crosspin problems (56k no)

#1

crosspin problems (56k no)

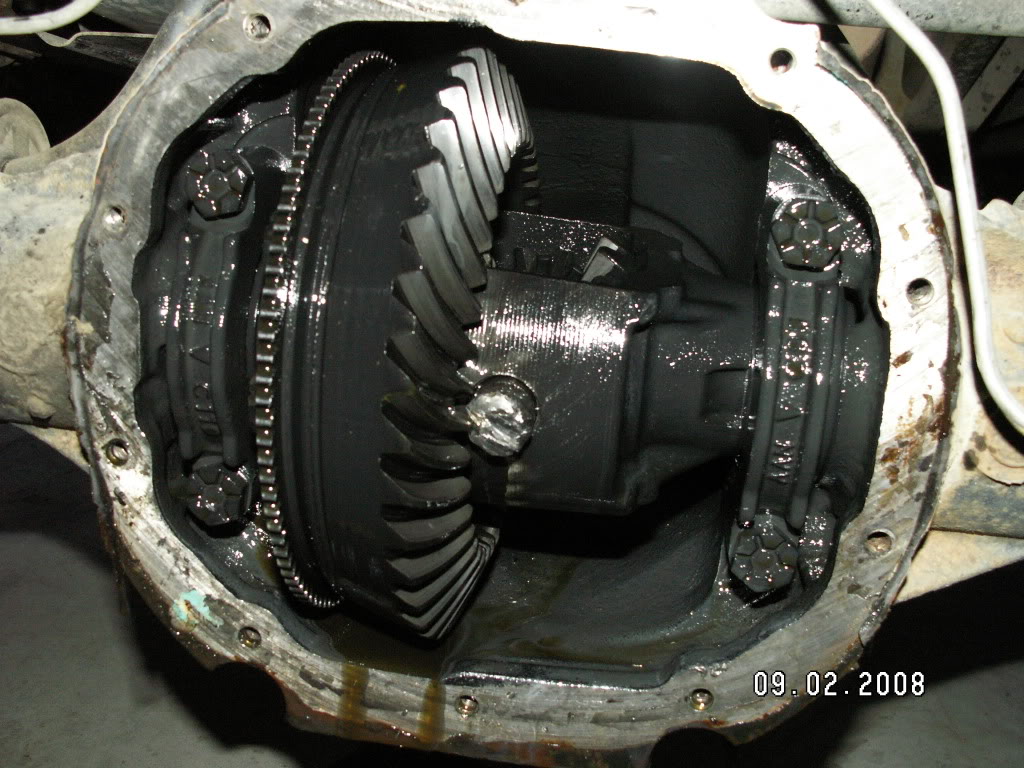

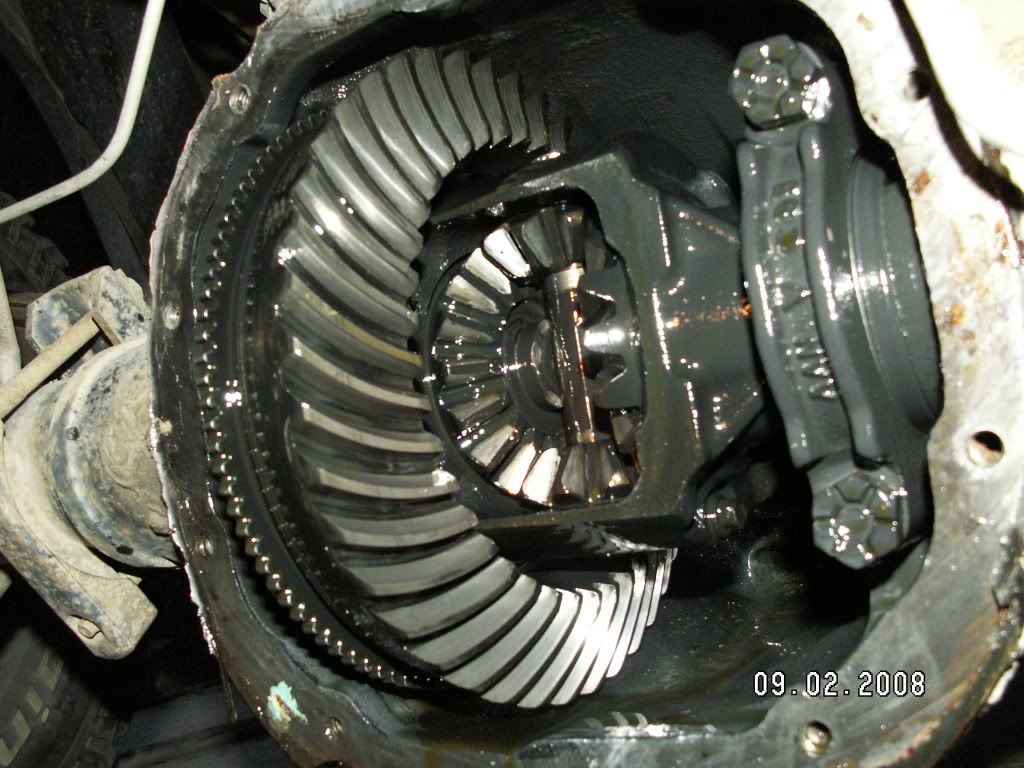

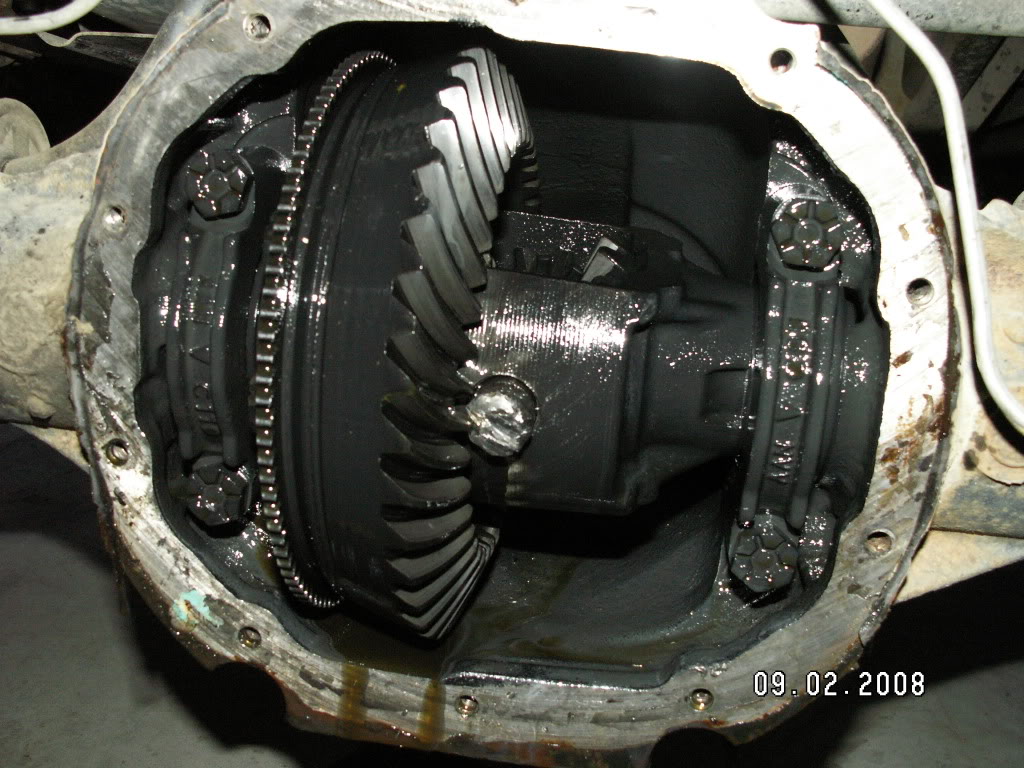

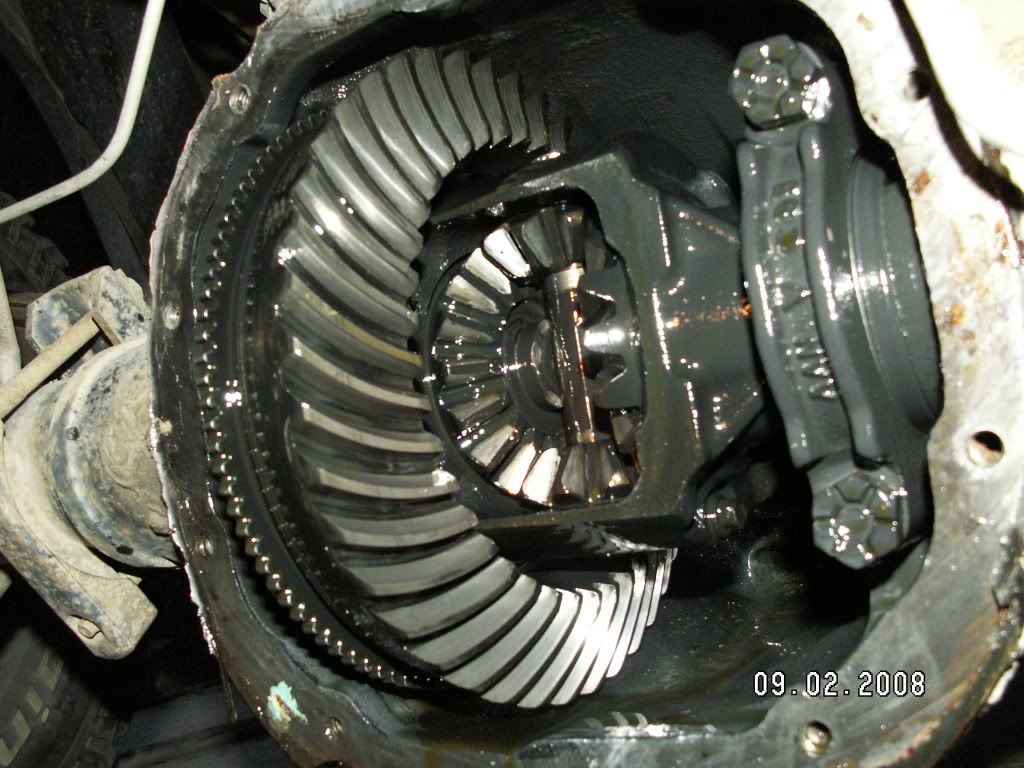

ok so last weekend i took the truck up to some local mountains and was pushin the truck pretty hard. well on the drive home i started hearing this clunk at random times....somtimes when i hit the brakes, when i pushed in the clutch, when i gave or let off the gas and somtimes when i was just driving at a constant speed and throttle it would do it. so ive been driving it for the last couple of days cause i couldnt figure out where it was happening from...couldnt tell if it was the t-case or the rear or front end...and since it was so random i couldnt listen for it. so today i jacked