Ford 2.3L DuraTec Rebuild

#1

Ford 2.3L DuraTec Rebuild

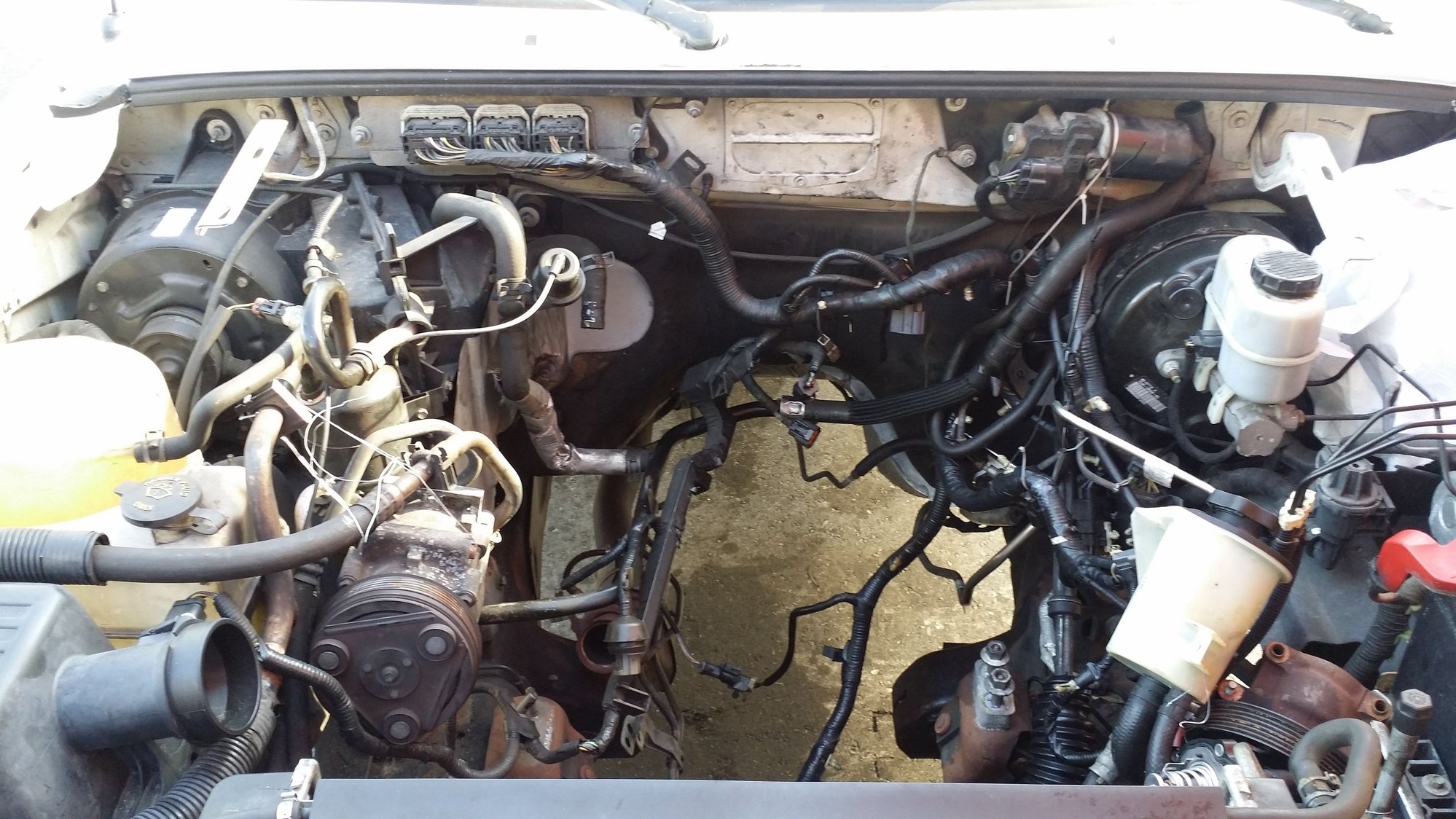

My 2007 Ford Ranger with a 2.3L DuraTec engine needs to be rebuilt. This is my work truck with a 7' bed with a topper on it that hauls around 500lbs all the time and another 550 when the water tank is full. The 2.3L DuraTec has done very well but after 130,000 miles it gave up. Check out my other thread on what happened to the engine to make me have to rebuild here.

I have the Head at the machine shop and should hear from them this week. The engine block will be out and off to the machine shop this week. I will say removing the head first makes it much easier to get to the bolts that hold the bell housing to the motor off.

Both Chilton and Haynes manuals have no specifications for this motor needed to rebuild the motor I am hoping someone can point me to this information.

I have the Head at the machine shop and should hear from them this week. The engine block will be out and off to the machine shop this week. I will say removing the head first makes it much easier to get to the bolts that hold the bell housing to the motor off.

Both Chilton and Haynes manuals have no specifications for this motor needed to rebuild the motor I am hoping someone can point me to this information.

Last edited by Mediasvi; 06-07-2020 at 07:46 PM.

The following users liked this post:

Rock304 (06-08-2020)

#2

Ok, I found this for engine specification so far. If you know of any other info on this please share.2.3 Duratec:

General Specifications Item Specification

Displacement 2.3L

No. of cylinders 4

Bore/stroke 87.5/94.0

Firing order 1-3-4-2

Oil pressure (hot @ 2,000 rpm) 29-39 psi 200-268 kPa

Belt tension Refer to Section 303-05.

Oil capacity 4.1 qts. + 0.4 qt. with filter

Cylinder Block

Cylinder bore diameter 87.5-87.53 mm (3.444-3.445 in.)

Cylinder bore maximum out-of-round 0.008 mm (0.0003 in.)

Main bearing bore diameter 57.020-57.038 mm (2.244-2.245 in.)

Head gasket surface flatness 0.1 mm/general 0.05 mm/200 x 200 (0.004 in./general) (0.0019 in./7.87 x 7.87)

Piston

Diameter (1) 87.5-87.51 mm (3.444-3.445 in.)

Diameter (2) 87.51-87.52 mm (3.4452-3.4456 in.)

Diameter (3) 87.52-87.53 mm (3.444-3.446 in.)

Piston-to-bore clearance 0.025-0.045 mm (0.0009-0.0017 in.)

Ring groove width — top 1.203-1.205 mm (0.0473-0.0474 in.)

Ring groove width — 2nd 1.17-1.19 mm (0.0.460-0.0468 in.)

Ring groove width — oil 2.501-2.503 mm (0.0984-0.0985 in.)

Piston skirt coating thickness 0.008-0.020 mm (0.0003-0.0007 in.)

