Cam synchronizer replacement

#1

#2

#4

#5

Step on and Step off pertain to the type of wire connector, Ford changed it but not sure when.

Call a Ford parts dealer with your VIN, and get part number for your VIN, then you can cross reference it.

I think a Step off(without step) connector will work with both step on and step off.......I think.

If you want to check it yourself pull of the connector and look at the sensor end(female), the step off will be the same size all the way front to back.

Step on will be smaller towards the back

Cam sensor also come in 2 wire and 3 wire versions, you need to make sure replacement matches your harness, 2 or 3 wires, they are not interchangeable

Call a Ford parts dealer with your VIN, and get part number for your VIN, then you can cross reference it.

I think a Step off(without step) connector will work with both step on and step off.......I think.

If you want to check it yourself pull of the connector and look at the sensor end(female), the step off will be the same size all the way front to back.

Step on will be smaller towards the back

Cam sensor also come in 2 wire and 3 wire versions, you need to make sure replacement matches your harness, 2 or 3 wires, they are not interchangeable

Last edited by RonD; 11-21-2015 at 10:08 AM.

#8

You will need to get a new bolt, lol.

To get the rounded one out you will need a "grip-bolt" type socket

Google: grip bolt extractor

Or damaged bolt remover

They basically dig into rounded head when turned counter-clockwise(loosening bolt), you often tap them in place with hammer to get better grip

You can also get similar design but instead of socket wrench you can use an open end or box wrench on it.

To get the rounded one out you will need a "grip-bolt" type socket

Google: grip bolt extractor

Or damaged bolt remover

They basically dig into rounded head when turned counter-clockwise(loosening bolt), you often tap them in place with hammer to get better grip

You can also get similar design but instead of socket wrench you can use an open end or box wrench on it.

#9

#10

#11

#12

Never read SHTFT ??

STFT 1

STFT 2

Is all there is on a V engine, 2 banks

These are dwell time(open time) for fuel injectors

There is LTFT(long term fuel trim) that is just used when engine is in open loop, but is based on averages STFTs

What brand of scanner is it?

As far as I know the computer is in Open Loop or Closed Loop, one bank not working would put computer in Open Loop not just that bank

And CEL would be on if O2 sensor wasn't working

STFT 1

STFT 2

Is all there is on a V engine, 2 banks

These are dwell time(open time) for fuel injectors

There is LTFT(long term fuel trim) that is just used when engine is in open loop, but is based on averages STFTs

What brand of scanner is it?

As far as I know the computer is in Open Loop or Closed Loop, one bank not working would put computer in Open Loop not just that bank

And CEL would be on if O2 sensor wasn't working

#13

I worked that issue out. I will do further research.

I wanna know if i did the synch right though.

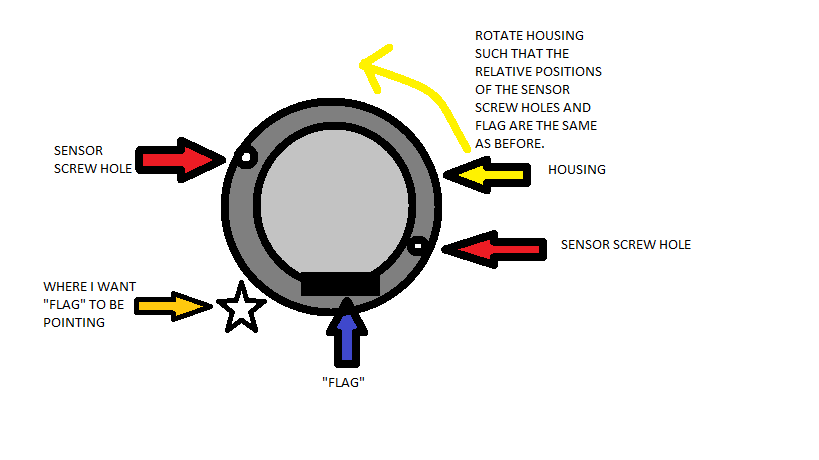

I made sure the relative position between the sensor and the "flag" was exactly the same as before, using reason I figured that the orientation of the HOUSING was not important as long as the sensor is reading the same position as before.... in other words, if I was off a tooth, rotate the HOUSING, not the gear (so I don't have to remove it again) so that the flag aligns with the mark i put on the new housing correlating to the old mark on the old synchro. In other words, the entire assembly is oriented about 30 degrees clockwise from where it used to be in order to make sure the flag is in the same spot in relation to the sensor magnet.