up the rear end and put it in 1st and let it spin and went out and listened to it...definatly some clunking coming from the rear end. so i pull the inspection cover off and look around. firs thing i notice it that the cross pin is all chewed up (from hitting the ring gear)...then i scoop out the botton of the pan...i get a bounch of shaving and about 5 or 6 pieces of metal a little bigger than a BB. so i spin it around and none of the teeth are messed up at all. then i look at the other side of the cross pin..i notice it is loose and there is a crack going through it...so i pulled the bolt that holds it in, out. then i pull the 2 pieces out and try to then push the rest of the pin out...but it cant go out the side thats mauled up cause it hits the ring gear...its notched on the side that broke so im assuming it is supposed to come out that side...but it wont come out..i think it might be cause the other side is to mauled to fit through the hole....any way what to u think...why do u think it broke..is somthing else messed up do u think, could i just put a new cross pin in and call it good for a wile..at least until i get my 8.8? thanks

pix (sorry some are crappy cause it was dark out)

pix (sorry some are crappy cause it was dark out)

#2

You're geared aren't you? It looks like the ring gear is nice and fat as heck like a .56 or a .88 gear. Certainly not a Ford 4.10 ring gear. You've got a notched crosspin because you cannot get the crosspin out without mods to the ring. only way to get it out is to grind the ring gear teeth down on a few teeth. I had to do it on my .88 teeth to install my aussie.

