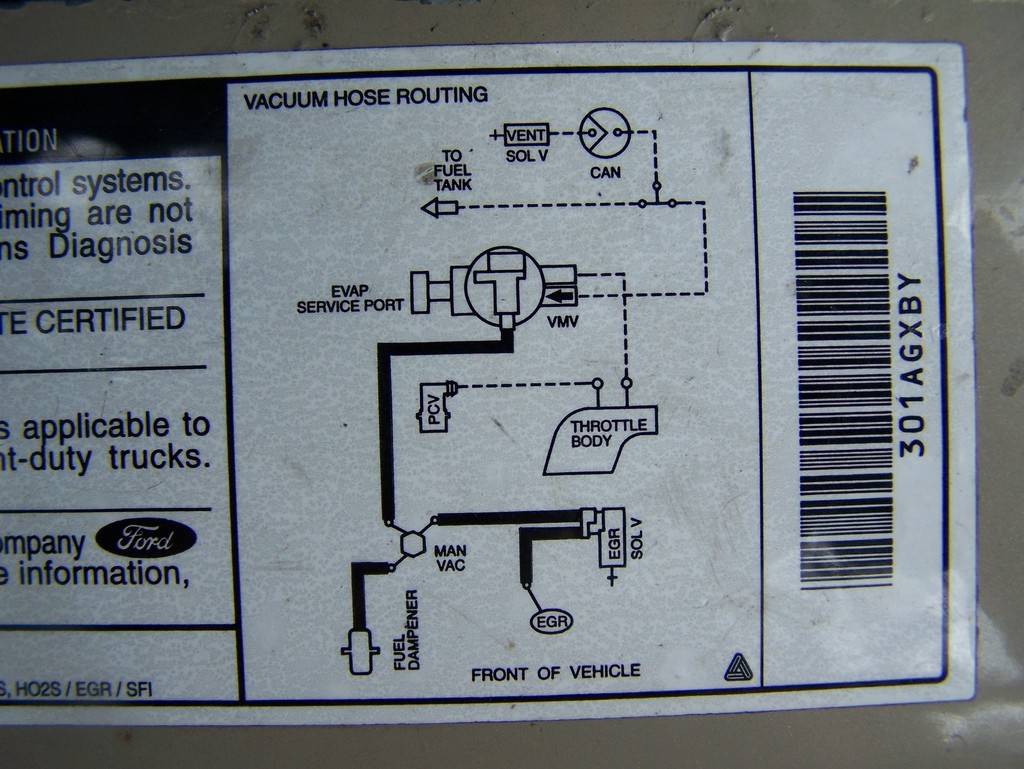

All the vacuum diagrams I have seen only show the 2 hoses connected, even on '99, look at your vacuum diagram on the rad support, see what it shows for the "EVR"

Exhaust gas recirculation(EGR) was added to reduce NOx emissions which spike very high when cylinders get too hot.

Cylinders get hotter when under load, and NOx spikes very fast at that time.

When exhaust gases are added to richer air/fuel mixes it slows down the burn which has a tendency to burn too fast being richer so heats up the cylinders.

So any extra power just goes to radiator, lol, and NOx goes up.

EGR system doesn't take away power, it simply keeps cylinders running without the extreme heat from being under load.

Secondary effect is less chance of pinging/knocking, which is caused by lower octane fuels self-igniting from the heat of compression and cylinder temps.

So EGR system is not used/needed on cold engines, and is used when engine is warmed up and under load.

"under load" is determined by the computer as programmed at the factory to meet emissions requirements for NOx levels.

Some engines never needed EGR systems, but most have them now since it was also found that running cylinders cooler lowers efficiency, MPG, which is why 195degF thermostats are used now instead of the 180degF back the the 1970's

So there is a narrow range of "best" cylinder temps.

Gasoline engines are only about 25% efficient, that means that if a gallon of gas costs $4 then $1 goes to moving you down the road and $3 goes out the radiator as heat, depressing isn't it, lol

Diesels are 33% efficient.

But they are getting better, both gas and diesel, 30% for gas and 38% for diesel, but still depressing, lol.

In fairness 5% is lost in friction of all the moving parts, but thats just another form of heat IMO

NOx = Nitrogen Oxides are a family of poisonous, highly reactive gases. These gases form when fuel is burned at high temperatures

But new EGR solenoid for 1999 Ranger or Mazda 3.0l is 2 port, so ????