Piston Pin

Diameter 20.995-21.0 mm (0.8266-0.8268 in.)

Length 59.6-60.4 mm (2.346-2.377 in.)

Piston-to-pin clearance 0.008-0.016 mm (0.0003-0.0006 in.)

Pin-to-rod clearance Press fit

Cylinder Head

Valve lift @ zero lash (exhaust) 7.4 mm

Valve lift @ zero lash (intake) 7.9 mm

Valve guide diameter 5.509-5.539 mm (0.216-0.218 in.)

Valve seat width — intake/exhaust 0.99-1.84 mm (0.038-0.072 in.)

Valve seat angle 45 degrees

Valve seat runout 0.075 mm (0.0029 in.)

Valve lash adjuster bore diameter 31.00-31.03 mm (1.220-1.221 in.)

Cam bore diameter 25.015-25.040 mm (0.984-0.985 in.)

Valve

Valve head diameter — intake 34.85-35.15 mm (1.372-1.383 in.)

Valve head diameter — exhaust 29.85-30.15 mm (1.175-1.187 in.)

Valve stem diameter — intake 5.470-5.485 mm (0.2153-0.2159 in.)

Valve stem diameter — exhaust 5.465-5.480 mm (0.2151-0.2157 in.)

Valve stem-to-guide clearance — intake 0.0027 mm (0.0001 in.)

Valve stem-to-guide clearance — exhaust 0.0029 mm (0.00011 in.)

Valve face runout 0.05 mm (0.001 in.)

Valve face angle 45 degrees

Valve Spring — Compression Pressure

Intake and exhaust (installed) 38.667 lbs.

Intake (valve open) 8.9 mm (0.35 in) of lift 97.032 lbs.

Exhaust (valve open) 7.4 mm of lift 93.338 lbs.

Free length 44.92 mm (1.768 in.)

Assembled height 37.9 mm (1.492 in.)

Crankshaft

Main bearing journal diameter 51.980-52.000 mm (2.046-2.047 in.)

Production repair 51.730-51.750 mm (2.036-2.037 in.)

Main bearing clearance 0.019-0.035 mm (0.0007-0.0013 in.)

Connecting rod journal diameter 49.980-50.000 mm (1.967-1.968 in.)

Production repair 49.730-49.750 mm (1.957-1.958 in.)

End play 0.22-0.43 mm (0.008-0.016 in.)

Rings

Width — top 1.17-1.185 mm (0.0460-0.0466 in.)

Width — 2nd 1.197-1.199 mm (0.0471-0.0472 in.)

Width — oil 2.38-2.45 mm (0.093-0.096 in.)

Ring gap (in bore) — top 0.16-0.31 mm (0.006-0.012 in.)

Ring gap (in bore) — 2nd 0.33-0.48 mm (0.012-0.018 in.)

Ring gap (in bore) — oil 0.2-0.7 mm (0.007-0.027 in.)

Valve Tappet

Diameter 30.97-30.98 mm (1.2192-1.2196 in.)

Tappet-to-valve clearance — intake 0.22- 0.28 mm (0.008-0.011 in.)

Tappet-to-valve clearance — exhaust 0.27-0.33 mm (0.010-0.013 in.)

Tappet-to-bore clearance 0.02-0.06 mm (0.0007-0.0023 in.)

Camshaft

Lobe lift — intake 8.24999 mm (0.324 in.)

Lobe lift — exhaust 7.80007 mm (0.307 in.)

Runout (1)a 0.03 mm (0.001 in.)

Thrust clearance 0.09-0.24 mm (0.003-0.009 in.)

Journal diameter 24.96-24.98 mm (0.982-0.983 in.)

Journal-to-bore clearance 0.035-0.080 mm (0.001-0.003 in.)

Connecting Rod

Bearing clearance 0.027-0.052 (0.001-0.002 in.)

Bearing thickness 1.496-1.520 mm (0.058-0.059 in.)

Crank bore diameter 53.025-53.045 mm (2.087-2.088 in.)

Pin bore diameter 20.965-20.985 mm (0.825-0.826 in.)

Length (center to center) 154.8 mm (6.094 in.)

Side clearance 1.95-3.05 mm (0.076-0.120 in.)

Axial clearance 0.14-0.36 mm (0.005-0.014 in.)

a No. 3 Journal — Supported by No. 1 and No. 5 journals.

