What all goes into Installing a turbo?

#1

#2

Fitting a turbo into engine bay is the hard part, and the "plumbing", larger air tubes.

Super charger, IMO, is easier, and has more stable power curve, but is limited in power

This power limit only applies if you are rebuilding the engine to handle extra power from forced induction, for either you need to limit added power so you don't break the stock engine parts.

How much power to add is the question?

And the answer is unknown, when it breaks you know it was too much

Turbos 'spool up' as exhaust flow increases, so there is "turbo lag" before you feel the extra power.

Super chargers have direct RPM power, so very predictable at any RPM

Super charger, IMO, is easier, and has more stable power curve, but is limited in power

This power limit only applies if you are rebuilding the engine to handle extra power from forced induction, for either you need to limit added power so you don't break the stock engine parts.

How much power to add is the question?

And the answer is unknown, when it breaks you know it was too much

Turbos 'spool up' as exhaust flow increases, so there is "turbo lag" before you feel the extra power.

Super chargers have direct RPM power, so very predictable at any RPM

#3

Are you planning on 1 or 2 turbos? This is a V6 engine so you can either run 2 small turbos off of each bank of cylinders or run the exhaust from both banks together into 1 larger turbo. The twin turbo option will be more efficient and will provide more low end torque but will also be more complex and more expensive.

Whichever you choose, you'll need to make substantial changes go to your exhaust manifolds and may even need to fabricate custom parts. If you can find others who've installed turbos on this engine you can find out what parts options exist. Frankly, I'm more experienced with the 2.3 L turbo and 5.9 L turbo, not the V6 motors.

No matter what, your stock ECU isn't going to know what to do with the turbo so you'll need to find some other engine management system to control fuel and spark. There are various aftermarket options and you'll have to do some research to see what might work best. I've had success with Megasquirt, which is customizable to virtually any engine and fully programmsble with a laptop and easy to use software. Expect to apend at least $1,000 for the complete system. Again, if you can contact others who've done this turbo 3.0 conversion, they may know some cheaper (or simpler) options.

Additionally, you'll almost certainly need to upgrade the fuel injectors and maybe the fuel pump.

Turbos are oli cooled so it will be necessary to run oil cooling lines to and from each. Many turbos are also water cooled so water lines will be needed.

Even assuming modest boost levels for small horsepower gains, you'll need a wastegate for each turbo and a bypass or blow off valve along with the associated hoses and plumbing.

Your stock 3.0 is rated at 155 hp so I'm guessing that about 200 hp is what you can expect with modest boost and no intercooler. If you're planning on nudging the boost up a bit for real power gains, then an intercooler becomes mandatory. That's a whole new pile of parts, along with a list of complications and issues. Also, I don't know how much power your engine and driveline can reliably handle. I'm sure there are other members of this forum who do know the answer.

Hope this helps a bit.

Whichever you choose, you'll need to make substantial changes go to your exhaust manifolds and may even need to fabricate custom parts. If you can find others who've installed turbos on this engine you can find out what parts options exist. Frankly, I'm more experienced with the 2.3 L turbo and 5.9 L turbo, not the V6 motors.

No matter what, your stock ECU isn't going to know what to do with the turbo so you'll need to find some other engine management system to control fuel and spark. There are various aftermarket options and you'll have to do some research to see what might work best. I've had success with Megasquirt, which is customizable to virtually any engine and fully programmsble with a laptop and easy to use software. Expect to apend at least $1,000 for the complete system. Again, if you can contact others who've done this turbo 3.0 conversion, they may know some cheaper (or simpler) options.

Additionally, you'll almost certainly need to upgrade the fuel injectors and maybe the fuel pump.

Turbos are oli cooled so it will be necessary to run oil cooling lines to and from each. Many turbos are also water cooled so water lines will be needed.

Even assuming modest boost levels for small horsepower gains, you'll need a wastegate for each turbo and a bypass or blow off valve along with the associated hoses and plumbing.

Your stock 3.0 is rated at 155 hp so I'm guessing that about 200 hp is what you can expect with modest boost and no intercooler. If you're planning on nudging the boost up a bit for real power gains, then an intercooler becomes mandatory. That's a whole new pile of parts, along with a list of complications and issues. Also, I don't know how much power your engine and driveline can reliably handle. I'm sure there are other members of this forum who do know the answer.

Hope this helps a bit.

Last edited by hbar; 06-19-2019 at 05:05 PM.

