IFS Dropped X Member & Bracketry

#1

IFS Dropped X Member & Bracketry

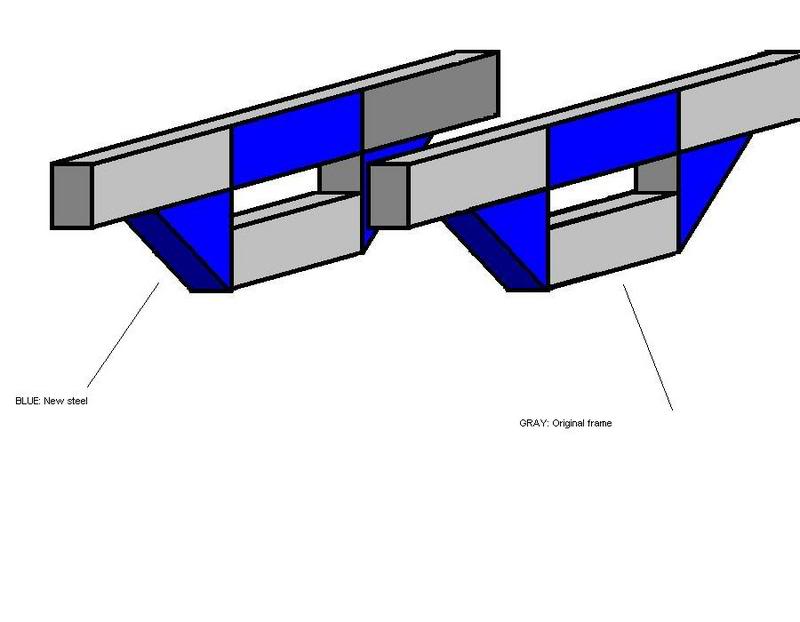

I have been toying with this idea for a while now about fabricating my own dropped bracketry and mounts to simply lower the mounting point of my suspension to give me clearance for bigger tires. I'm not worried about wheel travel because I dont offroad too much but my idea was to gain additional clearance without spending loads of money or changing angles in the suspension geometry. Any thoughts? I have access to all the tools I need, it would just be a matter of labor to build the stuff.

I am trying to plan this out as cheap as possible since I can do all my own welding and fabrication it would be material cost only. It would just be ALOT of work.

I am trying to plan this out as cheap as possible since I can do all my own welding and fabrication it would be material cost only. It would just be ALOT of work.

#3

That would be a real accomplishment. Homemade lifts used to be common but not so much anymore with all the "kits" out there. Wouldn't be a bad idea to emulate one of the better ones as the engineering is mostly done and all you have to do is reproduce it as best you can.

I think you can have a greater feeling of satisfaction about the things you build up yourself on your truck. This is true even for just installing kits -- but especially so when it's something you made yourself as well.

I think you can have a greater feeling of satisfaction about the things you build up yourself on your truck. This is true even for just installing kits -- but especially so when it's something you made yourself as well.

#4

#5

I'm not saying this would be any easy thing either. I've made a lawn tractor go 40mph and that was a real challenge to design it, but it did work. I work in a sheet metal shop so I can get a lot of scrap for free, though mostly thin gauge. My dad just bought a nice miller welder last year(the big gas driven generator kind) and welding plate is easy. If all else fails I can tack everything and get him to finish since he is a certified weldor. I kind of like the challenge factor to it. It would be nice if I could get my hands on a 98 front end to use to mock up all the stuff. Still not iron clad on this but I've been keeping it open the more I look at it.

#6

#7

I am about 90 miles northwest of Philly in Northern Berks county. I would most likely need anywhere from 1/4- 3/16 for some of the brackets and if I need to modify the crossmember, maybe half inch. I have to take some pictures and get some measurements but I have a rough idea of what I need to do. I haven't really decided how much of a drop I want, but I was thinking maybe 6" max. I still need to check out the steering and see how everything there is connected. Right now I'm waiting for the battery in the camera to charge so I can get some pics. I have autocad as well so once I do get some numbers I can draw something up to better visualize it. If I want to get really fancy I'll get my book out and try and model it in 3d but don't hold your breath for that ![Help[1]](https://www.ranger-forums.com/rf/forum2/images/smilies/help[1].gif)

![Help[1]](https://www.ranger-forums.com/rf/forum2/images/smilies/help[1].gif)

#8

Well, what we consider scrap, you might consider good stock, lol. We have a facility for cutting near-net-shape pieces as a value-added sales tool. The leftover pieces from that operation would probably furnish you with large enough pieces to cut your shapes.

Don't know if it's cost effective for you to drive down here, but let me know and I'll see what I can dig up when the time comes.

Don't know if it's cost effective for you to drive down here, but let me know and I'll see what I can dig up when the time comes.