General Specifications Item Specification

Metal Surface Cleaner F4AZ-19A536-RA WSE-M5B392-A

Silicone Gasket and Sealant F7AZ-19554-EA WSE-M4G323-A4

Super Premium SAE 5W-20 Engine Oil XO-5W20-QSP WSS-M2C153-H

MERPOL® O-Ring Seal Lubricant ESE-M99B144-B

Torque Specifications Description Nm lb-ft lb-in

Camshaft bearing capsa — — —

Coolant outlet connection bolts 10 — 89

Oil pan boltsa — — —

Oil pump-to-engine block bolts 25 18 —

Cylinder head boltsa — — —

Intake manifold bolts 18 13 —

Flywheel bolta — — —

Crankshaft pulley bolta — — —

Crankshaft position sensora — — —

Crankshaft oil seal retainera — — —

A/C compressor mounting bolts 25 18 —

Oil pump sprocket bolt 25 18 —

Knock sensor 20 15 —

Engine plug bolt 20 15 —

Rear engine mounting nut 133 98 —

Front engine mounting nuts 80 59

Motor mount bracket bolts 48 35

Engine roll-restrictor bolts 48 35

Engine-to-bellhousing bolts 48 35 —

Torque converter-to-flywheel nuts 35 26 —

Starter motor mounting bolts 25 18 —

Power steering press line tube nut 20 15 —

Powertrain control module (PCM) wiring connector 6 — 53

Coolant pump bolts 10 — 89

Engine front cover boltsa — — —

Camshaft sprocket bolt 72 53 —

Valve cover bolts 10 — 89

Engine lifting eye bolts 45 33 —

Exhaust gas recirculation (EGR) valve assembly bolts 25 18 —

Generator mounting bolts 25 18 —

Thermostat assembly bolts 10 — 89

Oil pump screen and cover assembly 10 — 89

Exhaust manifold studs 17 13 —

Exhaust manifold-to-cylinder head nuts 54 40 —

Coolant pump pulley bolts 25 18 —

Crankshaft position (CKP) sensor boltsa — — —

Generator A/C mounting bracket bolts 48 35 —

Power steering pump mounting bolts 25 18 —

Engine ground cable-to-cylinder head bolt 10 — 89

Oil level indicator tube bolt 10 — 89

Engine wire harness bulkhead connector bolt 10 — 89

Engine body ground bolt 10 — 89

Engine harness ground PCM connector nut 10 — 89

Accelerator control splash shield 8 — 71

Oil pressure sensor 15 11 —

A/C manifold tube bolt 20 15 —

Exhaust manifold-to-exhaust inlet pipe nuts 40 30 —

Transmission tubes bracket bolt 28 21 —

Oil drain plug 28 21 —

Oil pump chain tensioner bolts 10 — 89

Oil pump chain guide bolts 10 — 89

Timing chain guide bolts 10 — 89

Timing chain tensioner bolts 10 — 89

Crankcase ventilation cover assembly bolts 10 — 89

Oil filter adapter bolts 25 18 —

Coolant outlet (front) connector bolts 25 18 —

Air cleaner outlet tube clamps 10 — 89

Accelerator cable bracket 10 — 89

Manifold absolute pressure (MAP) sensor retainer nut 10 — 89

Coil-on-plug retaining bolt 10 — 89

Engine timing plug bolt 20 15 —

Battery tray bolts 12 — 9

Power steering tube bracket nut 13 10 —

Coolant bypass bolt 10 — 89

Belt tensioner bolt 50 37 —

Oil filter cup 33 24 —

Oil pan-to-bellhousing boltsa — — —

Heated oxygen sensor (HO2S) and catalyst monitor sensor wire connector bracket nuts 25 18 —

Bellhousing-to-engine bolts 48 35 —

Bellhousing-to-engine stud bolt 48 35 —

Bellhousing-to-oil pan boltsa — — —

Engine-to-bellhousing stud bolt 48 35 —

Engine front cover-to-oil pan boltsa — — —

Rear main seal mounting plate bolts 10 — 89

Camshaft position (CMP) sensor bolt 7 — 62

Cylinder head temperature (CHT) sensor 12 9 —

Spark plug 15 11 —

Fuel injection supply manifold bolt 18 13 —

Engine vent cover bolt 10 — 89

Pressure plate bolts 32 24 —

General Specifications Item Specification

Displacement 2.3L

No. of cylinders 4

Bore/stroke 87.5/94.0

Firing order 1-3-4-2

Oil pressure (hot @ 2,000 rpm) 29-39 psi 200-268 kPa

Belt tension Refer to Section 303-05.

Oil capacity 4.1 qts. + 0.4 qt. with filter

Cylinder Block

Cylinder bore diameter 87.5-87.53 mm (3.444-3.445 in.)

Cylinder bore maximum out-of-round 0.008 mm (0.0003 in.)

Main bearing bore diameter 57.020-57.038 mm (2.244-2.245 in.)

Head gasket surface flatness 0.1 mm/general 0.05 mm/200 x 200 (0.004 in./general) (0.0019 in./7.87 x 7.87)

Piston

Diameter (1) 87.5-87.51 mm (3.444-3.445 in.)

Diameter (2) 87.51-87.52 mm (3.4452-3.4456 in.)

Diameter (3) 87.52-87.53 mm (3.444-3.446 in.)

Piston-to-bore clearance 0.025-0.045 mm (0.0009-0.0017 in.)

Ring groove width — top 1.203-1.205 mm (0.0473-0.0474 in.)

Ring groove width — 2nd 1.17-1.19 mm (0.0.460-0.0468 in.)

Ring groove width — oil 2.501-2.503 mm (0.0984-0.0985 in.)

Piston skirt coating thickness 0.008-0.020 mm (0.0003-0.0007 in.)

Piston Pin

Diameter 20.995-21.0 mm (0.8266-0.8268 in.)

Length 59.6-60.4 mm (2.346-2.377 in.)

Piston-to-pin clearance 0.008-0.016 mm (0.0003-0.0006 in.)

Pin-to-rod clearance Press fit

Cylinder Head

Valve lift @ zero lash (exhaust) 7.4 mm

Valve lift @ zero lash (intake) 7.9 mm

Valve guide diameter 5.509-5.539 mm (0.216-0.218 in.)

Valve seat width — intake/exhaust 0.99-1.84 mm (0.038-0.072 in.)

Valve seat angle 45 degrees

Valve seat runout 0.075 mm (0.0029 in.)

Valve lash adjuster bore diameter 31.00-31.03 mm (1.220-1.221 in.)

Cam bore diameter 25.015-25.040 mm (0.984-0.985 in.)

Valve

Valve head diameter — intake 34.85-35.15 mm (1.372-1.383 in.)

Valve head diameter — exhaust 29.85-30.15 mm (1.175-1.187 in.)

Valve stem diameter — intake 5.470-5.485 mm (0.2153-0.2159 in.)

Valve stem diameter — exhaust 5.465-5.480 mm (0.2151-0.2157 in.)

Valve stem-to-guide clearance — intake 0.0027 mm (0.0001 in.)

Valve stem-to-guide clearance — exhaust 0.0029 mm (0.00011 in.)

Valve face runout 0.05 mm (0.001 in.)

Valve face angle 45 degrees

Valve Spring — Compression Pressure

Intake and exhaust (installed) 38.667 lbs.

Intake (valve open) 8.9 mm (0.35 in) of lift 97.032 lbs.

Exhaust (valve open) 7.4 mm of lift 93.338 lbs.

Free length 44.92 mm (1.768 in.)

Assembled height 37.9 mm (1.492 in.)

Crankshaft

Main bearing journal diameter 51.980-52.000 mm (2.046-2.047 in.)

Production repair 51.730-51.750 mm (2.036-2.037 in.)

Main bearing clearance 0.019-0.035 mm (0.0007-0.0013 in.)

Connecting rod journal diameter 49.980-50.000 mm (1.967-1.968 in.)

Production repair 49.730-49.750 mm (1.957-1.958 in.)

End play 0.22-0.43 mm (0.008-0.016 in.)

Rings

Width — top 1.17-1.185 mm (0.0460-0.0466 in.)

Width — 2nd 1.197-1.199 mm (0.0471-0.0472 in.)

Width — oil 2.38-2.45 mm (0.093-0.096 in.)

Ring gap (in bore) — top 0.16-0.31 mm (0.006-0.012 in.)

Ring gap (in bore) — 2nd 0.33-0.48 mm (0.012-0.018 in.)

Ring gap (in bore) — oil 0.2-0.7 mm (0.007-0.027 in.)

Valve Tappet

Diameter 30.97-30.98 mm (1.2192-1.2196 in.)

Tappet-to-valve clearance — intake 0.22- 0.28 mm (0.008-0.011 in.)

Tappet-to-valve clearance — exhaust 0.27-0.33 mm (0.010-0.013 in.)

Tappet-to-bore clearance 0.02-0.06 mm (0.0007-0.0023 in.)

Camshaft

Lobe lift — intake 8.24999 mm (0.324 in.)