Center pin is notched so that you can rotate it to install the c-clips without completely removing the center pin. The crosspin is installed BEFORE the ringgear is installed.

Most importantly, you need to see what else took a dump in there. How are those spider and side gears?

Center pin is notched so that you can rotate it to install the c-clips without completely removing the center pin. The crosspin is installed BEFORE the ringgear is installed.

Most importantly, you need to see what else took a dump in there. How are those spider and side gears?

#4

#5

#9

#10

noob! the crosspin is what keeps the axle shafts spread apart and also keeps the c-clips in place. in other words, if the crosspin/center shaft takes a dump on you, you could potentially have an axle shaft move inward, release a c-clip, then you'll have a flying axleshaft complete with drum and wheel/tire on your hands.

#12

#15

I'd get one from Randy's...

Randy's Ring & Pinion. The Differential Experts. Auto Parts & Services.

BUT....WHAT caused the center pin to do this in the first place??

Randy's Ring & Pinion. The Differential Experts. Auto Parts & Services.

BUT....WHAT caused the center pin to do this in the first place??

#16

#17

#18

Join Date: Jan 2005

Location: West Topsham, VT

Posts: 1,709

Likes: 0

Received 0 Likes

on

0 Posts

The cross pin is more than just a spacer for the shafts and c clips, it transfers power from the carrier spiders to the shaft spiders to the shafts. Notched pins tend to fail due to the material removed, as yours did on the retainer bolt side.

That part cracked (from wheeling probably), allowing it to slide out the other side and get mangled by the ring. It looks like the carrier is cracked at the retaining bolt, but that may be the pic, I can't tell. It's probably a good thing it did not slide out, as that would have stopped you REAL fast!

I assume that mangled end is what is stopping you form pushing it back out? Can you get an oxy acetylene torch to cut that end? Or grind it to fit through the carrier hole?

Can you fit the pin out far enough to clear a spider? If so, try to spin the shafts to walk the spider out, that might give you some more room to work on it.

That part cracked (from wheeling probably), allowing it to slide out the other side and get mangled by the ring. It looks like the carrier is cracked at the retaining bolt, but that may be the pic, I can't tell. It's probably a good thing it did not slide out, as that would have stopped you REAL fast!

I assume that mangled end is what is stopping you form pushing it back out? Can you get an oxy acetylene torch to cut that end? Or grind it to fit through the carrier hole?

Can you fit the pin out far enough to clear a spider? If so, try to spin the shafts to walk the spider out, that might give you some more room to work on it.

#19

yea i got it through but it wont come out cause only the part thats notched could clear the ring gear..after that it doesnt fit...so now i guess i have to grind the ring gear...or would it be easyer to pull the hole thing? also if i grind it what precautions should i do..im thinking stuff full of rags and put a big shop magnet by the bottom of the diff. also witch side should i grind...the side with the retaining bolt or the other? thanks

#20

#22

#24

Grind away on the INSIDE of the ring....don't go too deep into the height of the teeth, don't go too deep into the area where the teeth mesh... I wouldn't suggst using a 4.5" grinder....but my dremel took a dump on me when just starting to trim it, so I had to work with what I had(4.5" grinder with 80 grit flap wheel). Don't get the ring gear too hot...small bits at a time. Don't worry about metal dust in your diff....spray brake cleaner on everything you can to get the dust in the bottom of the diff, then either soak it up or get a big magnet to pull the metal out of the 'valley' that may or may not be filled iwth oil still....then change the fluid like 50miles after you do your work in the axle. The plug is magnetic and it'll pick up the metal particles.

https://www.ranger-forums.com/forum2...tease-4-a.html

https://www.ranger-forums.com/forum2...tease-4-a.html