Not sure why that is, the two separate vacuums sources.

All the vacuum diagrams I have seen only show the 2 hoses connected, even on '99, look at your vacuum diagram on the rad support, see what it shows for the "EVR"

Exhaust gas recirculation(EGR) was added to reduce NOx emissions which spike very high when cylinders get too hot.

Cylinders get hotter when under load, and NOx spikes very fast at that time.

When exhaust gases are added to richer air/fuel mixes it slows down the burn which has a tendency to burn too fast being richer so heats up the cylinders.

So any extra power just goes to radiator, lol, and NOx goes up.

EGR system doesn't take away power, it simply keeps cylinders running without the extreme heat from being under load.

Secondary effect is less chance of pinging/knocking, which is caused by lower octane fuels self-igniting from the heat of compression and cylinder temps.

So EGR system is not used/needed on cold engines, and is used when engine is warmed up and under load.

"under load" is determined by the computer as programmed at the factory to meet emissions requirements for NOx levels.

Some engines never needed EGR systems, but most have them now since it was also found that running cylinders cooler lowers efficiency, MPG, which is why 195degF thermostats are used now instead of the 180degF back the the 1970's

So there is a narrow range of "best" cylinder temps.

Gasoline engines are only about 25% efficient, that means that if a gallon of gas costs $4 then $1 goes to moving you down the road and $3 goes out the radiator as heat, depressing isn't it, lol

Diesels are 33% efficient.

But they are getting better, both gas and diesel, 30% for gas and 38% for diesel, but still depressing, lol.

In fairness 5% is lost in friction of all the moving parts, but thats just another form of heat IMO

NOx = Nitrogen Oxides are a family of poisonous, highly reactive gases. These gases form when fuel is burned at high temperatures

Last edited by RonD; 07-15-2016 at 02:57 PM.

#17

Here's the diagram, it's pretty simple.

There's one main vacuum line from the intake manifold that goes to the EGR solenoid valve (which is controlled by the computer based upon the instructions from the DPFE sensor)

From the Solenoid valve the vacuum reaches its end at the actual EGR valve.

I totally disconnected the vacuum line from the solenoid valve and off course there was a big vacuum leak.

I drove it that way just to see what would happen and it didn't have that annoying jerk.

So I connected the vacuum line(s) back up and it didn't do it this time.

Maybe cleaning the valve did some good and the computer just has to learn the valve is functioning properly ???

I'll drive it around for a few days and see if it stays fixed.

I tested the new valve with the vacuum pump and it behaved the same as my old one, so it's staying at the auto parts store for now _ they want 50 bucks for it. Hmmph...

I guess I just have to give it some time.

EDIT:

What I think is happening is that the DPFE sensor is malfunctioning, I don't think it's defective, but just dirty.

It's sending false information back to the PCM and in turn the EGR vacuum solenoid is operating sporadically causing vacuum fluctuations.

This in turn is causing the slight jerking/surging while driving.

This would also explain that when I unplug the voltage source from the vacuum solenoid, the jerking stops.

It looks like the DPFE sensor has been in there since day one, its cover is oxidized and powdery indicating that it's been in there for many years.

Would you agree with this theory ?

There's one main vacuum line from the intake manifold that goes to the EGR solenoid valve (which is controlled by the computer based upon the instructions from the DPFE sensor)

From the Solenoid valve the vacuum reaches its end at the actual EGR valve.

I totally disconnected the vacuum line from the solenoid valve and off course there was a big vacuum leak.

I drove it that way just to see what would happen and it didn't have that annoying jerk.

So I connected the vacuum line(s) back up and it didn't do it this time.

Maybe cleaning the valve did some good and the computer just has to learn the valve is functioning properly ???

I'll drive it around for a few days and see if it stays fixed.

I tested the new valve with the vacuum pump and it behaved the same as my old one, so it's staying at the auto parts store for now _ they want 50 bucks for it. Hmmph...

I guess I just have to give it some time.

EDIT:

What I think is happening is that the DPFE sensor is malfunctioning, I don't think it's defective, but just dirty.

It's sending false information back to the PCM and in turn the EGR vacuum solenoid is operating sporadically causing vacuum fluctuations.