Lobe lift — exhaust 7.80007 mm (0.307 in.)

Runout (1)a 0.03 mm (0.001 in.)

Thrust clearance 0.09-0.24 mm (0.003-0.009 in.)

Journal diameter 24.96-24.98 mm (0.982-0.983 in.)

Journal-to-bore clearance 0.035-0.080 mm (0.001-0.003 in.)

Connecting Rod

Bearing clearance 0.027-0.052 (0.001-0.002 in.)

Bearing thickness 1.496-1.520 mm (0.058-0.059 in.)

Crank bore diameter 53.025-53.045 mm (2.087-2.088 in.)

Pin bore diameter 20.965-20.985 mm (0.825-0.826 in.)

Length (center to center) 154.8 mm (6.094 in.)

Side clearance 1.95-3.05 mm (0.076-0.120 in.)

Axial clearance 0.14-0.36 mm (0.005-0.014 in.)

a No. 3 Journal — Supported by No. 1 and No. 5 journals.

General Specifications Item Specification

Metal Surface Cleaner F4AZ-19A536-RA WSE-M5B392-A

Silicone Gasket and Sealant F7AZ-19554-EA WSE-M4G323-A4

Super Premium SAE 5W-20 Engine Oil XO-5W20-QSP WSS-M2C153-H

MERPOL® O-Ring Seal Lubricant ESE-M99B144-B

Torque Specifications Description Nm lb-ft lb-in

Camshaft bearing capsa — — —

Coolant outlet connection bolts 10 — 89

Oil pan boltsa — — —

Oil pump-to-engine block bolts 25 18 —

Cylinder head boltsa — — —

Intake manifold bolts 18 13 —

Flywheel bolta — — —

Crankshaft pulley bolta — — —

Crankshaft position sensora — — —

Crankshaft oil seal retainera — — —

A/C compressor mounting bolts 25 18 —

Oil pump sprocket bolt 25 18 —

Knock sensor 20 15 —

Engine plug bolt 20 15 —

Rear engine mounting nut 133 98 —

Front engine mounting nuts 80 59

Motor mount bracket bolts 48 35

Engine roll-restrictor bolts 48 35

Engine-to-bellhousing bolts 48 35 —

Torque converter-to-flywheel nuts 35 26 —

Starter motor mounting bolts 25 18 —

Power steering press line tube nut 20 15 —

Powertrain control module (PCM) wiring connector 6 — 53

Coolant pump bolts 10 — 89

Engine front cover boltsa — — —

Camshaft sprocket bolt 72 53 —

Valve cover bolts 10 — 89

Engine lifting eye bolts 45 33 —

Exhaust gas recirculation (EGR) valve assembly bolts 25 18 —

Generator mounting bolts 25 18 —

Thermostat assembly bolts 10 — 89

Oil pump screen and cover assembly 10 — 89

Exhaust manifold studs 17 13 —

Exhaust manifold-to-cylinder head nuts 54 40 —

Coolant pump pulley bolts 25 18 —

Crankshaft position (CKP) sensor boltsa — — —

Generator A/C mounting bracket bolts 48 35 —

Power steering pump mounting bolts 25 18 —

Engine ground cable-to-cylinder head bolt 10 — 89

Oil level indicator tube bolt 10 — 89

Engine wire harness bulkhead connector bolt 10 — 89

Engine body ground bolt 10 — 89

Engine harness ground PCM connector nut 10 — 89

Accelerator control splash shield 8 — 71

Oil pressure sensor 15 11 —

A/C manifold tube bolt 20 15 —

Exhaust manifold-to-exhaust inlet pipe nuts 40 30 —

Transmission tubes bracket bolt 28 21 —

Oil drain plug 28 21 —

Oil pump chain tensioner bolts 10 — 89

Oil pump chain guide bolts 10 — 89

Timing chain guide bolts 10 — 89

Timing chain tensioner bolts 10 — 89

Crankcase ventilation cover assembly bolts 10 — 89

Oil filter adapter bolts 25 18 —

Coolant outlet (front) connector bolts 25 18 —

Air cleaner outlet tube clamps 10 — 89

Accelerator cable bracket 10 — 89

Manifold absolute pressure (MAP) sensor retainer nut 10 — 89

Coil-on-plug retaining bolt 10 — 89

Engine timing plug bolt 20 15 —

Battery tray bolts 12 — 9

Power steering tube bracket nut 13 10 —

Coolant bypass bolt 10 — 89

Belt tensioner bolt 50 37 —

Oil filter cup 33 24 —

Oil pan-to-bellhousing boltsa — — —

Heated oxygen sensor (HO2S) and catalyst monitor sensor wire connector bracket nuts 25 18 —

Bellhousing-to-engine bolts 48 35 —

Bellhousing-to-engine stud bolt 48 35 —

Bellhousing-to-oil pan boltsa — — —

Engine-to-bellhousing stud bolt 48 35 —

Engine front cover-to-oil pan boltsa — — —

Rear main seal mounting plate bolts 10 — 89

Camshaft position (CMP) sensor bolt 7 — 62

Cylinder head temperature (CHT) sensor 12 9 —

Spark plug 15 11 —

Fuel injection supply manifold bolt 18 13 —

Engine vent cover bolt 10 — 89

Pressure plate bolts 32 24 —

The following users liked this post:

cruz1919 (06-24-2022)

#3

#4

If I'm being honest here, I checked mine for deformities and reused them.

Yes, I know I "shouldn't have" as they are supposed to be Torque-To-Yield. But I wasn't incredibly concerned about them breaking.

The truck might make 100WHP on a good day.

The following users liked this post:

Mediasvi (06-11-2020)

#5

I did get ARP main and rod studs and bolts very pricey, I am under a time limit and need my biz truck back on the road by the 22nd and I want this engine to go another 100,000 miles easy. My opinion is while you have it all apart do it right and because I am doing it myself an extra $100 for bolts is ok.

I have the head back from the machine shop all fixed looking brand new, exhaust valves were out of round, for $295 and the guy who did my short block called tonight letting me know everything is done and I can use standard sizes on everything. He cleaned everything Block, Crank, Rods, Pistons, measured everything, polished the crank and hooned the cylinders for $250

I have a bunch of parts on order and should have everything by next Tuesday. Lucked out and found a Ford dealer with 2 diamond friction washers in stock they were $22

I am replacing the EGR valve, PVC valve, Separator Assembly, Oil pressure sensor, Water Pump, Thermostat, oil pump, timing/oil pump chain, all chain guides, and chain tensioner. Also cleaning out the intake manifold, Air filter box, throttle body...etc Do it while its all apart and do it right and it will serve you well....I hope

I have the head back from the machine shop all fixed looking brand new, exhaust valves were out of round, for $295 and the guy who did my short block called tonight letting me know everything is done and I can use standard sizes on everything. He cleaned everything Block, Crank, Rods, Pistons, measured everything, polished the crank and hooned the cylinders for $250

I have a bunch of parts on order and should have everything by next Tuesday. Lucked out and found a Ford dealer with 2 diamond friction washers in stock they were $22

I am replacing the EGR valve, PVC valve, Separator Assembly, Oil pressure sensor, Water Pump, Thermostat, oil pump, timing/oil pump chain, all chain guides, and chain tensioner. Also cleaning out the intake manifold, Air filter box, throttle body...etc Do it while its all apart and do it right and it will serve you well....I hope

Last edited by Mediasvi; 06-13-2020 at 07:46 AM.

