TIG skills (Pic Intensive)

#1

TIG skills (Pic Intensive)

Just thought I'd share my recent skills with welding...

I've already cert'd for 7018 3G 1in plate and Flux core 3G 1in plate...

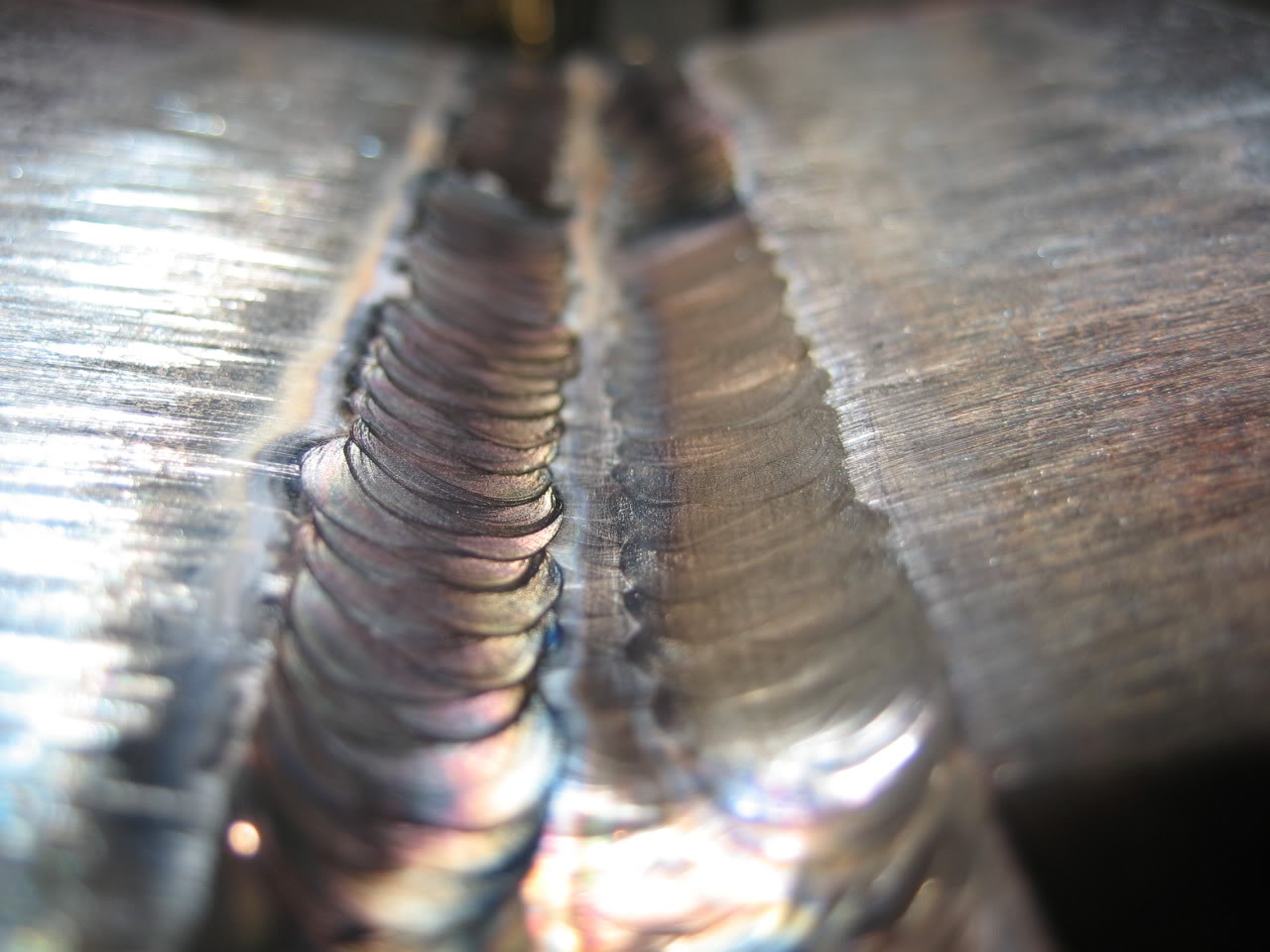

