I have been dreaming

#1

I have been dreaming

of puting a 8.8 ifs diff under the front of my ranger, it looks to be alot better built than the d35, the cv's bolt on instead of push in c-clip

the tube looks like it bolt on instead of just press in, i think it has 28 splines instead of 27 like the d 35

its the same diff thats in the new raptors

befor you say not enough room... I believe it will fit in my case, first I have an RCD lift so that gives me 5 more inches of up and down room

I also plan on gettin the dixon bros kit so it would be 4.5 inches wider per side, so I think the cv's would have enough room (not hit coilovers)

two of the mounts on the 8.8 are the same style mounts as on the d35

here are some comparison pics

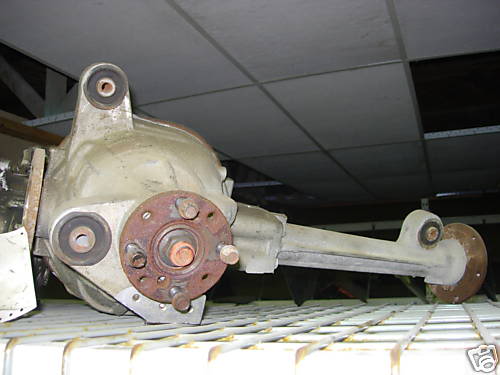

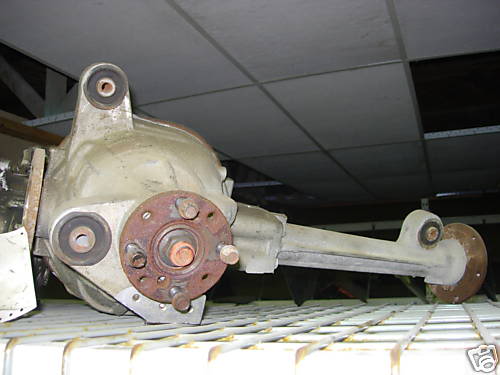

8.8

d35

notice on the 8.8 the mount on top of the diff is closer to the edge with the diff cover than on the d35, so I know I have enough room on the diff cover side

the mount is also set higher on the diff than on the tube (more so than on the d35)

this makes me think that I can use the stock mount for the diff side and use the rcd drop bracket on the tube side

but enough with the quessing, so today I stoped by the ford dealership and crawled under an f150 with a tape in my hand...

from the center of the mount on top of the diff to the bottom of the diff it is 12 inches

on my ranger from the stock mount to the bottom of the diff is 14 inches (including rcd drop bracket)

wich is good because the d35 practicaly sits on top of the rcd cross member, so I have enough room up and down

the 8.8 is 12 inches from diff cover to driveshaft flange, that is the same as the d35 so I may be able to use my superlift drive shaft (or get one that is the same length)

of course I would have to get the tube side shortend the 8.8 is 30 inches wide and the d35 is about 21

so does anybody know where I can send the tube to get it shortend??? or have one made?

think I could get some cv's custom made to go from the 8.8 bolt on side and then switch to the rite end for the ranger hubs??

or can I get some hubs that would fit the f150 shafts??

also I need a diff with out vacume disconnect rite??

I can pick up one of these 8.8's for about 200 bucks

and there are only three solid mounts, (no moving parts) and 2 of the 3 mounts are already made...lol

should be alot easier than an sas...lol I wouldnt have to mess with steering

any and all help and comments are appreciated

here are some more pics of the 8.8

the tube looks like it bolt on instead of just press in, i think it has 28 splines instead of 27 like the d 35

its the same diff thats in the new raptors

befor you say not enough room... I believe it will fit in my case, first I have an RCD lift so that gives me 5 more inches of up and down room

I also plan on gettin the dixon bros kit so it would be 4.5 inches wider per side, so I think the cv's would have enough room (not hit coilovers)

two of the mounts on the 8.8 are the same style mounts as on the d35

here are some comparison pics

8.8

d35

notice on the 8.8 the mount on top of the diff is closer to the edge with the diff cover than on the d35, so I know I have enough room on the diff cover side

the mount is also set higher on the diff than on the tube (more so than on the d35)

this makes me think that I can use the stock mount for the diff side and use the rcd drop bracket on the tube side

but enough with the quessing, so today I stoped by the ford dealership and crawled under an f150 with a tape in my hand...

from the center of the mount on top of the diff to the bottom of the diff it is 12 inches

on my ranger from the stock mount to the bottom of the diff is 14 inches (including rcd drop bracket)

wich is good because the d35 practicaly sits on top of the rcd cross member, so I have enough room up and down

the 8.8 is 12 inches from diff cover to driveshaft flange, that is the same as the d35 so I may be able to use my superlift drive shaft (or get one that is the same length)

of course I would have to get the tube side shortend the 8.8 is 30 inches wide and the d35 is about 21

so does anybody know where I can send the tube to get it shortend??? or have one made?

think I could get some cv's custom made to go from the 8.8 bolt on side and then switch to the rite end for the ranger hubs??

or can I get some hubs that would fit the f150 shafts??

also I need a diff with out vacume disconnect rite??