#6

Talking with an engine builder he told me that I could re-use the Main and Rod bolts on this rebuild because they are not torqued to yield bolts and this is just a stock engine rebuild. He said you must replace the Head bolts. This is interesting and it explains why you can find Head bolts for these motors everywhere but not the Main/Rod bolts which you would only really need if you were doing a power upgrade rebuild then you would need better bolts/studs. I will be returning my ARP Main/Rod bolts and cleaning up the stock ones for the rebuild.

#7

Today I was working on cleaning what left to on pistons from the machine and stopped and ordered new pistons. Pistons that have 130,000 miles on them can get so much carbon baked onto them you can not get them clean. Got some Engine Tec pistons from Rock Auto that work fine. Now on to getting these wrist pins pressed out.

#8

Ok, I found this for engine specification so far. If you know of any other info on this please share.2.3 Duratec:

General Specifications Item Specification

Displacement 2.3L

No. of cylinders 4

Bore/stroke 87.5/94.0

Firing order 1-3-4-2

Oil pressure (hot @ 2,000 rpm) 29-39 psi 200-268 kPa

Belt tension Refer to Section 303-05.

Oil capacity 4.1 qts. + 0.4 qt. with filter

Cylinder Block

Cylinder bore diameter 87.5-87.53 mm (3.444-3.445 in.)

Cylinder bore maximum out-of-round 0.008 mm (0.0003 in.)

Main bearing bore diameter 57.020-57.038 mm (2.244-2.245 in.)

Head gasket surface flatness 0.1 mm/general 0.05 mm/200 x 200 (0.004 in./general) (0.0019 in./7.87 x 7.87)

Piston

Diameter (1) 87.5-87.51 mm (3.444-3.445 in.)

Diameter (2) 87.51-87.52 mm (3.4452-3.4456 in.)

Diameter (3) 87.52-87.53 mm (3.444-3.446 in.)

Piston-to-bore clearance 0.025-0.045 mm (0.0009-0.0017 in.)

Ring groove width top 1.203-1.205 mm (0.0473-0.0474 in.)

Ring groove width 2nd 1.17-1.19 mm (0.0.460-0.0468 in.)

Ring groove width oil 2.501-2.503 mm (0.0984-0.0985 in.)

Piston skirt coating thickness 0.008-0.020 mm (0.0003-0.0007 in.)

Piston Pin

Diameter 20.995-21.0 mm (0.8266-0.8268 in.)

Length 59.6-60.4 mm (2.346-2.377 in.)

Piston-to-pin clearance 0.008-0.016 mm (0.0003-0.0006 in.)

Pin-to-rod clearance Press fit

Cylinder Head

Valve lift @ zero lash (exhaust) 7.4 mm

Valve lift @ zero lash (intake) 7.9 mm

Valve guide diameter 5.509-5.539 mm (0.216-0.218 in.)

Valve seat width intake/exhaust 0.99-1.84 mm (0.038-0.072 in.)

Valve seat angle 45 degrees

Valve seat runout 0.075 mm (0.0029 in.)

Valve lash adjuster bore diameter 31.00-31.03 mm (1.220-1.221 in.)

Cam bore diameter 25.015-25.040 mm (0.984-0.985 in.)

Valve

Valve head diameter intake 34.85-35.15 mm (1.372-1.383 in.)

Valve head diameter exhaust 29.85-30.15 mm (1.175-1.187 in.)

Valve stem diameter intake 5.470-5.485 mm (0.2153-0.2159 in.)

Valve stem diameter exhaust 5.465-5.480 mm (0.2151-0.2157 in.)

Valve stem-to-guide clearance intake 0.0027 mm (0.0001 in.)

Valve stem-to-guide clearance exhaust 0.0029 mm (0.00011 in.)

Valve face runout 0.05 mm (0.001 in.)

Valve face angle 45 degrees

Valve Spring Compression Pressure

Intake and exhaust (installed) 38.667 lbs.

Intake (valve open) 8.9 mm (0.35 in) of lift 97.032 lbs.

Exhaust (valve open) 7.4 mm of lift 93.338 lbs.

Free length 44.92 mm (1.768 in.)

Assembled height 37.9 mm (1.492 in.)

Crankshaft

Main bearing journal diameter 51.980-52.000 mm (2.046-2.047 in.)

Production repair 51.730-51.750 mm (2.036-2.037 in.)

Main bearing clearance 0.019-0.035 mm (0.0007-0.0013 in.)

Connecting rod journal diameter 49.980-50.000 mm (1.967-1.968 in.)

Production repair 49.730-49.750 mm (1.957-1.958 in.)

End play 0.22-0.43 mm (0.008-0.016 in.)

Rings

Width top 1.17-1.185 mm (0.0460-0.0466 in.)

Width 2nd 1.197-1.199 mm (0.0471-0.0472 in.)

Width oil 2.38-2.45 mm (0.093-0.096 in.)

Ring gap (in bore) top 0.16-0.31 mm (0.006-0.012 in.)

Ring gap (in bore) 2nd 0.33-0.48 mm (0.012-0.018 in.)

Ring gap (in bore) oil 0.2-0.7 mm (0.007-0.027 in.)

Valve Tappet

Diameter 30.97-30.98 mm (1.2192-1.2196 in.)

Tappet-to-valve clearance intake 0.22- 0.28 mm (0.008-0.011 in.)

Tappet-to-valve clearance exhaust 0.27-0.33 mm (0.010-0.013 in.)

Tappet-to-bore clearance 0.02-0.06 mm (0.0007-0.0023 in.)

Camshaft

Lobe lift intake 8.24999 mm (0.324 in.)

Lobe lift exhaust 7.80007 mm (0.307 in.)

Runout (1)a 0.03 mm (0.001 in.)

Thrust clearance 0.09-0.24 mm (0.003-0.009 in.)

Journal diameter 24.96-24.98 mm (0.982-0.983 in.)

Journal-to-bore clearance 0.035-0.080 mm (0.001-0.003 in.)