Is this okay? Ive driven around town with no strange noises, no lack of power, spark advance/retard (read from scanner) seems to operate as before, no CELS, still have oil pressure.

I wanna know if i did the synch right though.

I made sure the relative position between the sensor and the "flag" was exactly the same as before, using reason I figured that the orientation of the HOUSING was not important as long as the sensor is reading the same position as before.... in other words, if I was off a tooth, rotate the HOUSING, not the gear (so I don't have to remove it again) so that the flag aligns with the mark i put on the new housing correlating to the old mark on the old synchro. In other words, the entire assembly is oriented about 30 degrees clockwise from where it used to be in order to make sure the flag is in the same spot in relation to the sensor magnet.

Is this okay? Ive driven around town with no strange noises, no lack of power, spark advance/retard (read from scanner) seems to operate as before, no CELS, still have oil pressure.

#15

CPS will give you a CEL if it isn't able to time injectors and spark correctly.

CKP(crank position) sensor tells computer when #1 cylinder is at TDC, but this can be TDC compression stroke or TDC exhaust stroke.

But with Waste spark system and batch fire fuel injection this didn't matter.

Computer could even run Sequential fuel injection with just CKP pulse by testing power gain/loss when opening #1 injector, then remember which TDC added power and skip every other #1 TDC to get sequential injection working with Firing order.

CPS was added to fine tune this process, CPS rotates at half the RPMs of crank, and computer "learns" the best spark and injector timing from CPS and repeats it.

As long as CPS is close to crank timing computer will make it's own adjustments.

If CPS is off you will get lower MPG and often rough engine operation at times.

Computer will also turn on CEL to tell you CPS and CKP sensors are not in sync.

CKP(crank position) sensor tells computer when #1 cylinder is at TDC, but this can be TDC compression stroke or TDC exhaust stroke.

But with Waste spark system and batch fire fuel injection this didn't matter.

Computer could even run Sequential fuel injection with just CKP pulse by testing power gain/loss when opening #1 injector, then remember which TDC added power and skip every other #1 TDC to get sequential injection working with Firing order.

CPS was added to fine tune this process, CPS rotates at half the RPMs of crank, and computer "learns" the best spark and injector timing from CPS and repeats it.

As long as CPS is close to crank timing computer will make it's own adjustments.

If CPS is off you will get lower MPG and often rough engine operation at times.

Computer will also turn on CEL to tell you CPS and CKP sensors are not in sync.

#16

CPS will give you a CEL if it isn't able to time injectors and spark correctly.

CKP(crank position) sensor tells computer when #1 cylinder is at TDC, but this can be TDC compression stroke or TDC exhaust stroke.

But with Waste spark system and batch fire fuel injection this didn't matter.

Computer could even run Sequential fuel injection with just CKP pulse by testing power gain/loss when opening #1 injector, then remember which TDC added power and skip every other #1 TDC to get sequential injection working with Firing order.

CPS was added to fine tune this process, CPS rotates at half the RPMs of crank, and computer "learns" the best spark and injector timing from CPS and repeats it.

As long as CPS is close to crank timing computer will make it's own adjustments.

If CPS is off you will get lower MPG and often rough engine operation at times.

Computer will also turn on CEL to tell you CPS and CKP sensors are not in sync.

CKP(crank position) sensor tells computer when #1 cylinder is at TDC, but this can be TDC compression stroke or TDC exhaust stroke.

But with Waste spark system and batch fire fuel injection this didn't matter.

Computer could even run Sequential fuel injection with just CKP pulse by testing power gain/loss when opening #1 injector, then remember which TDC added power and skip every other #1 TDC to get sequential injection working with Firing order.

CPS was added to fine tune this process, CPS rotates at half the RPMs of crank, and computer "learns" the best spark and injector timing from CPS and repeats it.

As long as CPS is close to crank timing computer will make it's own adjustments.

If CPS is off you will get lower MPG and often rough engine operation at times.

Computer will also turn on CEL to tell you CPS and CKP sensors are not in sync.

I appreciate the info though. You seem very knowleadgeable on rangers. I wish my ranger knowledge was like my honda knowledge.....

#18

#19

so why does EVERY forum show people saying they had to pull out and put back in their synchro multiple times in order to get it "lined up right"? Why didn't they just rotate the housing like I did? Surely im not the first person in history to think of this remedy.

#20

Thread

Thread Starter

Forum

Replies

Last Post

For Sale: comp cam 410 cam and pushrods-NY

destroyer000

OLD - Engine & Drivetrain

7

06-07-2016 08:05 PM