Project Dragula: B3000 Rat rod

#127

Join Date: Nov 2005

Location: indy

Posts: 1,581

Likes: 0

Received 0 Likes

on

0 Posts

#128

spend the money and get new springs, when you cut springs you effectively change the spring rate. springs are relatively cheap. Plus you have effectively done a SAS with a 2wd axle so TTB springs are going to be super stiff.

I just saw this post. I have some major safety concerns. First, That front beam apears to be cast, what precautions are you taking for welding to it? Second welding the radius arms the the Beam is a HUGE No-no. There is a reason the radius arms are soft mounted. If you weld them they are going to break. The suspension is going to bind up and the weakest part is going to let go. Third, welding on spring steel (coil springs) changes its material properties and is also a very large No-no. Take the time and correct these problems, for your safety and those who share the road with you.

Got the front end mocked up. Mind that I haven't cut the springs yet, it's going to be much lower! If you look at the radius arms, the lower knuckle is at the level the axle will sit. To make it easy and strong, I'm just going to weld them right to the axle, if I need to take them off... Eh, rat rod. I can always unbolt from the frame and grind off. So, all I have left to do on the front end is cut the springs, weld the springs into the brackets, modify and weld on the radius arms, and fabricate brackets for, then re-attach the tie rods.

#129

I just saw this post. I have some major safety concerns. First, That front beam apears to be cast, what precautions are you taking for welding to it? Second welding the radius arms the the Beam is a HUGE No-no. There is a reason the radius arms are soft mounted. If you weld them they are going to break. The suspension is going to bind up and the weakest part is going to let go. Third, welding on spring steel (coil springs) changes its material properties and is also a very large No-no. Take the time and correct these problems, for your safety and those who share the road with you.

#130

Join Date: Nov 2005

Location: indy

Posts: 1,581

Likes: 0

Received 0 Likes

on

0 Posts

you are introducing much more force on those radius arms by fixing them to a solid beam than they originally handled while fixed to the TIB which had an additional squishy pivot bushing near the center of the truck. all the additional twisting force will be directed at your welds.

welding cast anything can be VERY tricky and generally involves preheating and controlled cool down procedures. lots of good reading can be found by googling "welding cast iron." heres a couple real quick:

http://www.lincolnelectric.com/knowl...ronpreheat.asp

http://www.mig-welding.co.uk/cast-iron.htm

i would be lookin at building some sort of combination radius arm bracket and lower coil bucket that you can attach to the original mounting holes in that beam axle, rather than trying to weld everything to it; especially not welding mild steel to a cast beam. looks like you need to make up alot of distance between the spread of the radius arm tabs and the thickness of that beam anyhow....

and add some kind of lateral locator. the radius arms dont have enough splay to locate that axle side to side.

you should be able to find springs in any circle track suspension shop, and they are cheap.

welding cast anything can be VERY tricky and generally involves preheating and controlled cool down procedures. lots of good reading can be found by googling "welding cast iron." heres a couple real quick:

http://www.lincolnelectric.com/knowl...ronpreheat.asp

http://www.mig-welding.co.uk/cast-iron.htm

i would be lookin at building some sort of combination radius arm bracket and lower coil bucket that you can attach to the original mounting holes in that beam axle, rather than trying to weld everything to it; especially not welding mild steel to a cast beam. looks like you need to make up alot of distance between the spread of the radius arm tabs and the thickness of that beam anyhow....

and add some kind of lateral locator. the radius arms dont have enough splay to locate that axle side to side.

you should be able to find springs in any circle track suspension shop, and they are cheap.

#131

I didn't think about it till you guys mentioned it but yeah I agree, a Panhard bar is definitly in the works. Any tips on making sure it's the right length, ect?

#132

Right, the radius arm is still soft mounted on the frame side. Is that not enough, or is the arm itself not strong enough?

I didn't think about it till you guys mentioned it but yeah I agree, a Panhard bar is definitly in the works. Any tips on making sure it's the right length, ect?

I didn't think about it till you guys mentioned it but yeah I agree, a Panhard bar is definitly in the works. Any tips on making sure it's the right length, ect?

#133

IIRC The Arm is hard mounted on the TTB because of the bushing on the end of the TTB beam. If you look at a 1978-1979 F150 they have bushings on both sides. This is because the bushings actually allow movement because a radius arm style suspension is essentially always binding.