Connecting Rod

Bearing clearance 0.027-0.052 (0.001-0.002 in.)

Bearing thickness 1.496-1.520 mm (0.058-0.059 in.)

Crank bore diameter 53.025-53.045 mm (2.087-2.088 in.)

Pin bore diameter 20.965-20.985 mm (0.825-0.826 in.)

Length (center to center) 154.8 mm (6.094 in.)

Side clearance 1.95-3.05 mm (0.076-0.120 in.)

Axial clearance 0.14-0.36 mm (0.005-0.014 in.)

a No. 3 Journal Supported by No. 1 and No. 5 journals.

General Specifications Item Specification

Metal Surface Cleaner F4AZ-19A536-RA WSE-M5B392-A

Silicone Gasket and Sealant F7AZ-19554-EA WSE-M4G323-A4

Super Premium SAE 5W-20 Engine Oil XO-5W20-QSP WSS-M2C153-H

MERPOL® O-Ring Seal Lubricant ESE-M99B144-B

Torque Specifications Description Nm lb-ft lb-in

Camshaft bearing capsa

Coolant outlet connection bolts 10 89

Oil pan boltsa

Oil pump-to-engine block bolts 25 18

Cylinder head boltsa

Intake manifold bolts 18 13

Flywheel bolta

Crankshaft pulley bolta

Crankshaft position sensora

Crankshaft oil seal retainera

A/C compressor mounting bolts 25 18

Oil pump sprocket bolt 25 18

Knock sensor 20 15

Engine plug bolt 20 15

Rear engine mounting nut 133 98

Front engine mounting nuts 80 59

Motor mount bracket bolts 48 35

Engine roll-restrictor bolts 48 35

Engine-to-bellhousing bolts 48 35

Torque converter-to-flywheel nuts 35 26

Starter motor mounting bolts 25 18

Power steering press line tube nut 20 15

Powertrain control module (PCM) wiring connector 6 53

Coolant pump bolts 10 89

Engine front cover boltsa

Camshaft sprocket bolt 72 53

Valve cover bolts 10 89

Engine lifting eye bolts 45 33

Exhaust gas recirculation (EGR) valve assembly bolts 25 18

Generator mounting bolts 25 18

Thermostat assembly bolts 10 89

Oil pump screen and cover assembly 10 89

Exhaust manifold studs 17 13

Exhaust manifold-to-cylinder head nuts 54 40

Coolant pump pulley bolts 25 18

Crankshaft position (CKP) sensor boltsa

Generator A/C mounting bracket bolts 48 35

Power steering pump mounting bolts 25 18

Engine ground cable-to-cylinder head bolt 10 89

Oil level indicator tube bolt 10 89

Engine wire harness bulkhead connector bolt 10 89

Engine body ground bolt 10 89

Engine harness ground PCM connector nut 10 89

Accelerator control splash shield 8 71

Oil pressure sensor 15 11

A/C manifold tube bolt 20 15

Exhaust manifold-to-exhaust inlet pipe nuts 40 30

Transmission tubes bracket bolt 28 21

Oil drain plug 28 21

Oil pump chain tensioner bolts 10 89

Oil pump chain guide bolts 10 89

Timing chain guide bolts 10 89

Timing chain tensioner bolts 10 89

Crankcase ventilation cover assembly bolts 10 89

Oil filter adapter bolts 25 18

Coolant outlet (front) connector bolts 25 18

Air cleaner outlet tube clamps 10 89

Accelerator cable bracket 10 89

Manifold absolute pressure (MAP) sensor retainer nut 10 89

Coil-on-plug retaining bolt 10 89

Engine timing plug bolt 20 15

Battery tray bolts 12 9

Power steering tube bracket nut 13 10

Coolant bypass bolt 10 89

Belt tensioner bolt 50 37

Oil filter cup 33 24

Oil pan-to-bellhousing boltsa

Heated oxygen sensor (HO2S) and catalyst monitor sensor wire connector bracket nuts 25 18

Bellhousing-to-engine bolts 48 35

Bellhousing-to-engine stud bolt 48 35

Bellhousing-to-oil pan boltsa

Engine-to-bellhousing stud bolt 48 35

Engine front cover-to-oil pan boltsa

Rear main seal mounting plate bolts 10 89

Camshaft position (CMP) sensor bolt 7 62

Cylinder head temperature (CHT) sensor 12 9

Spark plug 15 11

Fuel injection supply manifold bolt 18 13

Engine vent cover bolt 10 89

Pressure plate bolts 32 24

General Specifications Item Specification

Displacement 2.3L

No. of cylinders 4

Bore/stroke 87.5/94.0

Firing order 1-3-4-2

Oil pressure (hot @ 2,000 rpm) 29-39 psi 200-268 kPa

Belt tension Refer to Section 303-05.

Oil capacity 4.1 qts. + 0.4 qt. with filter

Cylinder Block

Cylinder bore diameter 87.5-87.53 mm (3.444-3.445 in.)

Cylinder bore maximum out-of-round 0.008 mm (0.0003 in.)

Main bearing bore diameter 57.020-57.038 mm (2.244-2.245 in.)

Head gasket surface flatness 0.1 mm/general 0.05 mm/200 x 200 (0.004 in./general) (0.0019 in./7.87 x 7.87)

Piston

Diameter (1) 87.5-87.51 mm (3.444-3.445 in.)

Diameter (2) 87.51-87.52 mm (3.4452-3.4456 in.)

Diameter (3) 87.52-87.53 mm (3.444-3.446 in.)

Piston-to-bore clearance 0.025-0.045 mm (0.0009-0.0017 in.)

Ring groove width top 1.203-1.205 mm (0.0473-0.0474 in.)

Ring groove width 2nd 1.17-1.19 mm (0.0.460-0.0468 in.)

Ring groove width oil 2.501-2.503 mm (0.0984-0.0985 in.)

Piston skirt coating thickness 0.008-0.020 mm (0.0003-0.0007 in.)

Piston Pin

Diameter 20.995-21.0 mm (0.8266-0.8268 in.)

Length 59.6-60.4 mm (2.346-2.377 in.)

Piston-to-pin clearance 0.008-0.016 mm (0.0003-0.0006 in.)

Pin-to-rod clearance Press fit

Cylinder Head

Valve lift @ zero lash (exhaust) 7.4 mm

Valve lift @ zero lash (intake) 7.9 mm

Valve guide diameter 5.509-5.539 mm (0.216-0.218 in.)

Valve seat width intake/exhaust 0.99-1.84 mm (0.038-0.072 in.)

Valve seat angle 45 degrees

Valve seat runout 0.075 mm (0.0029 in.)

