Building traction bars.

#1

Building traction bars.

My dad and I are building some traction bars for my truck. They are the over leaf style like the James Duff bars. One side is finished and I should have the other side welded up by tonight. We have 100% argon in the welder for when we build intercooler plumbing(aluminium) on my other truck, so it is welding like crap with steel.

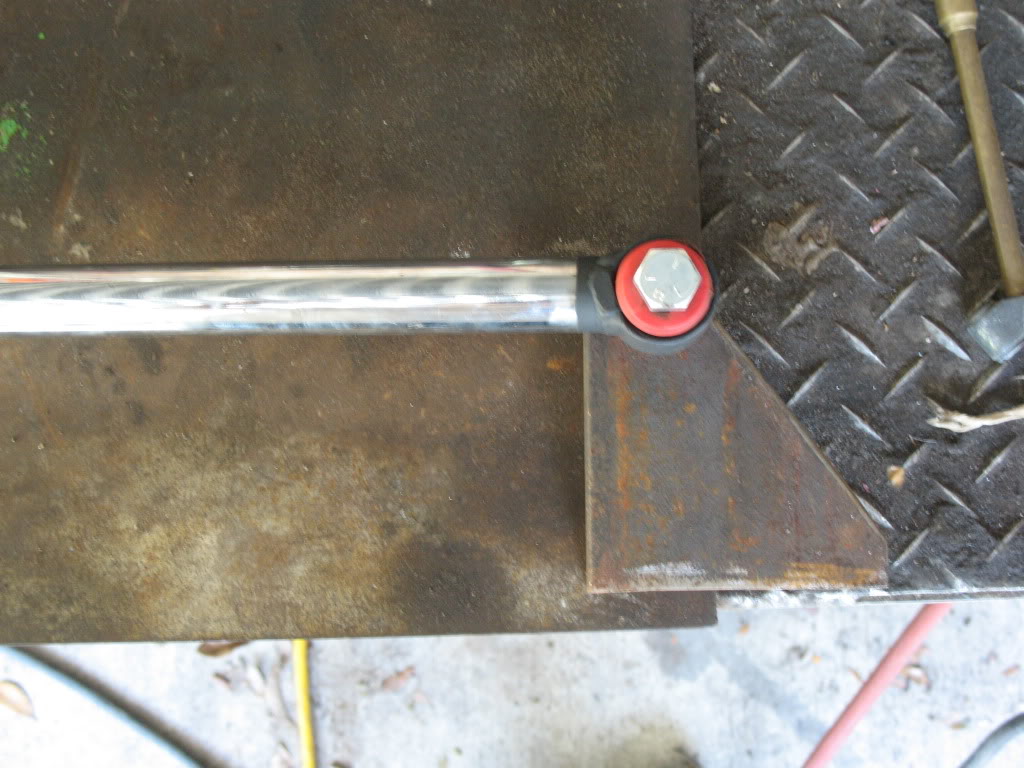

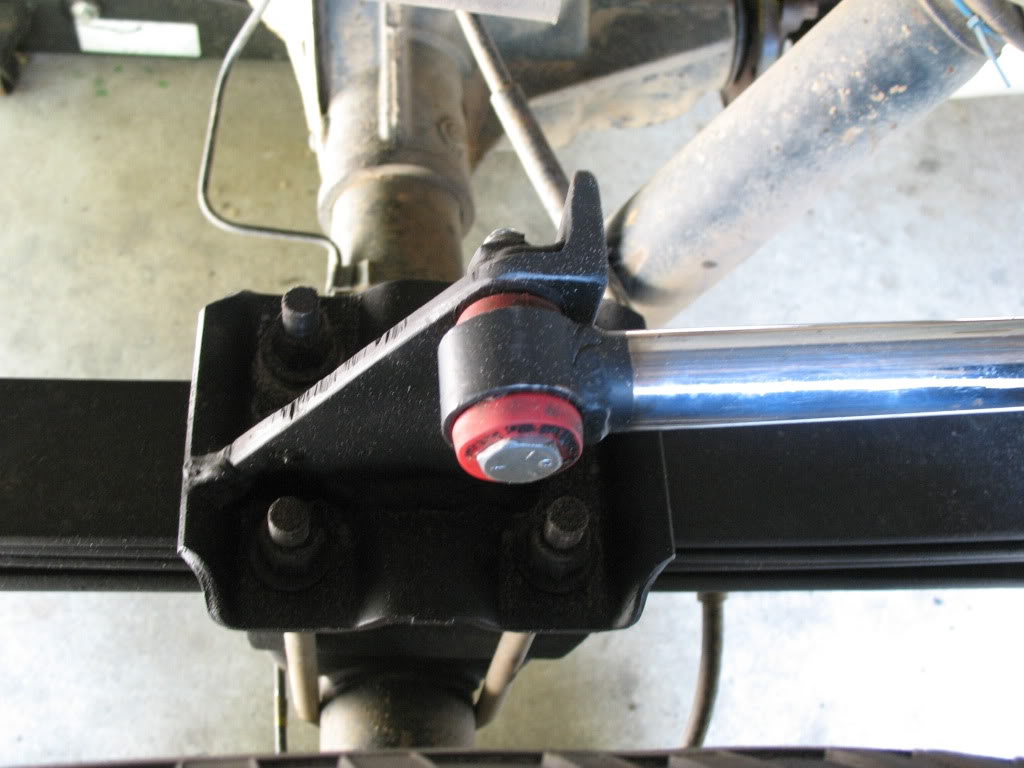

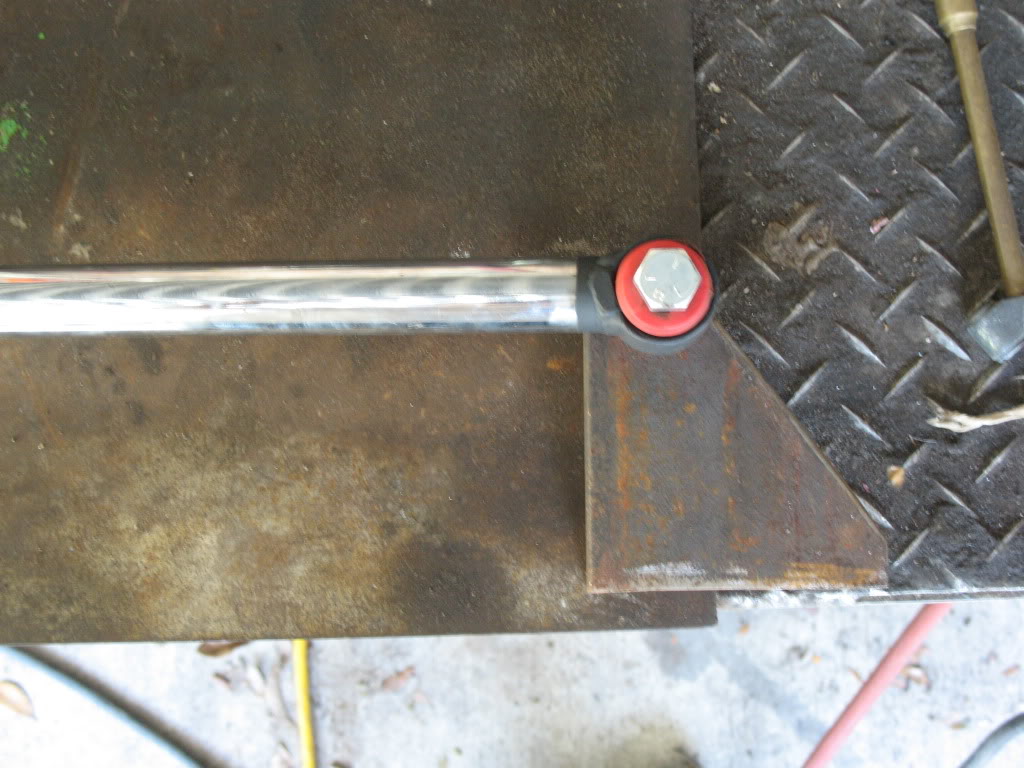

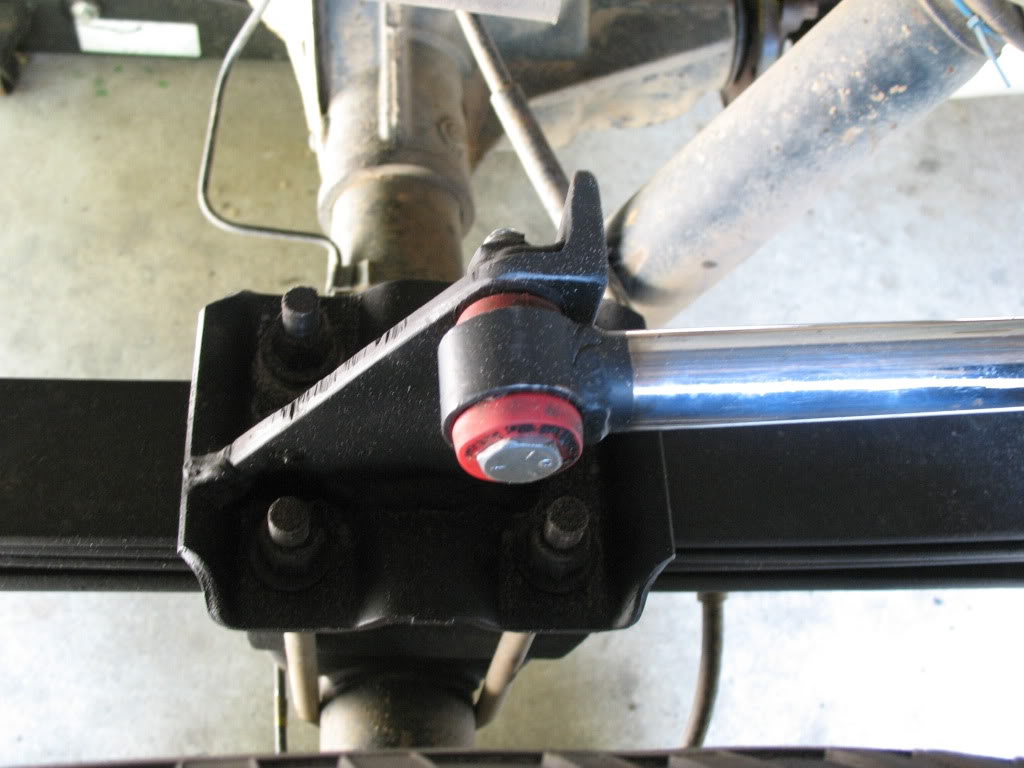

Anyway, here are a few blurry pictures:

Phone:

Anyway, here are a few blurry pictures:

Phone:

#3

#4

Thanks.

I was looking at building something like this:

But there was the whole welding to cast thing unless I built a truss. Not that that would be a bad Idea, this design just seems simpler.

