How can I remove this bolt?

#1

Join Date: May 2005

Location: Jackson, New Jersey

Posts: 4,872

Likes: 0

Received 0 Likes

on

0 Posts

How can I remove this bolt?

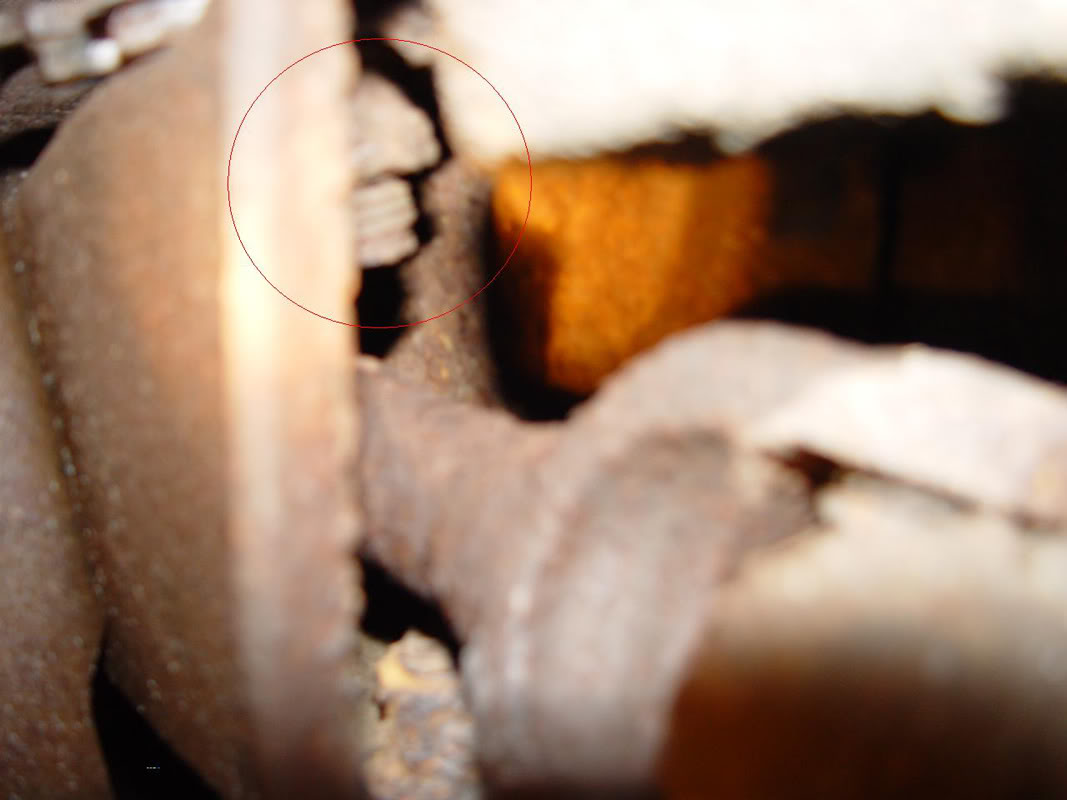

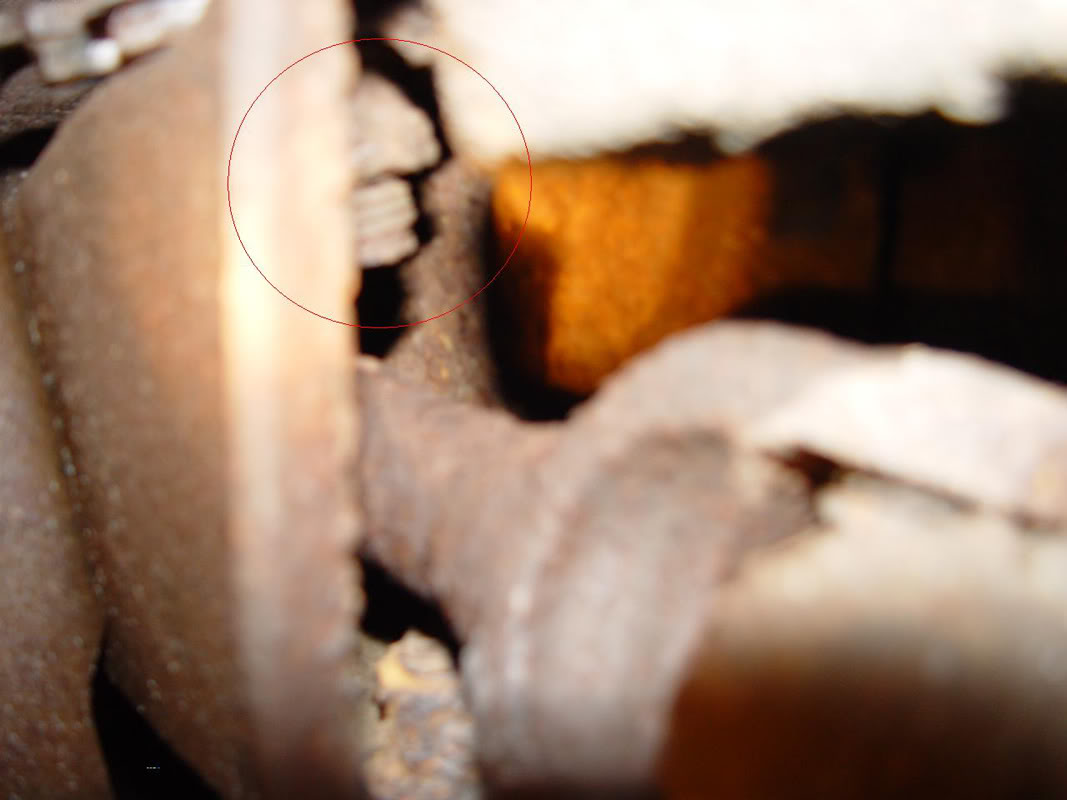

In order to get further along with my lift I have to get this part off on each beam to get to my trailing arms. This post threads into a nut welded onto the beam (cannot get to) and the springs and sway bars thread onto the top portion. The welded nut inside the beamhas a crapload of dirt and rust on it, and I can't get to it. I have soaked the part in PB Blaster (penetrant) and heated up the nut and surrounding area with a torch, but nothing has worked yet. I do not know of a socket big enough that can fit this piece, it would have to be a 1-1/8" socket that's 3-4" deep. The wrench that I tried using (with a 3' piece of conduit on the end) only strips the bolt, and the largest pipe wrench I have doesn't allow me enough torque to move the bolt, nor has the ability to fit the conduit.

Does anyone know where I can pick up a deep socket deep enough for this application?

Stuck post

My deep socket next to stuck post

*Note: socket only clears up to the chamfer, roughly 2"

Welded on nut that I cannot get to

Alternatives:

1: Cut the bolt to a point where I can get my socket on there and torque it off with the conduit. Then go to Ford and hope I can get a replacement bolt.

Pros: part comes off, everything goes back into place.

Cons: may not be too easy to find the part and I'll have to search around.