#10

Hey, I was considering doing the same thing on mine. Is the 98 T-Bars or coils? The only problem that I forsee is the fact of lowering the upper A-arm. The lower A-arm and front diff. are easy as they are under the frame and can just be dropped with brackets. The upper arm, however, mounts directly above the frame.

The only way I see to do it is to move the upper arm all the way down to the bottom of the frame, like 6" or so. But, then you might run into problems of having the upper A-arm on the bottom of the frame and also having brackets to go all the way down to the lower A-arm under there as well, it might get crowded. Also, the lower brackets would have to be pretty long, and I don't know about the rigidity of it with everything being suspended under the frame like that, even with crossmembers and the works.

The solution that I came to that I think would be the best balance between saving money and not involving too many man-hours would be to replicate the Superlift. By just fabbing up brackets for the lower A-arms and diff., with a couple crossmembers, you would not sink too much time into the project and still get some lift. But the downside, moneywise, is that you will have to get some Superlift spindles which are 4 " longer to reach up to the stock-position upper A-arm. They might not be bad though if you can land a used set.

I am going to get in touch with Superlift tomorrow for the same reason, just seeing about some spindles. I will let you know what they say for a price.

Storrow

The only way I see to do it is to move the upper arm all the way down to the bottom of the frame, like 6" or so. But, then you might run into problems of having the upper A-arm on the bottom of the frame and also having brackets to go all the way down to the lower A-arm under there as well, it might get crowded. Also, the lower brackets would have to be pretty long, and I don't know about the rigidity of it with everything being suspended under the frame like that, even with crossmembers and the works.

The solution that I came to that I think would be the best balance between saving money and not involving too many man-hours would be to replicate the Superlift. By just fabbing up brackets for the lower A-arms and diff., with a couple crossmembers, you would not sink too much time into the project and still get some lift. But the downside, moneywise, is that you will have to get some Superlift spindles which are 4 " longer to reach up to the stock-position upper A-arm. They might not be bad though if you can land a used set.

I am going to get in touch with Superlift tomorrow for the same reason, just seeing about some spindles. I will let you know what they say for a price.

Storrow

#12

The way I figure it, if I use some thick plate and some ingenuity I can make everything rock solid. I thought the same thing about the upper A-arms and since I got the camera working I should be able to get pics tomorrow if the weather permits. Some frame boxing is not out of the question to strengthen the front if I think it's necessary. And when I say thick plate, I mean half inch, perhaps slightly bigger depending on how it has to be setup. I will need to get some pics and measurements and just sit down and look at how I want to do it.

#13

I can dig up anything up to about 1/2 inch for you probably. Beyond that the sheer weight of the plate becomes a problem to transport.

I got a stack of about six 1/4" plates and six 3/8" plates, each 2' x 2' in my truck once for TBarCYa...and I was sagging, lol. So I threw a 28 spline 8.8 back there as well and I was nearly riding on the bumpstops. I drove over anyway...gently.

3/8 might be a good choice for the lower bracketry. The other thing you can do is run long supports from the back of the bracket to the tranny crossmember or the frame. That braces the drop brackets against impacts that might otherwise distort them or their mounts.

I've seen that done in commercial kits in the magazines and Ben (Ranger1) had a lift that had that. At first I thought he still had torsion bars, lol -- but then he showed me the coilovers and that what I took for t-bars was actually braces for the drop brackets.

I got a stack of about six 1/4" plates and six 3/8" plates, each 2' x 2' in my truck once for TBarCYa...and I was sagging, lol. So I threw a 28 spline 8.8 back there as well and I was nearly riding on the bumpstops. I drove over anyway...gently.

3/8 might be a good choice for the lower bracketry. The other thing you can do is run long supports from the back of the bracket to the tranny crossmember or the frame. That braces the drop brackets against impacts that might otherwise distort them or their mounts.

I've seen that done in commercial kits in the magazines and Ben (Ranger1) had a lift that had that. At first I thought he still had torsion bars, lol -- but then he showed me the coilovers and that what I took for t-bars was actually braces for the drop brackets.

#14

Yeah, good point about the brackets, it never occurred to me. I was just seeing everything hanging down a great distance to reach the lower A-arm, with only side-to-side support from crossmembers or X-brackets. It seemed iffy to have the force from bumps trying to move the lower, and now the upper A-arm, backwards all going through the same bracketry way up to the frame. But, with some "ladder bars" going rearward, it might be a possibility. And, if you did that you could keep the distance the same between the lower and uppar arms, thereby keeping stock spindles, saving more money.

Storrow

P.S. I'm still going to get in touch with Superlift about their 4" longer spindles just in case, more on what they say later.

Storrow

P.S. I'm still going to get in touch with Superlift about their 4" longer spindles just in case, more on what they say later.