#4

#5

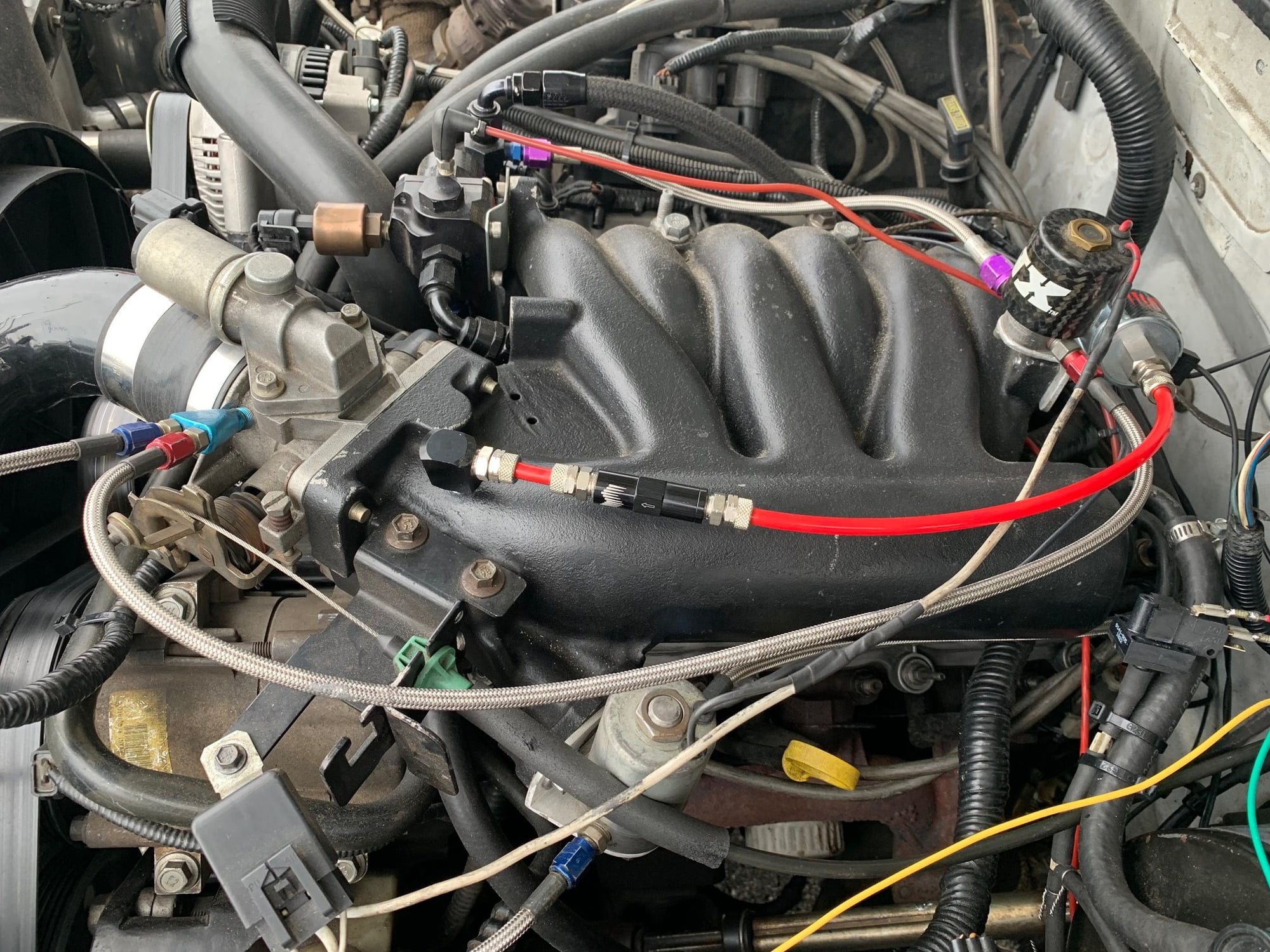

Preparing 3.0L for Bigger Turbo

Gapped 2nd ring to .025

Gapped top ring to .024

ARP Rod bolts and resized ends

twin 255 Walbro 2nd pump triggered by 5psi boost switch and driven by Kenne Bell Boost a pump

Have updated a 2006 Taurus 59k mile 425.00 LKQ engine Vin"U" with ARP 5/16 Rod bolts. Had the rods resized for higher tq specs with the new bolts and file fit rings to .024 top and .025 2nd ring to prevent ring butting at higher cylinder temperatures. I have broken 2 rod bolts in the last 50k miles causing some fire ball type explosions but was using NOS @ 25 psi for over 10 seconds both times.

Thread

Thread Starter

Forum

Replies

Last Post