2: Cut the bolt to a point where I can get my socket on there and torque it off with the conduit. Leave the sway bar off because it won't fit on the cut up stud and put the rest of it back together.

Pros: part comes off, more articulation without the sway bar

Cons: no sway bar makes driving a full-size truck at road speeds a bit more difficult.

3: Use somebody else's idea and go from there. Hopefully somebody will have a better idea or a place to get the deep socket that I need.

Does anyone know where I can pick up a deep socket deep enough for this application?

Stuck post

My deep socket next to stuck post

*Note: socket only clears up to the chamfer, roughly 2"

Welded on nut that I cannot get to

Alternatives:

1: Cut the bolt to a point where I can get my socket on there and torque it off with the conduit. Then go to Ford and hope I can get a replacement bolt.

Pros: part comes off, everything goes back into place.

Cons: may not be too easy to find the part and I'll have to search around.

2: Cut the bolt to a point where I can get my socket on there and torque it off with the conduit. Leave the sway bar off because it won't fit on the cut up stud and put the rest of it back together.

Pros: part comes off, more articulation without the sway bar

Cons: no sway bar makes driving a full-size truck at road speeds a bit more difficult.

3: Use somebody else's idea and go from there. Hopefully somebody will have a better idea or a place to get the deep socket that I need.

#5

How bad does the TTB act without a sway bar?

