Traction bars

#1

Traction bars

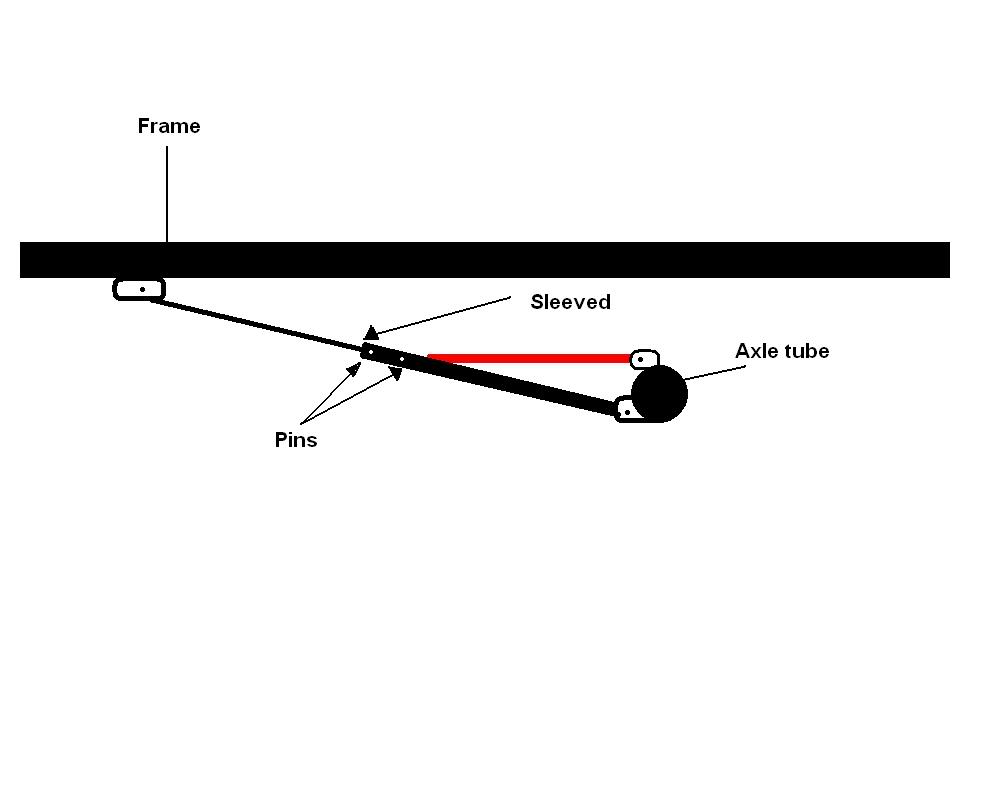

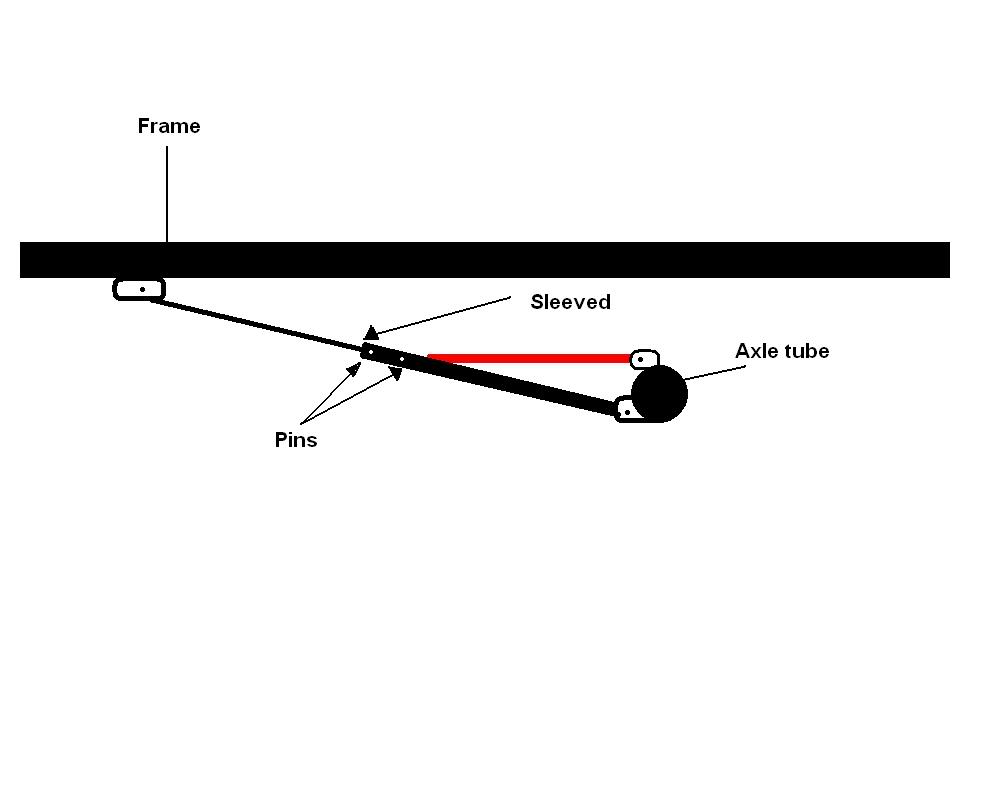

How bad do you guys think a set of traction bars would hurt my flex in the rear? I ask because i have some pretty good axle hop in the rear end with the new chevy springs. I was thinking somthing like this for the rear without the u-joint deal i would just use a heim up there.

