sliders.. FINALLY!

#1

sliders.. FINALLY!

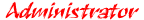

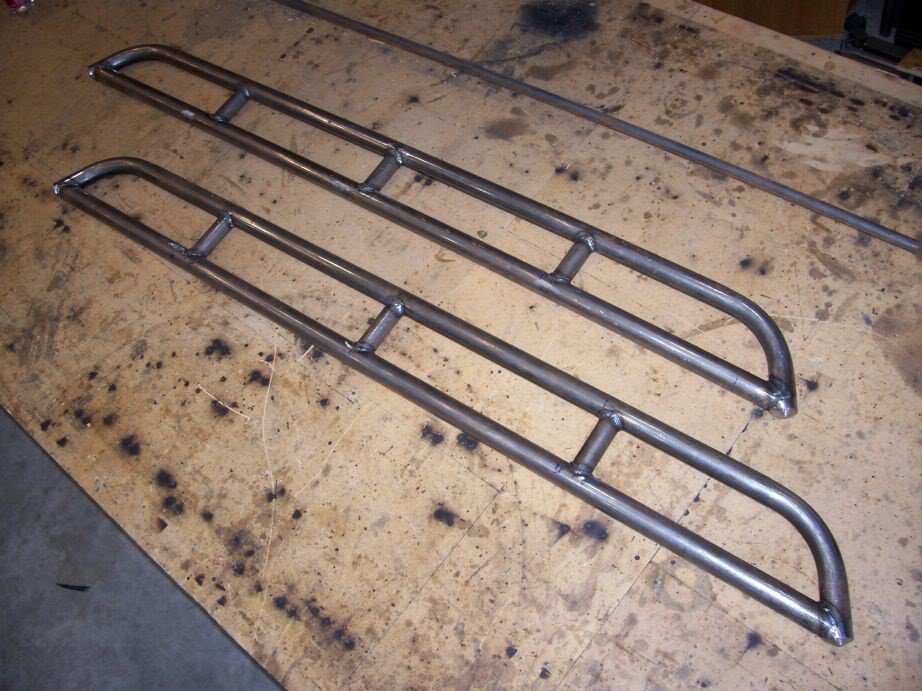

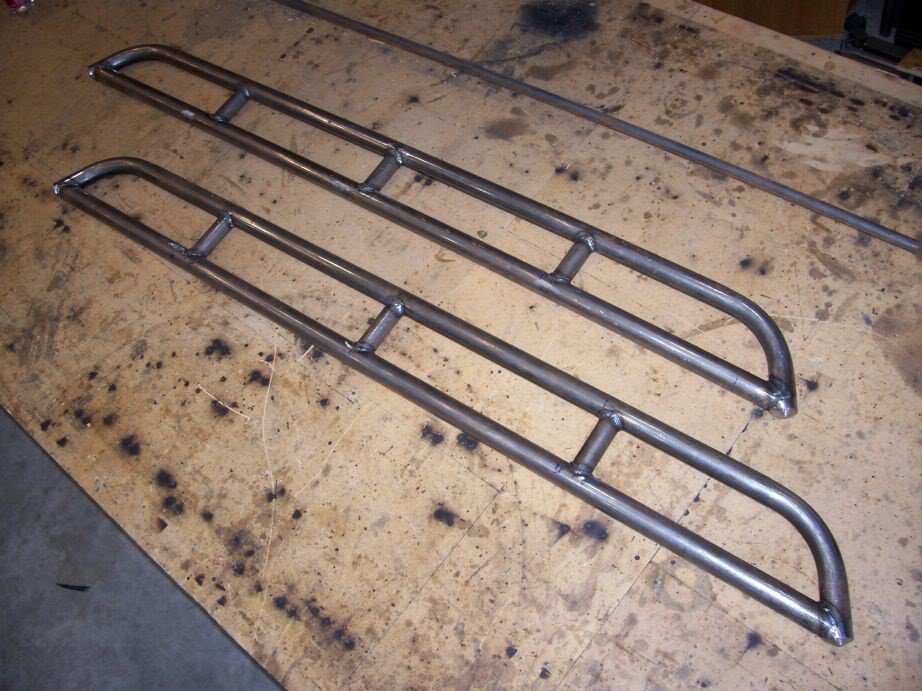

Well, I've had the material around for awhile and just have had bigger fish to fry on my truck. I changed my design slighty after seeing Jason do a set. I originally had 'em similar to Zach's, then changed 'em abit as you can see.