This in turn is causing the slight jerking/surging while driving.

This would also explain that when I unplug the voltage source from the vacuum solenoid, the jerking stops.

It looks like the DPFE sensor has been in there since day one, its cover is oxidized and powdery indicating that it's been in there for many years.

Would you agree with this theory ?

Last edited by Jeff R 1; 07-16-2016 at 10:47 AM.

#18

hello

I am new to this forum as I have acquired a 1999 ranger xl 3.0 recently

I am having a similar problem. Truck seems to run fine and accelerates ok but when it shifts into 3rd gear or overdrive it starts to shake pretty bad. If I let off the gas or floor it it smooths out somewhat but if I try and just drive normally it shakes so bad I feel it might fly apart!

could I be having the same issue? the truck has 102k miles and I replaced the plugs, wires, air and fuel filters. i guess egr and pcv are next

I am new to this forum as I have acquired a 1999 ranger xl 3.0 recently

I am having a similar problem. Truck seems to run fine and accelerates ok but when it shifts into 3rd gear or overdrive it starts to shake pretty bad. If I let off the gas or floor it it smooths out somewhat but if I try and just drive normally it shakes so bad I feel it might fly apart!

could I be having the same issue? the truck has 102k miles and I replaced the plugs, wires, air and fuel filters. i guess egr and pcv are next

#19

On mine, my MAF sensor was really dirty too. There is a special cleaner for that.

The sensor is very fragile, some use Q-Tips, but apparently you're not even supposed to use that.

The special cleaner leaves no residue, anything else is not supposed to work _ so I have been told.

My synchronizer was also installed wrong (it was running like that for years). It was more then 90 degrees out, from the reference setting at number one at TDC (compression) using the proper OTC alignment tool. The Ford dealer actually let me borrow theirs over night !

I'm also leaning towards the DPFE sensor.

What seems to happen to them is that the hot gasses and carbon eventually break the seal on the inside and the electronics become compromised.

I also cleaned the connections on the PCM and the ground next to its connection was loose. Mine sat for 8 years in a car port so I went through and cleaned all the engine bay connections as well.

I think I read in your other post that yours is an auto, so maybe there is something different going on there.

Did you check your EGR valve with a vacuum pump, throwing parts at a problem and guessing/hoping that it may be cured is not the way to go.

I also went through and checked my vacuum line harness that runs behind the engine. I physically removed it, plugged off all the ports and applied vacuum with my pump.

After I determined that it was OK, I started connecting up systems, 1 by 1 until my problem surfaced.

It just happened to be that when I connected up the EGR valve solenoid that the jerking symptom reappeared.

My valve solenoid was vey dirty, I cleaned that and there wasn't really any change and the valve itself looked quite new, so I don't believe it was the problem.

The only thing left in the EGR system that fails is the DPFE sensor, so that's my next step.

You also mentioned a PCV valve, does it even have one, all there seems to be on mine is a line that runs off where the oil filler cap is that connects into the main air flow tube ?

There doesn't appear to be any valve at all, the gasses from the engine just flow into the throttle body tube.

There will be a seal on the dip stick, make sure that's in good shape.

The sensor is very fragile, some use Q-Tips, but apparently you're not even supposed to use that.

The special cleaner leaves no residue, anything else is not supposed to work _ so I have been told.

My synchronizer was also installed wrong (it was running like that for years). It was more then 90 degrees out, from the reference setting at number one at TDC (compression) using the proper OTC alignment tool. The Ford dealer actually let me borrow theirs over night !

I'm also leaning towards the DPFE sensor.

What seems to happen to them is that the hot gasses and carbon eventually break the seal on the inside and the electronics become compromised.

I also cleaned the connections on the PCM and the ground next to its connection was loose. Mine sat for 8 years in a car port so I went through and cleaned all the engine bay connections as well.

I think I read in your other post that yours is an auto, so maybe there is something different going on there.

Did you check your EGR valve with a vacuum pump, throwing parts at a problem and guessing/hoping that it may be cured is not the way to go.

I also went through and checked my vacuum line harness that runs behind the engine. I physically removed it, plugged off all the ports and applied vacuum with my pump.

After I determined that it was OK, I started connecting up systems, 1 by 1 until my problem surfaced.