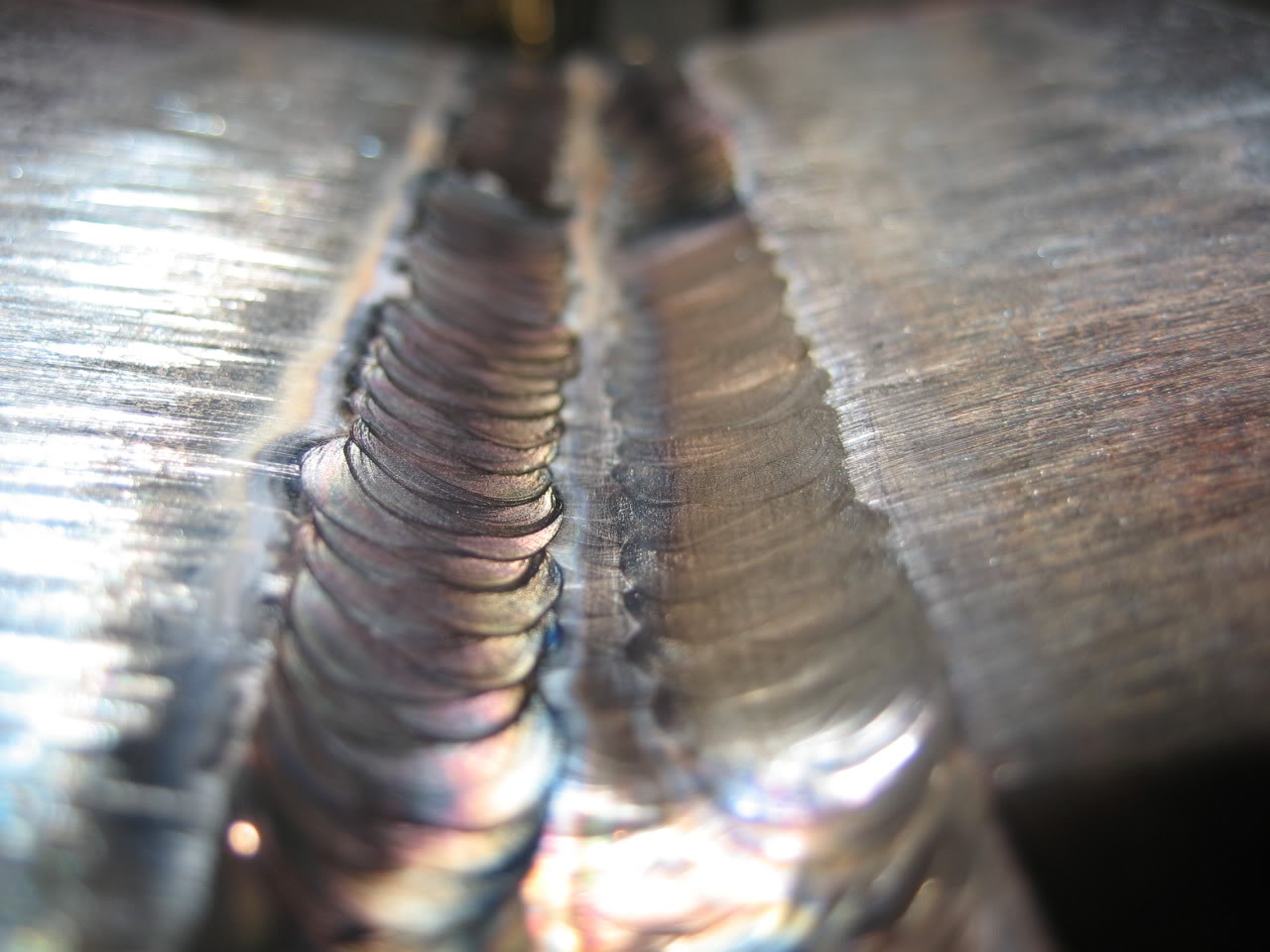

Now I'm going for my TIG 3G on Carbon steel on 1in plate (Although not too practical, will give me an unlimited thickness TIG cert in carbon steels)

Here's the pics!