#15

I've had 3/4 ton of steel plate in the back of my ranger already and it was something else to get to the scrap yard but I made it  If all else fails I can harrass my brother to bring his 250 with the 7.3 or my parents excursion with the trailer. I don't think I will need enough to make the truck sag too bad

If all else fails I can harrass my brother to bring his 250 with the 7.3 or my parents excursion with the trailer. I don't think I will need enough to make the truck sag too bad  Oh, and I should have pictures today.

Oh, and I should have pictures today.

If all else fails I can harrass my brother to bring his 250 with the 7.3 or my parents excursion with the trailer. I don't think I will need enough to make the truck sag too bad

If all else fails I can harrass my brother to bring his 250 with the 7.3 or my parents excursion with the trailer. I don't think I will need enough to make the truck sag too bad  Oh, and I should have pictures today.

Oh, and I should have pictures today.

#16

Join Date: Nov 2005

Location: indy

Posts: 1,581

Likes: 0

Received 0 Likes

on

0 Posts

i had big plans on doin sumthin similar a while back. my ramblings about it are in an old thread on ORR.....http://www.offroadrangers.com/forum/...ht=custom+lift

at this point, i got hooked up with a cheap(er) used RCD, and that is teh direction i will be goin this spring. i am gonna modify their configuration slightly to allow it to function the way i want it to.

there are a couple things to consider that i dont see in your ideas.

tie rod angles, for one. if you are lookin at 6" you are definatley gonna hafta do sumthin about tie rod angles. rough ideas from me would include lowerin the rack or spacing up the pickup point at the spindle. i doubt you will have enough room to space them up that far.

also for your upper arm, relocation is gonna take major hackin on the frame to keep a good geometry. if you move it to the outside of the rail, it gets supper short and the geometry goes south fast. one option for that would be a ball joint spacer similar to trailmasters kit, but again 6" is alot of extension......

the frame itself is only 1/8" thick. anything heavier than 3/16"-1/4" is overkill. boxing and gussets are your friend.

good luck, and keep your eyes open on ebay. there was a set of RCD spindles on there not too long ago that woulda helped your project imensely!

at this point, i got hooked up with a cheap(er) used RCD, and that is teh direction i will be goin this spring. i am gonna modify their configuration slightly to allow it to function the way i want it to.

there are a couple things to consider that i dont see in your ideas.

tie rod angles, for one. if you are lookin at 6" you are definatley gonna hafta do sumthin about tie rod angles. rough ideas from me would include lowerin the rack or spacing up the pickup point at the spindle. i doubt you will have enough room to space them up that far.

also for your upper arm, relocation is gonna take major hackin on the frame to keep a good geometry. if you move it to the outside of the rail, it gets supper short and the geometry goes south fast. one option for that would be a ball joint spacer similar to trailmasters kit, but again 6" is alot of extension......

the frame itself is only 1/8" thick. anything heavier than 3/16"-1/4" is overkill. boxing and gussets are your friend.

good luck, and keep your eyes open on ebay. there was a set of RCD spindles on there not too long ago that woulda helped your project imensely!

#18

Originally Posted by gumby

i had big plans on doin sumthin similar a while back. my ramblings about it are in an old thread on ORR.....http://www.offroadrangers.com/forum/...ht=custom+lift

also for your upper arm, relocation is gonna take major hackin on the frame to keep a good geometry.

also for your upper arm, relocation is gonna take major hackin on the frame to keep a good geometry.

#19

I just had an idea... which to tell you the truth I am almost ashamed of. I guess my inner redneck is showing in this one but that whole extra front clip thing got me thinking. What if I just cut the frame out of my truck and dropped the whole clip, then put some rectangular steel tubing in place of the original and welded in supports. This sounds like the easiest(laziest) possible way to get more tire clearance without having to make new brackets for all the mounts while still retaining all the stock geometry. And you know that still leaves room for a lift afterwards(I'm just kidding)

#22

Join Date: Nov 2005

Location: indy

Posts: 1,581

Likes: 0

Received 0 Likes

on

0 Posts

#23

its funny ya'll are mentioning this. I was trying to think of the exact thing on the way home from school about a week back. It can be done, if you think on it, all the superlift is if im not mistaking, is drop brackets for the t-bars, and lower a-arms and then just new spindles and rear lift blocks. If you could move the upper a-arms to the position of the lower a-arms, and then as you stated, just make a new crossmember to house the lower a-arms mounts, it would be pretty well done, you however would still need to make the drop brackets for the t-bars, right? and then something for the front sway bar. As soon as I get back to school, I may head over to the milling machine in the engineering building and start fabing some stuff up. my plans were either to try to make the drop brackets, and if I messed up, have the back up plan of a straight axle.

Last edited by UNCCRang49; 12-25-2006 at 01:09 PM.

Thread

Thread Starter

Forum

Replies

Last Post

For Sale: Stock 4x4 Drivetrain & IFS Arizona

outdoorsman

OLD - Engine & Drivetrain

0

10-25-2009 01:04 AM

You can always buy my SL kit...

You can always buy my SL kit...