Valve lash adjuster bore diameter 31.00-31.03 mm (1.220-1.221 in.)

Cam bore diameter 25.015-25.040 mm (0.984-0.985 in.)

Valve

Valve head diameter intake 34.85-35.15 mm (1.372-1.383 in.)

Valve head diameter exhaust 29.85-30.15 mm (1.175-1.187 in.)

Valve stem diameter intake 5.470-5.485 mm (0.2153-0.2159 in.)

Valve stem diameter exhaust 5.465-5.480 mm (0.2151-0.2157 in.)

Valve stem-to-guide clearance intake 0.0027 mm (0.0001 in.)

Valve stem-to-guide clearance exhaust 0.0029 mm (0.00011 in.)

Valve face runout 0.05 mm (0.001 in.)

Valve face angle 45 degrees

Valve Spring Compression Pressure

Intake and exhaust (installed) 38.667 lbs.

Intake (valve open) 8.9 mm (0.35 in) of lift 97.032 lbs.

Exhaust (valve open) 7.4 mm of lift 93.338 lbs.

Free length 44.92 mm (1.768 in.)

Assembled height 37.9 mm (1.492 in.)

Crankshaft

Main bearing journal diameter 51.980-52.000 mm (2.046-2.047 in.)

Production repair 51.730-51.750 mm (2.036-2.037 in.)

Main bearing clearance 0.019-0.035 mm (0.0007-0.0013 in.)

Connecting rod journal diameter 49.980-50.000 mm (1.967-1.968 in.)

Production repair 49.730-49.750 mm (1.957-1.958 in.)

End play 0.22-0.43 mm (0.008-0.016 in.)

Rings

Width top 1.17-1.185 mm (0.0460-0.0466 in.)

Width 2nd 1.197-1.199 mm (0.0471-0.0472 in.)

Width oil 2.38-2.45 mm (0.093-0.096 in.)

Ring gap (in bore) top 0.16-0.31 mm (0.006-0.012 in.)

Ring gap (in bore) 2nd 0.33-0.48 mm (0.012-0.018 in.)

Ring gap (in bore) oil 0.2-0.7 mm (0.007-0.027 in.)

Valve Tappet

Diameter 30.97-30.98 mm (1.2192-1.2196 in.)

Tappet-to-valve clearance intake 0.22- 0.28 mm (0.008-0.011 in.)

Tappet-to-valve clearance exhaust 0.27-0.33 mm (0.010-0.013 in.)

Tappet-to-bore clearance 0.02-0.06 mm (0.0007-0.0023 in.)

Camshaft

Lobe lift intake 8.24999 mm (0.324 in.)

Lobe lift exhaust 7.80007 mm (0.307 in.)

Runout (1)a 0.03 mm (0.001 in.)

Thrust clearance 0.09-0.24 mm (0.003-0.009 in.)

Journal diameter 24.96-24.98 mm (0.982-0.983 in.)

Journal-to-bore clearance 0.035-0.080 mm (0.001-0.003 in.)

Connecting Rod

Bearing clearance 0.027-0.052 (0.001-0.002 in.)

Bearing thickness 1.496-1.520 mm (0.058-0.059 in.)

Crank bore diameter 53.025-53.045 mm (2.087-2.088 in.)

Pin bore diameter 20.965-20.985 mm (0.825-0.826 in.)

Length (center to center) 154.8 mm (6.094 in.)

Side clearance 1.95-3.05 mm (0.076-0.120 in.)

Axial clearance 0.14-0.36 mm (0.005-0.014 in.)

a No. 3 Journal Supported by No. 1 and No. 5 journals.

General Specifications Item Specification

Metal Surface Cleaner F4AZ-19A536-RA WSE-M5B392-A

Silicone Gasket and Sealant F7AZ-19554-EA WSE-M4G323-A4

Super Premium SAE 5W-20 Engine Oil XO-5W20-QSP WSS-M2C153-H

MERPOL® O-Ring Seal Lubricant ESE-M99B144-B

Torque Specifications Description Nm lb-ft lb-in

Camshaft bearing capsa

Coolant outlet connection bolts 10 89

Oil pan boltsa

Oil pump-to-engine block bolts 25 18

Cylinder head boltsa

Intake manifold bolts 18 13

Flywheel bolta

Crankshaft pulley bolta

Crankshaft position sensora

Crankshaft oil seal retainera

A/C compressor mounting bolts 25 18

Oil pump sprocket bolt 25 18

Knock sensor 20 15

Engine plug bolt 20 15

Rear engine mounting nut 133 98

Front engine mounting nuts 80 59

Motor mount bracket bolts 48 35

Engine roll-restrictor bolts 48 35

Engine-to-bellhousing bolts 48 35

Torque converter-to-flywheel nuts 35 26

Starter motor mounting bolts 25 18

Power steering press line tube nut 20 15

Powertrain control module (PCM) wiring connector 6 53

Coolant pump bolts 10 89

Engine front cover boltsa

Camshaft sprocket bolt 72 53

Valve cover bolts 10 89

Engine lifting eye bolts 45 33

Exhaust gas recirculation (EGR) valve assembly bolts 25 18

Generator mounting bolts 25 18

Thermostat assembly bolts 10 89

Oil pump screen and cover assembly 10 89

Exhaust manifold studs 17 13

Exhaust manifold-to-cylinder head nuts 54 40

Coolant pump pulley bolts 25 18

Crankshaft position (CKP) sensor boltsa

Generator A/C mounting bracket bolts 48 35

Power steering pump mounting bolts 25 18

Engine ground cable-to-cylinder head bolt 10 89

Oil level indicator tube bolt 10 89

Engine wire harness bulkhead connector bolt 10 89

Engine body ground bolt 10 89

Engine harness ground PCM connector nut 10 89

Accelerator control splash shield 8 71

Oil pressure sensor 15 11

A/C manifold tube bolt 20 15

Exhaust manifold-to-exhaust inlet pipe nuts 40 30

Transmission tubes bracket bolt 28 21

Oil drain plug 28 21

Oil pump chain tensioner bolts 10 89

Oil pump chain guide bolts 10 89

Timing chain guide bolts 10 89

Timing chain tensioner bolts 10 89

Crankcase ventilation cover assembly bolts 10 89

Oil filter adapter bolts 25 18

Coolant outlet (front) connector bolts 25 18

Air cleaner outlet tube clamps 10 89

Accelerator cable bracket 10 89

Manifold absolute pressure (MAP) sensor retainer nut 10 89

Coil-on-plug retaining bolt 10 89

Engine timing plug bolt 20 15

Battery tray bolts 12 9

Power steering tube bracket nut 13 10

Coolant bypass bolt 10 89

Belt tensioner bolt 50 37

Oil filter cup 33 24

Oil pan-to-bellhousing boltsa

Heated oxygen sensor (HO2S) and catalyst monitor sensor wire connector bracket nuts 25 18