I can pick up one of these 8.8's for about 200 bucks

and there are only three solid mounts, (no moving parts) and 2 of the 3 mounts are already made...lol

should be alot easier than an sas...lol I wouldnt have to mess with steering

any and all help and comments are appreciated

here are some more pics of the 8.8

#3

HAHA....I've had dirty thoughts of doing the same thing. I think the concern area would be where the CV pivot point is. If you toss in the Fifty axle on even the DBR arms, it's gonna wanna bind because of the differing pivot points. My idea in my head to make it work is to have the Fifty axle modified and have the long side shortened. To overall, make it as close to the ranger width axle as possible. Then beyond that, I think just mounting of it is easy cake even if new frame bracketry needs fabbed. I really don't think there's room for the 8.8 front in the crossmember, even if the truck's lifted with a drop kit.

BUt...idk if you can weld to pop aluminum.

In short, I'm happy I'm not the only one with horrible dirty thoughts like this. haha.

BUt...idk if you can weld to pop aluminum.

In short, I'm happy I'm not the only one with horrible dirty thoughts like this. haha.

#5

Join Date: Oct 2007

Location: Corvallis, OR/Seattle, WA

Posts: 1,390

Likes: 0

Received 0 Likes

on

0 Posts

#6

thats exactly why im saying it. not trying to kill the idea or anything but realistically......ya.....

#7

#8

#9

#10

#11

I imagine shortening the housing to ranger width(shorten that long side), shorten the internal half shaft, most likely a custom length set of CV's and possible outer joint modification to fit the Ranger hub. Sure, it's lots of custom work and quite a bit of money, but if you got a buddy at an axle shop or race shop...should be able to be done with relative ease. And all this shortening of the tube is if you can actually weld to pop alum. Other than that, the swap appears to be almost bolt-on from what I've seen...the existing bracketry and drop brackets from the Ranger look to bolt-on to the 8.8 front. I was thinking while looking at a 04+ Fiddy front end that was torched off sitting on the ground. lol.

**side note: regarding the outer CV possible issue...would be really really really neat to figure out a way to adapt a set of like D44 Warn Premiums to it.

And FWIW, the buddy of mine that does custom suspension work out of his shop, told me the most expensive part of making a long travel IS the custom CV's. Roughly $2500 parts and labor from my buddy do to the work. Tubular upper and lower arms, rear brace, CV's, springs/c-o's. A few of the trucks he's built makes the trek to Baja every year. He's been hounding me for years to drop my truck off! lol.

**side note: regarding the outer CV possible issue...would be really really really neat to figure out a way to adapt a set of like D44 Warn Premiums to it.

And FWIW, the buddy of mine that does custom suspension work out of his shop, told me the most expensive part of making a long travel IS the custom CV's. Roughly $2500 parts and labor from my buddy do to the work. Tubular upper and lower arms, rear brace, CV's, springs/c-o's. A few of the trucks he's built makes the trek to Baja every year. He's been hounding me for years to drop my truck off! lol.

#13

I'm going back on my width concern...

Of course, I'm not entirely sure the disadvantages because i'm not that knowledgeable on it, but I never see trucks who's inner CV joint isn't roughly in-line with the upper and lower arm joints. I think because they aren't in roughly the same position and on the same 'circle', it'll cause some bindage. Again...not too sure.

But even then, if you move the upper and lower arm mounts outward to compensate for the wider axle, you'd have a truck thats as wide or even wider than yours on just stock length arms. Imagine that with the DBR arms!

**had another weird idea... F150 the entire front end! Axle, cv's, knuckles, brakes, hubs, the works. Make the arms fit the ranger.

Of course, I'm not entirely sure the disadvantages because i'm not that knowledgeable on it, but I never see trucks who's inner CV joint isn't roughly in-line with the upper and lower arm joints. I think because they aren't in roughly the same position and on the same 'circle', it'll cause some bindage. Again...not too sure.

But even then, if you move the upper and lower arm mounts outward to compensate for the wider axle, you'd have a truck thats as wide or even wider than yours on just stock length arms. Imagine that with the DBR arms!

**had another weird idea... F150 the entire front end! Axle, cv's, knuckles, brakes, hubs, the works. Make the arms fit the ranger.

#15

HAHA....I've had dirty thoughts of doing the same thing. I think the concern area would be where the CV pivot point is. If you toss in the Fifty axle on even the DBR arms, it's gonna wanna bind because of the differing pivot points. My idea in my head to make it work is to have the Fifty axle modified and have the long side shortened. To overall, make it as close to the ranger width axle as possible. Then beyond that, I think just mounting of it is easy cake even if new frame bracketry needs fabbed. I really don't think there's room for the 8.8 front in the crossmember, even if the truck's lifted with a drop kit.