I plan to mount 'em this weekend. I'll have updates as I go..

I plan to mount 'em this weekend. I'll have updates as I go..

#2

#14

The angle on the top tube is ~60*.. while the distance you ask of I believe is in the neighborhood of 4-1/2 to 5". Hopefully the mounting goes smoothly tomorrow. I have abit of

a different technique in mind, so I will be sure to post as detailed pics as possible!

Not so much that as they are one of the few remaining 'big' fabrication products that I never really got going on. But its damn ironic timing still!

Last edited by 2002FX4; 04-12-2008 at 10:47 PM.

#20

HREW? Hot Rolled Electric Welded?

I used Cold Rolled Electric Welded on my sliders. Now hoops and other vital stuff DOM.

Still look good I am not sure that I have heard of HREW.

Nothing wrong with CREW several guys around these parts make complete chassis modifieds and other circle dirt track cars out of CREW. Only thing is to watch the Seam and how you bend it. They are regulated to use DOM on the driver cage though.

I used Cold Rolled Electric Welded on my sliders. Now hoops and other vital stuff DOM.

Still look good I am not sure that I have heard of HREW.

Nothing wrong with CREW several guys around these parts make complete chassis modifieds and other circle dirt track cars out of CREW. Only thing is to watch the Seam and how you bend it. They are regulated to use DOM on the driver cage though.

#21

HREW? Hot Rolled Electric Welded?

I used Cold Rolled Electric Welded on my sliders. Now hoops and other vital stuff DOM.

Still look good I am not sure that I have heard of HREW.

Nothing wrong with CREW several guys around these parts make complete chassis modifieds and other circle dirt track cars out of CREW. Only thing is to watch the Seam and how you bend it. They are regulated to use DOM on the driver cage though.

I used Cold Rolled Electric Welded on my sliders. Now hoops and other vital stuff DOM.

Still look good I am not sure that I have heard of HREW.

Nothing wrong with CREW several guys around these parts make complete chassis modifieds and other circle dirt track cars out of CREW. Only thing is to watch the Seam and how you bend it. They are regulated to use DOM on the driver cage though.

#23

I didn't get nearly as far as I would have liked due to various reasons, one of which being making the sliders bolt on meant taking abit more time in the area of the mounting points. I also didn't have any long, uninterrupted stretch of time (more than about 3 hrs) at any point this weekend (I'm doing most, if not all, of my truck work at work, and there are shows/plays twice a day on the weekend and the best place to park to work is in a firelane). So between getting the tools out and cleaning up, there wasn't much time to get going full-steam. So I got the mounting points down and will mount the sliders within or by next weekend. Until then, here a a couple pics of the mounting method I chose to use:

What you see below are threaded metal inserts, aka 'weld nuts'. I did it this way so I wouldn't have to through-bolt and deal with trying to work with a nut on the inside of the frame (there are also some points where dealing with a nut on the inside would have been a real PITA). I feel this method will hold up pretty damn well, and if not, I'll just have to revisit it!

For those who don't know, below is a variety of weld nuts, similar to what I'm using..

http://images.google.com/imgres?imgu...%3Den%26sa%3DN

What you see below are threaded metal inserts, aka 'weld nuts'. I did it this way so I wouldn't have to through-bolt and deal with trying to work with a nut on the inside of the frame (there are also some points where dealing with a nut on the inside would have been a real PITA). I feel this method will hold up pretty damn well, and if not, I'll just have to revisit it!

For those who don't know, below is a variety of weld nuts, similar to what I'm using..

http://images.google.com/imgres?imgu...%3Den%26sa%3DN

Last edited by 2002FX4; 04-14-2008 at 03:30 AM.

#25

By the way, I see you're in East Windsor, CT. That's the area where the auto dealer is that I bought my blue 2wd Ranger from last summer when I was in the region for work.

Nice!

Nice!