I would say it took me approx 6-7 hours to complete this 1 test plate.. And it desparately needs a strong back, the high heat input of TIG sucked the plates towards each other...

But all in all, not bad. I cut out the 2 coupons where it would have been tested had it been the real deal and had one minor lack of fusion mark measuring under 1/16in meaning I would have passed no problem... Put them in the bender and did the 180 test. Gotta love in house test machines!

What do you think guys?

I've already cert'd for 7018 3G 1in plate and Flux core 3G 1in plate...

Now I'm going for my TIG 3G on Carbon steel on 1in plate (Although not too practical, will give me an unlimited thickness TIG cert in carbon steels)

Here's the pics!

I would say it took me approx 6-7 hours to complete this 1 test plate.. And it desparately needs a strong back, the high heat input of TIG sucked the plates towards each other...

But all in all, not bad. I cut out the 2 coupons where it would have been tested had it been the real deal and had one minor lack of fusion mark measuring under 1/16in meaning I would have passed no problem... Put them in the bender and did the 180 test. Gotta love in house test machines!

What do you think guys?

#2

#3

Once you learn how the puddle moves and how to move it, it's all really easy... You can see how do to it in the vertical position... Rod comes in from the top of the weld and you rock the cup side to side to spread the bead out like I have...

I love TIG, it just takes a long time.... High quality, high strength welds.... Only bad thing like I said is time it takes to make the weld, and prep time... The cleaner the surface you're welding, the better the weld will turn out.

I love TIG, it just takes a long time.... High quality, high strength welds.... Only bad thing like I said is time it takes to make the weld, and prep time... The cleaner the surface you're welding, the better the weld will turn out.

#5

#7

coming from a person who TIGs everyday of the week bout 2-4 hours a day..not shabby..welding something that thick is crazy been there done that plus vertical so i know what your dealing with..the cap looks good..your passes look undercut but doesnt matter because your filling them up..what matters is that cap..and your root pass..the biggest thing that I stress on with other people that I weld with is consistency, same size beads, straight lines and making the 1st bead look like the 1000th bead on the run..practice makes perfect! Keep it up..ill try to snap some of the pics of things i TIG at work..nothing that thick tho :) now go to bed Im already getting up for work..