#134

#135

#137

Yes... I'm liking this idea. For the same cost as a new set of springs I could get a set of leaf springs from a J/Y and then it's just 4 u bolts and 4 mounting bolts to a stupid easy to make adaptor plate. I like this plan.

Red, seriously thanks for stopping me from doing something stupid, I got ahead of myself in my excitment :-p

Red, seriously thanks for stopping me from doing something stupid, I got ahead of myself in my excitment :-p

#139

#140

So your making a rat rod.... Why are we even talking about springs? You don't have springs on a rat rod!?!?! Mount that bish straight to the frame, and run some soft sidewall tires. Seriously, and you'll get low enough then for it to make sense. To make it look really good you gotta get that thing on the ground. Stupid low. Like low enough you can't park it in the driveway low.

#141

So your making a rat rod.... Why are we even talking about springs? You don't have springs on a rat rod!?!?! Mount that bish straight to the frame, and run some soft sidewall tires. Seriously, and you'll get low enough then for it to make sense. To make it look really good you gotta get that thing on the ground. Stupid low. Like low enough you can't park it in the driveway low.

#142

I see the physics have finally come into play. There is a lot more involved then just cutting up a vehicle and peicing it back together.

Definatly do some research and keep safety in mind......especially if this thing is going to venture out on public roads.

So far it's been an interesting build-up thread. Keep it coming.

Definatly do some research and keep safety in mind......especially if this thing is going to venture out on public roads.

So far it's been an interesting build-up thread. Keep it coming.

#143

Quick update. Progress has stopped for a week or two while I wait for paychecks to come in, and I may not be able to afford parts after that untill April, spring break is coming up and that means bad things for bus drivers... That's a week without pay... Oye.

Anyway, here's a list, in loose order, of parts and prices I've budgeted on that I'm waiting on.

Leaf springs, shackles and mounts $120 (front suspention done)

Engine crossmember $100

Mount engine / parts to get engine running - $300

Trans / driveshaft - $500

Bodywork on cab - $100

Misc - (wiring ect) - $100

Total $1220

Anyway, here's a list, in loose order, of parts and prices I've budgeted on that I'm waiting on.

Leaf springs, shackles and mounts $120 (front suspention done)

Engine crossmember $100

Mount engine / parts to get engine running - $300

Trans / driveshaft - $500

Bodywork on cab - $100

Misc - (wiring ect) - $100

Total $1220

#146

I firmly believe 6 inches to frame is too much. Much much to much. lol. The lowest car I ever had was less than 1/2 and inch to the skid plate that was welded to the oil pan. I got thumbs up from everyone driving around. It was the pimpest 510 ever. Too bad this was pre-camera for me.

I think a body drop is in order, and notching the frame in the front similar to how you notch one in the rear. Or hell, put the axle OVER the frame to really get it down there.

Just saying.. lol. Go broke or go home eh?

I think a body drop is in order, and notching the frame in the front similar to how you notch one in the rear. Or hell, put the axle OVER the frame to really get it down there.

Just saying.. lol. Go broke or go home eh?

#147

I firmly believe 6 inches to frame is too much. Much much to much. lol. The lowest car I ever had was less than 1/2 and inch to the skid plate that was welded to the oil pan. I got thumbs up from everyone driving around. It was the pimpest 510 ever. Too bad this was pre-camera for me.

I think a body drop is in order, and notching the frame in the front similar to how you notch one in the rear. Or hell, put the axle OVER the frame to really get it down there.

Just saying.. lol. Go broke or go home eh?

I think a body drop is in order, and notching the frame in the front similar to how you notch one in the rear. Or hell, put the axle OVER the frame to really get it down there.

Just saying.. lol. Go broke or go home eh?

Anyway, stay tuned for a huge update! I'm not giving out any hints but I'm SO happy right now! As soon as I can take pics I'll fill ya'll in.

#148

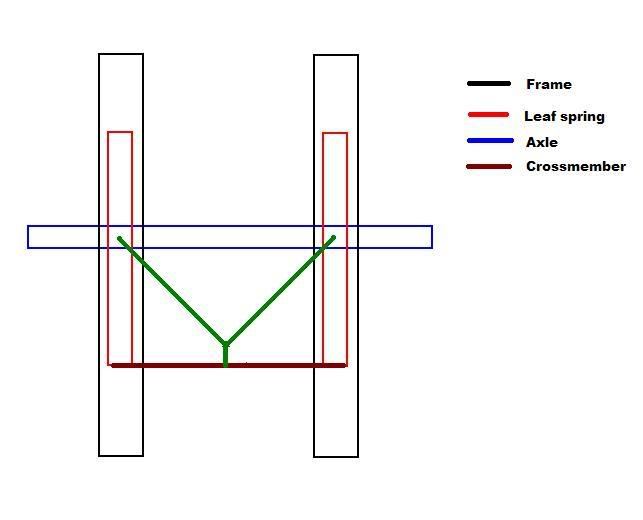

Ok, I need some input.