It just happened to be that when I connected up the EGR valve solenoid that the jerking symptom reappeared.

My valve solenoid was vey dirty, I cleaned that and there wasn't really any change and the valve itself looked quite new, so I don't believe it was the problem.

The only thing left in the EGR system that fails is the DPFE sensor, so that's my next step.

You also mentioned a PCV valve, does it even have one, all there seems to be on mine is a line that runs off where the oil filler cap is that connects into the main air flow tube ?

There doesn't appear to be any valve at all, the gasses from the engine just flow into the throttle body tube.

There will be a seal on the dip stick, make sure that's in good shape.

Last edited by Jeff R 1; 07-17-2016 at 10:41 AM.

#20

I did this test to the DPFE sensor and it failed.

Voltage stayed at 1.8 volts with the EGR valve opened or closed.

The reference voltage is correct at 5 volts, so at least the PCM and ground is good.

http://easyautodiagnostics.com/ford/...e-egr-system-3

I'm not surprised it was faulty, it was checked by the Mazda dealer 8 years ago after it threw up a code.

The Mazda dealer cleared the code and as far as I can tell, it was never replaced.

The paper work shows an estimate of the repair and cost of the new sensor, but it looks like the work was never carried out.

Being a city truck I'm sure the old guy who drove it didn't drive it far, so he didn't bother.

Voltage stayed at 1.8 volts with the EGR valve opened or closed.

The reference voltage is correct at 5 volts, so at least the PCM and ground is good.

http://easyautodiagnostics.com/ford/...e-egr-system-3

I'm not surprised it was faulty, it was checked by the Mazda dealer 8 years ago after it threw up a code.

The Mazda dealer cleared the code and as far as I can tell, it was never replaced.

The paper work shows an estimate of the repair and cost of the new sensor, but it looks like the work was never carried out.

Being a city truck I'm sure the old guy who drove it didn't drive it far, so he didn't bother.

Last edited by Jeff R 1; 07-20-2016 at 09:44 PM.

#21

I replaced the EGR Pressure sensor today (DPFE sensor) and that seems to have cured the problem.

I took the old metal one apart and the seals were in good condition, but what happened was that the metal had corroded around the seals allowing moisture to come in contact with the circuit board.

The water also rusted areas that were not made of aluminum, further adding to the mess and corrosion of the unit.

The rusty water also did a very good job of shorting out the circuit board.

Surprisingly it was very clean in there where the pressure chambers were hooked up to the EGR tubes, so in case any one is wondering about cleaning the internals, don't waste your time, there's nothing there to clean.

Where did the water come from, when fossil fuels are burned, water is created in the exhaust, this water also makes its way as vapor condensing on the cold metal on a cold engine inside the sensor.

When the engine fully warms up I would think that the vapor doesn't condense anymore, but for city driving and short runs, it would be very bad for a metal unit _ probably why they are made out of plastic now.

See this post on pricing of the DPFE sensor.

https://www.ranger-forums.com/genera...us-off-148781/

And not to forget, a big thanks to Ron for helping me figure this out !

I took the old metal one apart and the seals were in good condition, but what happened was that the metal had corroded around the seals allowing moisture to come in contact with the circuit board.

The water also rusted areas that were not made of aluminum, further adding to the mess and corrosion of the unit.

The rusty water also did a very good job of shorting out the circuit board.

Surprisingly it was very clean in there where the pressure chambers were hooked up to the EGR tubes, so in case any one is wondering about cleaning the internals, don't waste your time, there's nothing there to clean.

Where did the water come from, when fossil fuels are burned, water is created in the exhaust, this water also makes its way as vapor condensing on the cold metal on a cold engine inside the sensor.

When the engine fully warms up I would think that the vapor doesn't condense anymore, but for city driving and short runs, it would be very bad for a metal unit _ probably why they are made out of plastic now.

See this post on pricing of the DPFE sensor.

https://www.ranger-forums.com/genera...us-off-148781/

And not to forget, a big thanks to Ron for helping me figure this out !

Last edited by Jeff R 1; 07-20-2016 at 09:43 PM.

Thread

Thread Starter

Forum

Replies

Last Post

mad87

Drivetrain Tech

45

08-06-2020 02:12 AM

![Chef[1]](https://www.ranger-forums.com/rf/forum2/images/smilies/chef[1].gif)