#9

Thanks Evan! Figure I might as well make my mark at the school.... lol

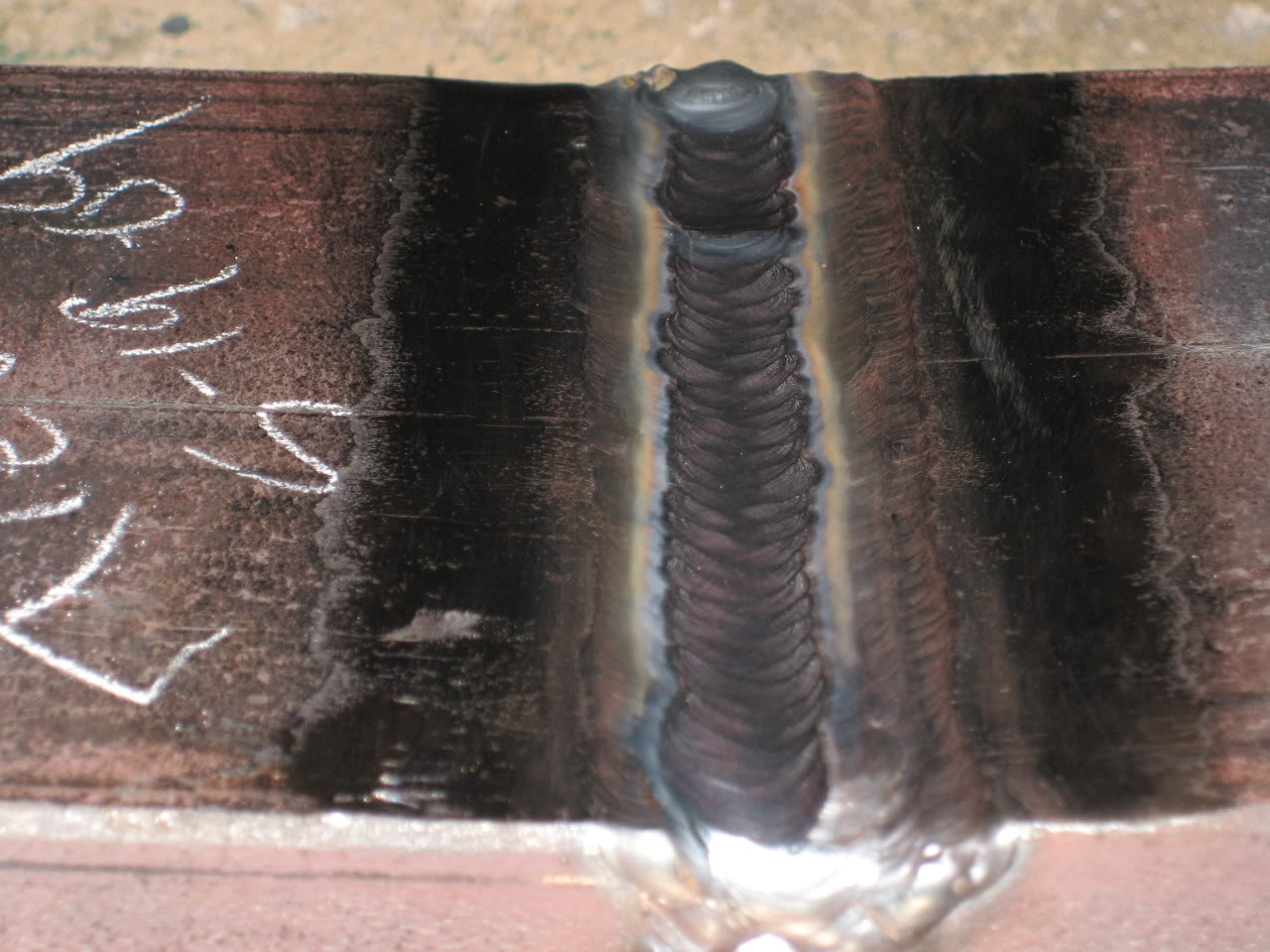

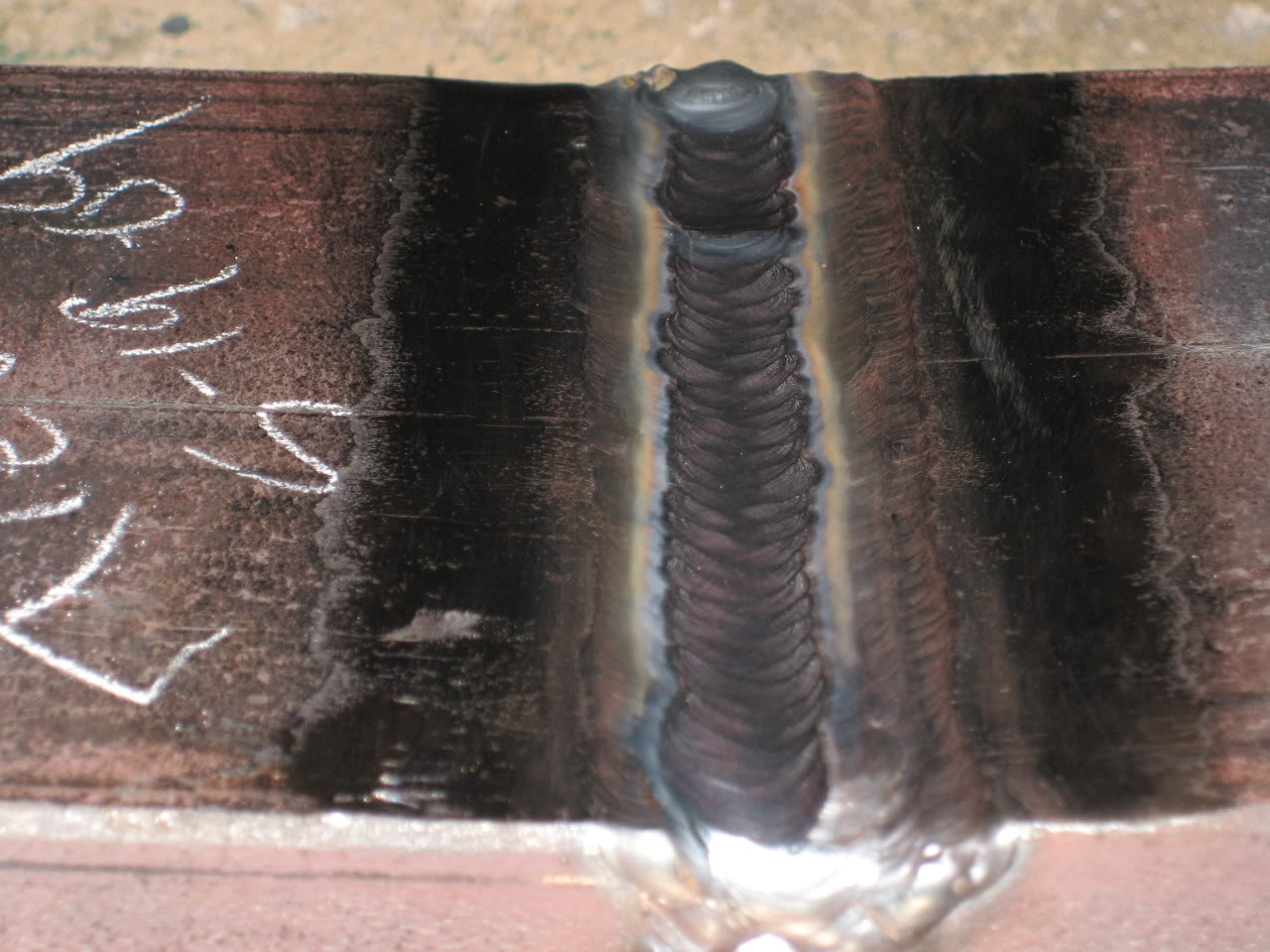

Only thing that sucks when you get to the cover pass, it's hard to see where you're going, you don't have the reflection of the arc to show you the are where you're working.... So that's what made me wander off a straight line.... But I cut the coupons of the test area and bent them up on the bender, the 180 test and they looked money... Would have totally passed.

I'm just glad I'm finally getting good with TIG. Might help me land a job where someone doesn't have TIG skills and that company is looking for a good TIG welder...

Only thing that sucks when you get to the cover pass, it's hard to see where you're going, you don't have the reflection of the arc to show you the are where you're working.... So that's what made me wander off a straight line.... But I cut the coupons of the test area and bent them up on the bender, the 180 test and they looked money... Would have totally passed.

I'm just glad I'm finally getting good with TIG. Might help me land a job where someone doesn't have TIG skills and that company is looking for a good TIG welder...

#17

Join Date: Aug 2008

Location: AZ

Posts: 789

Likes: 0

Received 0 Likes

on

0 Posts

#18

Don't tease me right now lol

Thanks man! Yeah I think it's closer to 7 hours... Each bead takes roughly 2-3 minutes, then letting it cool, cept I dunked it about every 2 passes... Which when i'm doing my cert, I won't be albe to do. Can't cool it at all, have to use a temp stick and when the metal drops below 450* you can run another pass. It takes forever lol

#19

I'd say making a 3G weld with backing on a 1" plate makes you a goof. :)

There is a reason your instructor hasn't seen it before. You only need to do 1/2" to qualify for unlimited thickness. I should go check my code book because I think you may be able to do 3/8" minimum.