I'm going to go with a leaf spring suspension on the front for sure... If I get two heavy duty leaf springs, aka, 2000lbs each (the whole things weighs maybe 3000lbs) and use u bolts on the axle side through pre existing mounts, and going to shackles to brackets welded to the frame, would I need to use radius arms or a panhard bar? Or would the leaf springs locate the axle well enough without?

I'm going to go with a leaf spring suspension on the front for sure... If I get two heavy duty leaf springs, aka, 2000lbs each (the whole things weighs maybe 3000lbs) and use u bolts on the axle side through pre existing mounts, and going to shackles to brackets welded to the frame, would I need to use radius arms or a panhard bar? Or would the leaf springs locate the axle well enough without?

#149

Ok, here we go. God, buddha, or whoever is up there is definitly smiling upon my little project.. This is by far my MOST PROFITABLE CRAIGSLIST FIND EVER. HAHAHA SWEET!!! I randomly checked the free section of Craigs, and saw a post for scrap metal in my town, all the ad said was "200-300lbs of scrap, mostly steel. Come to _____ and come to backyard, I'll be there all night." I figured that was a good $5 or so in scrap, and the guy lives literally a quarter mile from me, so I figured what do I have to lose? So I head on over, and I was the first to get there... Sure enough there was a huge pile of scrap, but it was a huge pile of old auto parts! Heaven on Earth!

See it?

How about now?

THERE IT IS!!! Yes sir, sitting right on top of the pile was a 4 speed toploader transmission. I asked the guy about it and he said he didn't think there's anything really wrong with it, except he didn't have the bell or tail housing and didn't want to spend the time or effort to try and sell it. Hell yeah! I'll probably rebuild it for good measure, but still, SCORE! I was looking at transmissions earlier and decided to go with and old toploader 4 speed, and was gearing up to spend $300 or more, and fate drops this little gem in my lap. BUT WAIT! THERE'S MORE!

Leaf spings! 4 of em! (only 2 shown in pictures). They look PERFECT, too. I need to wait till the sun comes up, but they look like they are about 20" long, 6" tall, and in the 1000-1500lb range, with twin eyes, AKA, EXACTLY what I was about to spend $130 on. I need to see if I can find a part number on them and find out the weight limit too.

Other random crap I got, transfer case for a 60's or 70's Landcruiser in great shape, a carb that I'm hoping will fit on the army jeep, and a huge bucket of every kind of bolt, pulley, and bracket a man could hope for.

Tomorrow will be fun as hell... I'm so in the mood to stay up late, but this mornign I got in a drunken jalepeno eating competition and I'm stuck inside... Oy vey.

See it?

How about now?

THERE IT IS!!! Yes sir, sitting right on top of the pile was a 4 speed toploader transmission. I asked the guy about it and he said he didn't think there's anything really wrong with it, except he didn't have the bell or tail housing and didn't want to spend the time or effort to try and sell it. Hell yeah! I'll probably rebuild it for good measure, but still, SCORE! I was looking at transmissions earlier and decided to go with and old toploader 4 speed, and was gearing up to spend $300 or more, and fate drops this little gem in my lap. BUT WAIT! THERE'S MORE!

Leaf spings! 4 of em! (only 2 shown in pictures). They look PERFECT, too. I need to wait till the sun comes up, but they look like they are about 20" long, 6" tall, and in the 1000-1500lb range, with twin eyes, AKA, EXACTLY what I was about to spend $130 on. I need to see if I can find a part number on them and find out the weight limit too.

Other random crap I got, transfer case for a 60's or 70's Landcruiser in great shape, a carb that I'm hoping will fit on the army jeep, and a huge bucket of every kind of bolt, pulley, and bracket a man could hope for.

Tomorrow will be fun as hell... I'm so in the mood to stay up late, but this mornign I got in a drunken jalepeno eating competition and I'm stuck inside... Oy vey.

#150