Me too, I am taking it out tonight when we finish to see how it does. If it can't handle the abuse we will try something different. Ha, it's not like I am out anything.

#6

#8

#9

#11

they will work fine. theyre pretty much a copy of these: (which have been on the market for years... tons of people have them and theyre flawless.)

Ford Bronco II, Ranger, Traction Bars, Long Link Traction Bars

Ford Bronco II, Ranger, Traction Bars, Long Link Traction Bars

#12

#13

I think that front mount is too beefy to bend and the bushings there are too thin to allow for much flex. It'll flex, but it'll take the front bushings out with it I'd think. The duff front brackets on mine are way bent...just like how they come for the 97 and older trucks.

Did a good job Chris. Beef. I plan on replacing my duff's with a ladder type bar....but not wanting to cut up my dual tailpipes.

Did a good job Chris. Beef. I plan on replacing my duff's with a ladder type bar....but not wanting to cut up my dual tailpipes.

#14

Those front bushings are the biggest thing I am worried about. I don't think they will last long.

Thanks man. I would rather have ladder bars, but I don't want to loose my ground clearance. I'm sure I could build them without loosing a whole lot though. If these don't work out I can always try something different.

Thanks man. I would rather have ladder bars, but I don't want to loose my ground clearance. I'm sure I could build them without loosing a whole lot though. If these don't work out I can always try something different.

#15

This is me not even fully flexed out with my 33', shackles, and you can see my Traction bar there above the axle.. works just fine :-D

This is me not even fully flexed out with my 33', shackles, and you can see my Traction bar there above the axle.. works just fine :-D

#17

Thanks.