I tried the 3G without backing and the root pass was so frustrating that I just gave up and went with the 3F. I didn't need the 3G for work anyway. Just wanted to see if I could do it.

There is a reason your instructor hasn't seen it before. You only need to do 1/2" to qualify for unlimited thickness. I should go check my code book because I think you may be able to do 3/8" minimum.

I tried the 3G without backing and the root pass was so frustrating that I just gave up and went with the 3F. I didn't need the 3G for work anyway. Just wanted to see if I could do it.

#20

Umm... Pretty sure in the 26 years he's been teaching and welding he knows the code. 1" in OR qualifies you for unlimited thickness. Don't know if it's different from State to state but here that's the standard.

3/8" covers you up to 3/4" thickness so it's a LIMITED THICKNESS Certification.

1" covers you on unlimited thickness. I since have Certified in Flux core 3G with backing strip as well as all 60 and 70 series rods in the 3G position with backing strip. Now I have the same certification in 3G TIG Carbon steel with backing strip.

Here's the Certification piece:

(It's an optical illusion, there is no underfill on the plate, it's about 3/32" face reinforcement)

Yes I know 1" Groove TIG isn't practical, but it shows employers I can do it and put in the time to get the job done. I did it mainly for a resume.

Next week is my TIG Certification on 3/8" 3G Stainless Steel with backing strip. That will probably top me off for certs.

After this term I'll hopefully have the following:

(1,2,3)FG TIG Carbon steel Unlimited thickness

(1,2,3)FG TIG Stainless Steel Limited Thickness (Up to 3/4")

(1,2,3)FG Flux Core (Dual Shield) Unlimited Thickness

(1,2,3)FG All 60 and 70 series Electrodes Unlimited Thickness

Reason he hasn't seen anyone do it in 26 years is 2 reasons. One being it takes 8+ hours to complete (Approx 44 passes total in the groove). The other being you would never weld something using TIG the whole process on something that thick. You'd TIG the root pass and probably flux core the rest or use E7018 for the rest.

This just put my skills and patience to the test. Broke new ground at school today and got many congrats and compliments.... I'm known as one of the best TIG welders in the department. Kinda a big pat on the back!

3/8" covers you up to 3/4" thickness so it's a LIMITED THICKNESS Certification.

1" covers you on unlimited thickness. I since have Certified in Flux core 3G with backing strip as well as all 60 and 70 series rods in the 3G position with backing strip. Now I have the same certification in 3G TIG Carbon steel with backing strip.

Here's the Certification piece:

(It's an optical illusion, there is no underfill on the plate, it's about 3/32" face reinforcement)

Yes I know 1" Groove TIG isn't practical, but it shows employers I can do it and put in the time to get the job done. I did it mainly for a resume.

Next week is my TIG Certification on 3/8" 3G Stainless Steel with backing strip. That will probably top me off for certs.

After this term I'll hopefully have the following:

(1,2,3)FG TIG Carbon steel Unlimited thickness

(1,2,3)FG TIG Stainless Steel Limited Thickness (Up to 3/4")

(1,2,3)FG Flux Core (Dual Shield) Unlimited Thickness

(1,2,3)FG All 60 and 70 series Electrodes Unlimited Thickness

Reason he hasn't seen anyone do it in 26 years is 2 reasons. One being it takes 8+ hours to complete (Approx 44 passes total in the groove). The other being you would never weld something using TIG the whole process on something that thick. You'd TIG the root pass and probably flux core the rest or use E7018 for the rest.

This just put my skills and patience to the test. Broke new ground at school today and got many congrats and compliments.... I'm known as one of the best TIG welders in the department. Kinda a big pat on the back!