I don't have much experience with that setup but as long as it's not unmanageable I would just cut it and ditch the sway bar. Especially on a trail rig.

I've had mine completely off for about the last month and don't mind driving without it. But at the same time they are two completely different trucks and may react differently without it

I don't have much experience with that setup but as long as it's not unmanageable I would just cut it and ditch the sway bar. Especially on a trail rig.

I've had mine completely off for about the last month and don't mind driving without it. But at the same time they are two completely different trucks and may react differently without it

#6

I didnt read the whole post....i guess thats one of your options....thats what i would do...if it HAS to be that long, i suggest putting a wrench on it...and then putting a wrench on the end of that to make it longer and get more torque on it....if that fails, i would just cut it down alittle bit...

Rocky

Rocky

#7

Join Date: May 2005

Location: Jackson, New Jersey

Posts: 4,872

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by RockysFord

maybe cut the end of the bolt off.......enough so your socket could reach??

Rocky

Rocky

I was told to pick up a box end wrench and cut off the other end so that I can fit the pipe on it, so far that is the best alternative.

#8

Originally Posted by RockysFord

I didnt read the whole post....i guess thats one of your options....thats what i would do...if it HAS to be that long, i suggest putting a wrench on it...and then putting a wrench on the end of that to make it longer and get more torque on it....if that fails, i would just cut it down alittle bit...

Rocky

Rocky

That failed... luckily the wrench didnt fail else that would have hurt. But yeah, we tried that and just flexed the wrench A LOT.

#10

Join Date: May 2005

Location: Jackson, New Jersey

Posts: 4,872

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Cape Fear

How bad does the TTB act without a sway bar?

I don't have much experience with that setup but as long as it's not unmanageable I would just cut it and ditch the sway bar. Especially on a trail rig.

I've had mine completely off for about the last month and don't mind driving without it. But at the same time they are two completely different trucks and may react differently without it

I don't have much experience with that setup but as long as it's not unmanageable I would just cut it and ditch the sway bar. Especially on a trail rig.

I've had mine completely off for about the last month and don't mind driving without it. But at the same time they are two completely different trucks and may react differently without it

#12

If you dont have a crafsman i wouldnt try it...but i would take a wrench....put the boxed end on there...put a pipe on the end (my floor jack pipe fits over any wrench i have, except huge ones....and then pull on that ****....it might look like its going to break but who cares, just be prepaired....

Looks like you have been spraying it in PB blaster or something to knock the rust loose??

Also heat it up....get a torch and heat it till its glowing and then use the wrench, it will come off like butta....

When we have bolts we cant get off at work (i work on semi's) we heat them up and they come right off...

Rocky

Looks like you have been spraying it in PB blaster or something to knock the rust loose??

Also heat it up....get a torch and heat it till its glowing and then use the wrench, it will come off like butta....

When we have bolts we cant get off at work (i work on semi's) we heat them up and they come right off...

Rocky

#13

Winks when i work on the rangers with the same suspension i heat with a propain torch a little then get a CLOSED end wrench and put a pipe on the and if needed. also i get someone else to pull with me usually that bolt is a *****...serously...

that holts the radii's arm on and the lower sway bar bracket you cant just ditch it and from what i see he has the sway bar off or unhooked as it is..

Originally Posted by Cape Fear

How bad does the TTB act without a sway bar?

I don't have much experience with that setup but as long as it's not unmanageable I would just cut it and ditch the sway bar. Especially on a trail rig.

I've had mine completely off for about the last month and don't mind driving without it. But at the same time they are two completely different trucks and may react differently without it

I don't have much experience with that setup but as long as it's not unmanageable I would just cut it and ditch the sway bar. Especially on a trail rig.

I've had mine completely off for about the last month and don't mind driving without it. But at the same time they are two completely different trucks and may react differently without it

#14

Join Date: May 2005

Location: Jackson, New Jersey

Posts: 4,872

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by Redneckstone

Winks when i work on the rangers with the same suspension i heat with a propain torch a little then get a CLOSED end wrench and put a pipe on the and if needed. also i get someone else to pull with me usually that bolt is a *****...serously...

Originally Posted by Redneckstone

that holts the radii's arm on and the lower sway bar bracket you cant just ditch it and from what i see he has the sway bar off or unhooked as it is..