Sorry no pictures of the truck, it was dark and I only had my phone. I had to unbolt the bedside braces so they didn't get mangled by the bar at full bump. I just need to remount it somewhere else.

Everything worked good so far, handles great and nothing broke. I will through the BFGs back on tomorrow and see how it handles on the road.

Sorry no pictures of the truck, it was dark and I only had my phone. I had to unbolt the bedside braces so they didn't get mangled by the bar at full bump. I just need to remount it somewhere else.

Everything worked good so far, handles great and nothing broke. I will through the BFGs back on tomorrow and see how it handles on the road.

#18

Hey Chris...

On this area:

Put a washer on the bolt on the outside of the bushing there - will help to compress it and keep it in a godo angle - looks like yoru bolt will tear through the bushing in a heartbeat if you do a few sets of flexes on the bumps - They look great man..

Oh, also - use a grade 8 bolt - if I'm right.. that one is only a Grade 5 with the 3 hashes - Probably be alot safer to use for that section of the trac bar :-D

Any idea what the end cost was on materials? I know that paying $99 for the JD Trac Bars is a most excellent price

On this area:

Put a washer on the bolt on the outside of the bushing there - will help to compress it and keep it in a godo angle - looks like yoru bolt will tear through the bushing in a heartbeat if you do a few sets of flexes on the bumps - They look great man..

Oh, also - use a grade 8 bolt - if I'm right.. that one is only a Grade 5 with the 3 hashes - Probably be alot safer to use for that section of the trac bar :-D

Any idea what the end cost was on materials? I know that paying $99 for the JD Trac Bars is a most excellent price

#19

I plan on it. I just didn't have the right size because I used them on the other side. After seeing that picture I will do it today.

I was going to use grade 8, but again, I didn't have one at the time. The front bolt is grade 8.

Freeeeeeee!!!!! I have a lot of scrap metal from other projects and such. I wouldn't have used the chrome tubing for the bar, but it was all I had that size besides stainless and I didn't want to use my stainless.

I wouldn't mind paying the $100 if I couldn't make them for free. lol

Thanks man.

I was going to use grade 8, but again, I didn't have one at the time. The front bolt is grade 8.

Freeeeeeee!!!!! I have a lot of scrap metal from other projects and such. I wouldn't have used the chrome tubing for the bar, but it was all I had that size besides stainless and I didn't want to use my stainless.

I wouldn't mind paying the $100 if I couldn't make them for free. lol

Thanks man.

#20

#21

#22

If you are still getting axle wrap then there has to be another problem, like the tubing wall thickness is too small allowing the tube to flex otherwise the design should work.

#24

Adding a another side to the axle mount could help out in the bushing area, not only in twist but the extra brkt will hold the bushings together and let then work as a pair.

If you are still getting axle wrap then there has to be another problem, like the tubing wall thickness is too small allowing the tube to flex otherwise the design should work.

If you are still getting axle wrap then there has to be another problem, like the tubing wall thickness is too small allowing the tube to flex otherwise the design should work.

#25

How about using a longer bolt for the diff end and add a nut/washer inside of the bushing ?

Not sure of the distance you have to play with but by sort of tightening the bolt/nut to the bracket, then adding a large washer, the shock w/ bushings, another washer and a locking nut (which you can get in a grade 8, metal nut, not the fiber ones and no split lock washers).

The locking nut will allow you to tighten the shock without squashing the bushings and stopping when you think it is tight and not worrying if it will loosen up.

And get a bolt that is long enough to handle the whole package.

Sorry if this seems like I am pushing you to do something that you don’t think is correct but I tend to speak my mind.

Luck,

Not sure of the distance you have to play with but by sort of tightening the bolt/nut to the bracket, then adding a large washer, the shock w/ bushings, another washer and a locking nut (which you can get in a grade 8, metal nut, not the fiber ones and no split lock washers).

The locking nut will allow you to tighten the shock without squashing the bushings and stopping when you think it is tight and not worrying if it will loosen up.

And get a bolt that is long enough to handle the whole package.

Sorry if this seems like I am pushing you to do something that you don’t think is correct but I tend to speak my mind.

Luck,