I was also thinking something like this the black tube would be sleeved and have pins for on the road and at the dunes and such where as much flex is not needed and when i go trail riding i could pull the pins and then would have all my flex back. Would the red bar be needed in my situation where i have axle hop kand not so much wrap.

I was also thinking something like this the black tube would be sleeved and have pins for on the road and at the dunes and such where as much flex is not needed and when i go trail riding i could pull the pins and then would have all my flex back. Would the red bar be needed in my situation where i have axle hop kand not so much wrap.

Last edited by ford rules; 03-30-2009 at 08:13 PM.

#4

#5

#7

#8

#9

#10

#14

#15

Thats the design I'm going to copy, except make sure where the upper and lower pieces come together is as far up as you can get it. and no, I'm pretty sure that design won't limit your travel at all, and if it does a very small amount. just make it out of some strong material.

pinion angle has a lot to do with it... but he's still gotta get something in there eventually.. there's a reason most leaf sprung trucks have them haha

no need for a shackle, he's doing the twist and slip it looks like.

no need for a shackle, he's doing the twist and slip it looks like.

#16

Thats the design I'm going to copy, except make sure where the upper and lower pieces come together is as far up as you can get it. and no, I'm pretty sure that design won't limit your travel at all, and if it does a very small amount. just make it out of some strong material.

pinion angle has a lot to do with it... but he's still gotta get something in there eventually.. there's a reason most leaf sprung trucks have them haha

no need for a shackle, he's doing the twist and slip it looks like.

pinion angle has a lot to do with it... but he's still gotta get something in there eventually.. there's a reason most leaf sprung trucks have them haha

no need for a shackle, he's doing the twist and slip it looks like.

As the suspension compresses the "traction bar" will try to push the axle back, when it droops it will try to drag it forward. How much, I have no idea. May or may not be enough to notice on the road but I wouldn't want it solid mounted like that at any time.

#17

it wouldn't be solid mounted? what pins?

the pic he has is the axle shaft (smaller diameter) inside another piece of tube or pipe.. they slide in and out as the axle droops, then is allowed to rotate with the axle..

unlesssss that's how he was imaging it.. but it has to either be able to slip inside each other, or have a shackle, something's gotta give.

the pic he has is the axle shaft (smaller diameter) inside another piece of tube or pipe.. they slide in and out as the axle droops, then is allowed to rotate with the axle..

unlesssss that's how he was imaging it.. but it has to either be able to slip inside each other, or have a shackle, something's gotta give.

Last edited by 99ranger4x4; 03-30-2009 at 11:13 PM.

#18

he needs to have the pinion angle set so its the same angle at the top. you cant have it straight at the bottom because then the angle goes over flat when he accelerates. Like Jey was mentioning.

#19

with those springs he should have little to no axle wrap with no more power than what he is putting out.

he needs to have the pinion angle set so its the same angle at the top. you cant have it straight at the bottom because then the angle goes over flat when he accelerates. Like Jey was mentioning.

he needs to have the pinion angle set so its the same angle at the top. you cant have it straight at the bottom because then the angle goes over flat when he accelerates. Like Jey was mentioning.

#20

#21

As you change the rear angle, the front angle is going to change too. They need to be almost equal/opposite. 1-2 degrees down at the pinion to to make up for slight axle rotation during acceleration. 1 degree difference is needed to make slight friction for the bearings to turn.

Someone correct me if I'm wrong please.

Someone correct me if I'm wrong please.

#22

with those springs he should have little to no axle wrap with no more power than what he is putting out.

he needs to have the pinion angle set so its the same angle at the top. you cant have it straight at the bottom because then the angle goes over flat when he accelerates. Like Jey was mentioning.

he needs to have the pinion angle set so its the same angle at the top. you cant have it straight at the bottom because then the angle goes over flat when he accelerates. Like Jey was mentioning.

but why can't he have a traction bar? its not like its a bad thing to have..

#24

Join Date: Jun 2008

Location: Mooresville, NC

Posts: 5,584

Likes: 0

Received 0 Likes

on

0 Posts

#25

[/QUOTE]

[/QUOTE]