Bellhousing-to-engine bolts 48 35

Bellhousing-to-engine stud bolt 48 35

Bellhousing-to-oil pan boltsa

Engine-to-bellhousing stud bolt 48 35

Engine front cover-to-oil pan boltsa

Rear main seal mounting plate bolts 10 89

Camshaft position (CMP) sensor bolt 7 62

Cylinder head temperature (CHT) sensor 12 9

Spark plug 15 11

Fuel injection supply manifold bolt 18 13

Engine vent cover bolt 10 89

Pressure plate bolts 32 24

#9

#10

Today I removed the pistons from the connecting rods. I just used a vise and some 3/8 allthread. I grinded a 1/2" nut to fit through the piston hole. If you do this make sure to align the wrist pin so it does not come out and scrape on the vise. Also make sure you do not scrape the piston hole if you want to use your pistons again. Make sure to use some oil on the nut you tighten to pull the pin out.

I screwed the vise to the wood.

Make sure to center wrist pin if you want to use it again.

Center the ground down nut or what ever you use so you do not scratch the piston hole.

I screwed the vise to the wood.

Make sure to center wrist pin if you want to use it again.

Center the ground down nut or what ever you use so you do not scratch the piston hole.

Last edited by Mediasvi; 06-14-2020 at 08:36 PM.

#11

#12

Cleaning out the intake manfold it is crazy how much oil coating is all inside it. I am guessing you need to change out the pvc valve and the pvc assembly separater quit often. Never seen anything like this having the crank case go into the intake manfold like this. These EFI/Emission engines really are something and need to be handled with kid gloves or their cheap parts will break down.

To clean it out I took all the sensors off the manifold and removed the PVC tube header. And then just use Gunk Engine cleaner. I just spray it in all the holes shake it a bit and then raise it with water, it works pretty good but takes about 3 cans of the gunk.

To clean it out I took all the sensors off the manifold and removed the PVC tube header. And then just use Gunk Engine cleaner. I just spray it in all the holes shake it a bit and then raise it with water, it works pretty good but takes about 3 cans of the gunk.

Last edited by Mediasvi; 06-15-2020 at 04:58 PM.

#13

Put new pistons on

I made a Device to help put the new pistons on the rods. Getting the measurement right was the hardest thing. With my new pistons there was 4mm of play 2mm on each side the the rod when it was installed on the piston. With the divice I just needed to get the measurement set once and then do them all.

#14

Here are some pictures of the short block build. All stock sized bearings for mains and rods. It went together easy.

Here are the main bearings in the block. No notch to make it easy to center the bearing.

Here are the main bearings in the main girdle. No notch to easily center the bearing.

I use anti seize grease on the bolts and some on the block where the bolt will bolt down on.

New pistons are the way to go after 130,000. The pistons were under $20 a each from Rock Auto. The are made by Engine Tech and conr with wrist pin. I used Moley rings. Its just a stock rebuild so they should do just fine.

Make sure to prime the oil pump. I use my cordless drill driver to spin the pump as I added oil until I saw oil at the filter. Then I just install the oil filter so I can turn the engine over. The filter has to come off before installing the engine.

Here are the main bearings in the block. No notch to make it easy to center the bearing.

Here are the main bearings in the main girdle. No notch to easily center the bearing.

I use anti seize grease on the bolts and some on the block where the bolt will bolt down on.

New pistons are the way to go after 130,000. The pistons were under $20 a each from Rock Auto. The are made by Engine Tech and conr with wrist pin. I used Moley rings. Its just a stock rebuild so they should do just fine.

Make sure to prime the oil pump. I use my cordless drill driver to spin the pump as I added oil until I saw oil at the filter. Then I just install the oil filter so I can turn the engine over. The filter has to come off before installing the engine.

The following 2 users liked this post by Mediasvi:

koolhandlinc (09-27-2020),

Rock304 (06-23-2020)

#16

#17

I installed the rebuilt motor and tranny bolted together which was real easy. Have to have a load leveler attached to the hoist.

Today I should be able to start it up and break it in.

But before I put the valve cover on I am going to fill up the engine with oil and crank it over with the starter, no plug wires hooked up, until I see oil in the cam bearings. Then I am going to put the valve cover on and fill the tranny and turn over the engine again with the starter to fill up the tranny. I will have my battery jumped to a running car battery.

Today I should be able to start it up and break it in.

But before I put the valve cover on I am going to fill up the engine with oil and crank it over with the starter, no plug wires hooked up, until I see oil in the cam bearings. Then I am going to put the valve cover on and fill the tranny and turn over the engine again with the starter to fill up the tranny. I will have my battery jumped to a running car battery.

#18

Main, Rod, Head Torque 2.3L DuraTech

Main Cap bolts 32ft/lb and then rotate 180 deg

Rod bolts 21ft/lb then rotate 90 deg

Head bolts I did 20ft/lb - 33ft/lb - rotate 90 deg - rotate another 90 deg

I reused my main and rod bolts but not the head bolts. You can reuse them once but never reuse Head bolts.

Rod bolts 21ft/lb then rotate 90 deg

Head bolts I did 20ft/lb - 33ft/lb - rotate 90 deg - rotate another 90 deg

I reused my main and rod bolts but not the head bolts. You can reuse them once but never reuse Head bolts.

The following users liked this post:

koolhandlinc (09-27-2020)

#19

The engine and tranny are all done and installed. 20 minute brake in with cheap oil went perfect idle,1000, 1500, 2000, 2500 rpm each held for a few minutes and after 20min change the oil with 5W-20 Mobile 1 and a new filter. These Duratec engines really need to be maintained well to go behond 100,000 miles with little problems. The PVC valve and assembly must be maintained or your whole intake well get full of oil and cause your pistons and valves to be coated with carbon. I will be changing the PVC and cleaning the assembly every 6000 miles going farword.

If you have any questions just ask.

If you have any questions just ask.

#23

For anyone rebuilding one of these engines, it may not be necessary to press out the wrist pins.

Most are interference fit on the piston when cold and become free floating when the engine is up to temp.

Immersing the piston in boiling water for a bit of time or using a heat gun to warm up the piston should allow the wrist pin to easily come out.

Most are interference fit on the piston when cold and become free floating when the engine is up to temp.

Immersing the piston in boiling water for a bit of time or using a heat gun to warm up the piston should allow the wrist pin to easily come out.

The following users liked this post:

Mediasvi (09-06-2020)

#25

ENGINETECH P50344

https://www.rockauto.com/en/moreinfo...42564&jsn=1060