BUt...idk if you can weld to pop aluminum.

In short, I'm happy I'm not the only one with horrible dirty thoughts like this. haha.

BUt...idk if you can weld to pop aluminum.

In short, I'm happy I'm not the only one with horrible dirty thoughts like this. haha.

of course I would have to get the tube side shortend the 8.8 is 30 inches wide and the d35 is about 21

i was going to have some one make me the tube,

so i would only need to get one mount made (the one near the drive shaft)

the rest would be bolt on wich i can do

I do want to put a solid axle under the front but having a jacked up prerunner would be cool also, thats why I put it in new ideas section

i know it would not be the best desert runner (taller than should be) because im adding it to the rcd,and wouldnt be the best rock crawler not enough travel for serious stuff

but it would be a good medium all around truck, and would be alot more capable than stock, 90 percent of its life is spent on the street, 14 inches of wheel travel is alot on any daily driver I think the raptor only has 12 or 13

plus I am growing fawnd of the fiberglass look, I would call it the 8.8 (you know cause it would have them front and back..lol)

I think I could get away with 36's (with the fiberglass plus 5 inches of lift), the front diff should hold up to that I see alot of f150's with 36's

even if I sas it I would want to throw some glass on it so I can keep it low as possible to the ground but still have good travel with no rubbing

#16

this guy looks like he might be able to make me a tube

U.S. Manufacturing Corporation : Current Products

or maybe these guys

US Axle Manufacturing - Providing Axles and Shafts Reducing Your Cost & Improving Your Performance

U.S. Manufacturing Corporation : Current Products

or maybe these guys

US Axle Manufacturing - Providing Axles and Shafts Reducing Your Cost & Improving Your Performance

#18

#19

^^Yep! I've always wanted to ditch my bodylift, add the DBR kit to my Superlift, and run like 37's. lol.

And even then, the DBR kit adds approx 3"-4" of front lift because of those arms and depending on where you got the coil set at.

I know this is a little crazy and will be alot cheaper than trying to find a shop that messing with alum, have you thought about converting a rear ranger axle, putting in reverse cut gears, cutting it to width, figure out the end, and welding on the associated parts?? Maybe even just make the outers just like they would be on the rear application on the ends(seals, bearings), but slide in the shortened Fiddy half shafts? IDK...I like to think and it hurts! lol. But I do like brainstorming.

Of course, I havn't a clue if those front axles are E-clips or C-clips and that'll sorta have to determine what carrier you put in.

And even then, the DBR kit adds approx 3"-4" of front lift because of those arms and depending on where you got the coil set at.

I know this is a little crazy and will be alot cheaper than trying to find a shop that messing with alum, have you thought about converting a rear ranger axle, putting in reverse cut gears, cutting it to width, figure out the end, and welding on the associated parts?? Maybe even just make the outers just like they would be on the rear application on the ends(seals, bearings), but slide in the shortened Fiddy half shafts? IDK...I like to think and it hurts! lol. But I do like brainstorming.

Of course, I havn't a clue if those front axles are E-clips or C-clips and that'll sorta have to determine what carrier you put in.

#20

^^Yep! I've always wanted to ditch my bodylift, add the DBR kit to my Superlift, and run like 37's. lol.

And even then, the DBR kit adds approx 3"-4" of front lift because of those arms and depending on where you got the coil set at.

I know this is a little crazy and will be alot cheaper than trying to find a shop that messing with alum, have you thought about converting a rear ranger axle, putting in reverse cut gears, cutting it to width, figure out the end, and welding on the associated parts?? Maybe even just make the outers just like they would be on the rear application on the ends(seals, bearings), but slide in the shortened Fiddy half shafts? IDK...I like to think and it hurts! lol. But I do like brainstorming.

Of course, I havn't a clue if those front axles are E-clips or C-clips and that'll sorta have to determine what carrier you put in.

And even then, the DBR kit adds approx 3"-4" of front lift because of those arms and depending on where you got the coil set at.

I know this is a little crazy and will be alot cheaper than trying to find a shop that messing with alum, have you thought about converting a rear ranger axle, putting in reverse cut gears, cutting it to width, figure out the end, and welding on the associated parts?? Maybe even just make the outers just like they would be on the rear application on the ends(seals, bearings), but slide in the shortened Fiddy half shafts? IDK...I like to think and it hurts! lol. But I do like brainstorming.

Of course, I havn't a clue if those front axles are E-clips or C-clips and that'll sorta have to determine what carrier you put in.

and I dont see why the tube has to be made out of alum. a steel one would bolt on just the same

#21

#24

Thread

Thread Starter

Forum

Replies

Last Post

82racin

General Ford Ranger Discussion

13

04-12-2011 01:04 AM

4x4RangerOffroad

Snapshots

32

07-08-2010 10:40 AM