#15

I have a few suggestions:

1) GO GET A HAYNES/CHILTONS manual!!!!

2) Go and get replacement bolts and nuts BEFORE you destroy the one you have...at least then you know you can get some...because you'll have some.

3) use a closed end wrench and a big pipe after heating the nut up

4) Does your suspension lift have instructions that address this issue? I know, I know, keep a bucket of water around to splash on your eyes as they will burn when reading instructions.

5) Cut off the top part of the bolt as if it's sticking up that much then it probably isn't needed.

If none of those work...use a hacksaw or dremmel tool or something to cut that thing off there!

other than those ideas....I dunno :)

1) GO GET A HAYNES/CHILTONS manual!!!!

2) Go and get replacement bolts and nuts BEFORE you destroy the one you have...at least then you know you can get some...because you'll have some.

3) use a closed end wrench and a big pipe after heating the nut up

4) Does your suspension lift have instructions that address this issue? I know, I know, keep a bucket of water around to splash on your eyes as they will burn when reading instructions.

5) Cut off the top part of the bolt as if it's sticking up that much then it probably isn't needed.

If none of those work...use a hacksaw or dremmel tool or something to cut that thing off there!

other than those ideas....I dunno :)

#16

Join Date: Oct 2004

Location: Coal Region, MTC to be exact...heart of the coal region.

Posts: 2,232

Likes: 0

Received 3 Likes

on

3 Posts

what the **** is that? i dont recall ever seeing that **** on any Pre i wrenched on. at least not like that.

IMO, cut if off. i dont run any sway bars from the factory and it handles fine. albeit ur a short wheel base and a little higher...just take the corners a little easier.

i cant really make out in the pics on what to do. when my dad gets home ill check out his and see.

IMO, cut if off. i dont run any sway bars from the factory and it handles fine. albeit ur a short wheel base and a little higher...just take the corners a little easier.

i cant really make out in the pics on what to do. when my dad gets home ill check out his and see.

#17

Originally Posted by Hefavitzen

I have a few suggestions:

1) GO GET A HAYNES/CHILTONS manual!!!!

1) GO GET A HAYNES/CHILTONS manual!!!!

5) Cut off the top part of the bolt as if it's sticking up that much then it probably isn't needed.

#19

Join Date: May 2005

Location: Jackson, New Jersey

Posts: 4,872

Likes: 0

Received 0 Likes

on

0 Posts

#20

Join Date: May 2005

Location: Jackson, New Jersey

Posts: 4,872

Likes: 0

Received 0 Likes

on

0 Posts

I never ordered anything to relocate my sway bars, so I am going to do away with them for the time being. Also, I don't have anything near me where I can pick up some steel tubing to make my own, nor do I have the tools to do so.

Edit: Just checked out fullsizebronco.com and they say that the sway bar doesn't do much for the handling of the Bronco so its staying off. I am still going to try the box end wrench though.

Edit: Just checked out fullsizebronco.com and they say that the sway bar doesn't do much for the handling of the Bronco so its staying off. I am still going to try the box end wrench though.

Last edited by winks; 08-09-2006 at 12:03 PM.

#21

Join Date: May 2005

Location: Jackson, New Jersey

Posts: 4,872

Likes: 0

Received 0 Likes

on

0 Posts

#23

ok, first off dont cut it because that is a special stud that is like impossible to find, and when you do its friggin expensive. use a box end wrench on it with a piece of pipe on that (Ive found that some 2 inch exhaustpipe kind of flattened out at one end will actually slip over the 1 1/8th wrench quite nicely. then grap a torch (propane, MAPP, oxy/acetalene, whatever) and heat that sucker up till it is GLOWING... there are no rubber parts near it so just heat it up truely till it is GLOWING. then throw the wrench on it and pull, if it doenst come off, PULL HARDER. getting to the lower nut will do you no good, hat is supposed to stay there, the upper nut is actually part of that piece, cranking on that upper nut will spin the stud out of the beam, the nut itself is part of the stud and doesnt spin off the stud. oh and use a good quality box wrench, as some of the cheap ones will just flex and snap. my craftsman hasnt has any issues with those, but damn is a 1 1/8th wrench big.

#25